NIST asks industry for custom printed circuit boards for laser stabilization and control

GAITHERSBURG, Md., 23 May 2013. U.S. government researchers are asking industry to build 20 custom printed circuit boards for laser stabilization and control as part of to develop optical frequency combs for enhancing infrared spectroscopy, distance measurement, high-speed telecommunications, and other applications.

The National Institute of Standards and Technology (NIST) in Gaithersburg, Md., issued a solicitation this week (NB686010-13-02490) for custom circuit boards as part of the Fiber Sources and Applications project of the NIST Quantum Electronics and Photonics Division in Boulder, Colo.

NIST scientists will use the laser stabilization and control boards for optical frequency combs, which convert a laser source containing one frequency of light into pulses that include thousands of frequencies.

This project aims to develop the technology for a growing list of applications, NIST officials say. Using a comb working at optical telecommunications wavelengths, project physicists have transmitted signals from next-generation optical atomic clocks across hundreds of kilometers, for example.

Scientists have demonstrated how pairs of combs can increase by a factor of one hundred the speed of infrared spectroscopy for chemical analysis, while also enhancing sensitivity. Frequency combs also promise to provide extremely accurate distance measurements and to assess the quality of high-speed telecommunications signals with unprecedented precision.

For their continued research, NIST scientists must build custom lasers to push the limits of laser stabilization and control. Digital servos make these lasers reliable enough to implement multi-channel complex transfer functions and automatic lock acquisition.

The custom printed circuit boards researchers need for this project perform high-speed, low-noise analog-to-digital and digital-to-analog conversion to build digital servos for feedback corrections of laser frequency and amplitude fluctuations.

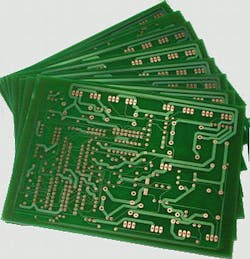

NIST scientists need a contractor to build 20 copies of a custom assembled board. The solicitation involves fabricating the boards; buying the components; and assembly.

The boards must measure 4 by 5 inches, have four layers, and be made of FR4-grade glass-reinforced epoxy. the boards must be 62 mils thick, with one-ounce copper weight, with green solder mask and while silk screen finish on both sides. SMT components must be machine-placed.

Companies interested should email quotes no later than 24 May 2013 -- this Friday -- to NIST's T. Marks at [email protected]. Include complete company name, address, telephone, and fax number.

More information is online at https://www.fbo.gov/spg/DOC/NIST/AcAsD/NB686010-13-02490/listing.html.