Chasing the goal of an efficient battlefield laser

Scientists and engineers in government, industry, and academia are researching methods and technology to create a more efficient laser for use as a weapon on the battlefields of the future.

By John McHale

The massive Airborne Laser is the laser weapon headline grabber for the U.S. military, touting its ability to destroy incoming missiles in their boost phase from the confines of a Boeing 747 jumbo jet.

However, U.S. Department of Defense researchers point out that bigger is not always better when it comes directed-energy laser weapons. Its goal is to develop a laser small enough and sufficiently power-efficient for tactical application as air-to-air combat weapons for jet fighter aircraft, says Roy Hamil, director of the laser division at the Air Force Research Laboratory’s Directed Energy Directorate at Kirtland Air Force Base in Albuquerque, N.M.

Hamil cites the Lockheed Martin AC-130 gunship as another example. That aircraft is already packed with heavy firepower, and the warfighters who operate it would be loath to dump their current arsenal just to fit a laser weapon onboard, he says. Therefore, the task for Hamil, his team, and the military industry is to develop a tactical laser compact enough to mesh in with this type of weapons application, he adds.

Lasers

A laser beam is one form of directed energy-similar in concept to sunlight focused through a magnifying glass, a directed burst of microwave energy, or a bullet fired from a gun. Laser is an acronym for light amplification by stimulated emission of radiation.

Lasers emit flashes of light, called photons, when an excited atom releases excess energy and returns to its preferred ground-state energy level. A laser beam results when a large collection of the same type of atoms produces photons nearly simultaneously.

In a beam, the photons move in step, or in phase, with each other and travel in the same direction, called coherence, Kirtland officials say. The laser system concentrates the beam by collecting, optically manipulating, and amplifying the emitted photons, and propagating the beam at a specific wavelength, which depends on the type of atom used.

Thermal management

One of the biggest problems with lasers is how to get rid of the excess heat they generate, AFRL’s Hamil explains.

Air Force scientists are looking at various materials that are highly conducive to heat dissipation, says Don Seeley, U.S. Army Representative at the High Energy Laser Joint Technology Office in Albuquerque, N.M.

“The crux of the issue with solid-state lasers is where does the power come from, how much power can be obtained, and how big a laser is needed to obtain lethality effectiveness, says Michael Booen, Raytheon’s vice president of directed-energy weapons in Tucson, Ariz.

The bottom line: the more efficient a laser, the less power it consumes, and the less excess heat it generates.

Efficiency

Efficient lasers would solve the low-power, size, and thermal-management problems of today’s lasers, Hamil says. “We are still slugging away,” with intermediate goals of finding efficiencies of 25 to 30 percent.

One type of laser that can achieve this is a solid-state laser, specifically fiber lasers. Their big research focus is on combining fiber strands to improve efficiency, he says.

Solid-state lasers (SSLs) use a crystalline or glass material doped with an ion, which is the lasing species, according to Northrop Grumman Space Technology experts in Redondo Beach, Calif. These lasers use flashlamps or diodes to pump the ions to excited levels, which then emit radiation. Experts have scaled these lasers to relatively high power levels for government and commercial applications.

The most common SSL is based on neodymium (Nd) doped into crystals such as yttrium aluminum garnet (YAG). Nd:YAG lasers emit radiation at 1.06 nanometers, which transmits well through the atmosphere.

Although not as powerful as their chemical counterparts, solid-state lasers are suited to defense missions such as destroying and illuminating targets for air defense, mine destruction, ship protection, and optoelectronic warfare, Northrop Grumman officials say.

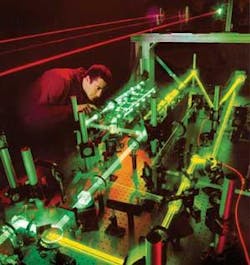

Combining the fibers

Getting the fibers to combine the way researchers want is the “current bugaboo these days,” Hamil says. AFRL Kirtland is building a testing facility to do just that, he adds.

Plans are to set up 19 fiber channels to test the technology, with actual fielding or demonstrations of this type of laser at least a decade away, Hamil says.

Several companies are working on solutions for this too, but AFRL officials wanted their own facility to help accelerate the process.

The efficiency of the test facility will improve once efficient laser diodes are available. Currently experts at the Defense Advanced Research Projects Agency (DARPA) in Arlington, Va., have a program with this focus, Hamil says. It is called the Super High Efficiency Diode Sources (SHEDS) program, which seeks to achieve 80 percent electrical-to-optical efficiency from stacks of semiconductor diode laser bars, Hamil says.

The spectral range of interest for this program is 880 to 980 nanometers-the range for pumping directly into the upper laser level of Nd and Yb:YAG lasers, DARPA officials say. Aluminum-free materials are considered the best for these devices.

Future laser sources

AFRL’s Hamil is also looking away from fiber lasers at other possible materials and solutions to improve laser efficiency.

One solution that shows promise-if not government funding-is alkaline-metal lasers. A team at the Air Force Academy in Colorado Springs, Colo., recently demonstrated an alkaline-metal laser with 40 percent efficiency, using rubidium and cesium material, Hamil says.

Researchers at Lawrence Livermore National Laboratory in Livermore, Calif., have developed an optically pumped 795-nanometer emitting-resonance-transition rubidium (Rb) laser. It is potentially the first of what could become a new class of diode-pumped lasers-those using alkali vapors as gain media, Laboratory officials say.

A continuous-wave Ti:sapphire laser currently pumps the Rb laser to emit as much as up to 500 milliwatts of single-transverse-mode 780-nanometer light-qualities that laser diodes can achieve.

The Rb laser’s room-temperature vapor cell also contains helium and ethane buffer gases. The Rb laser cavity includes a reflective angled thin-film polarizer, while the laser’s output is diffraction-limited with a purely s-polarized output.

The laser emits as much as 30 milliwatts with a slope efficiency of 54 percent. Other potential diode-pumped alkali lasers include cesium pumped at 852 nanometers and emitting at 895 nanometers and potassium pumped at 766 nanometers and emitting at 770 nanometers. Diode-pumped versions of these lasers that operate at high power will be possible, say the researchers.

High Energy Laser JTO

Officials at the High Energy Laser Joint Technology Office (JTO) in Albuquerque, N.M., will award the 100-kilowatt solid-state laser later this year as part of the Joint High Power Solid State Laser (JHPSSL) program.

The first step toward a 100-kilowatt laser was the 25-kilowatt contract, won by Raytheon Missile Systems in Tucson, Ariz. “This contract was a big step on the path to a 100 kilowatt laser, which is truly weapons grade,” Raytheon’s Booen says. “The 25-kilowatt laser will represent an initial laser capability with promising military utility.”

Right now the JHPSSL is looking at demonstrating lasers at 25 kilowatts, with 100 kilowatts obtainable in a couple of years, Booen says. However, these are laboratory lasers and require additional system engineering before they can deploy in the field.

Raytheon’s High Energy Laser Lab in El Segundo, Calif., is supporting development with the company’s Directed Energy Weapons product line, based in Tucson, Ariz.

Raytheon’s High Energy Laser team, with support from HRL Laboratories LLC in Malibu, Calif., has performed solid-state laser research and development in three areas: diode- pumped lasers, Yb:YAG (ytterbium YAG) material for lasers, and coherent change detection, which makes the most of high-quality beams. All these developments support the creation of small, efficient lasers well suited to weapons.

Another type of laser that JTO experts are pursuing is a free-electron laser, a bulky device with practical applications only to naval surface ships for shooting down incoming missiles, Seeley says. The free-electron laser has efficiencies of 20 to 30 percent but needs a big platform, he says.

The U.S. Marine Corps has a high-energy laser application for small special-forces sensor applications, Seeley says. The U.S. Army, meanwhile, is looking at ways to integrate solid-state lasers into Future Combat Systems armored vehicles like main battle tanks, he says. It would destroy incoming artillery rounds like mortars, he adds. The Air Force is obviously looking at a long-term goal of lasers for air combat, and the best platform would be the future F-35 Joint Strike Fighter, Seeley says, adding that most of these applications are 10 to 15 years away.

One thing not being done with laser development is to get low-power lasers in the hands of warfighters now so they can work with them and discover capabilities researchers may not even think of, Raytheon’s Booen says.

Low-power lasers in the 25-kilowatt range are mature enough now for warfighter demonstration, Booen says.

These lasers may not destroy a powerful cruise missile, yet fired from an aircraft the beam could defeat surface-to-air and air-to-air missiles, he says.

Booen says that Raytheon is not concerned with the specific laser but with the tactical utility of it for the warfighter. “We are laser-agnostic,” he says. Raytheon is also developing a high-energy laser application for the U.S. Navy to locate and track, he says.

Princeton Lightwave awarded additional funding for eye-safe, high-power solid-state lasers

The U.S. Department of Defense (DOD) High Energy Laser Joint Technology Office (JTO) in Albuquerque, N.M., awarded Princeton Lightwave Inc. (PLI) in Cranbury, N.J., second-year funding to continue developing highly scalable eye-safe solid-state lasers using indium phosphide (InP) diode pumping with ultra-low photon defect.

Central to this broad agency announcement program from the DOD is the development of stacks of InP diode-pumped laser arrays with high output powers, PLI officials say. These laser stacks will be optimized for pumping an Er:YAG gain medium at wavelengths close to the solid-state laser emission wavelength. Such a design using resonance pumping will reduce undesirable heating of the gain medium and allow for the scaling of the laser system to multi-kilowatt outputs while maintaining high beam quality, company officials say.

The second year of program support will enable PLI and its research partners at the Army Research Laboratory in Adelphi, Md., to demonstrate a 1-kilowatt eye-safe Er:YAG solid-state laser.

“The transition to InP-based long- wavelength pump lasers is a natural progression for the next generation of eye-safe solid-state and fiber lasers,” says Dimitri Garbuzov, PLI’s chief scientist. “In addition to alleviating active media overheating, the use of InP-based pump sources avoids a critical problem inherent to GaAs diode lasers associated with the degradation of the diode-laser mirror facets. The photon flux for InP pump lasers can be several times larger than that of traditional GaAs-based pumps at comparable device lifetimes.”

“PLI’s achievements during the first year of this JTO-sponsored program included the first demonstration of 100 W from a diode-pumped Er:YAG solid-state laser emitting near 1.65 microns, and dramatically increased output power at 1530 nanometers from InP pump- laser bars,” says PLI’s chief technology officer, Mark Itzler. “We are excited about the prospects for this program’s second year, and we look forward to surpassing 1-kilowatt power levels with this solid-state laser technology.”

For more information visit www.princetonlightwave.com.

Nufern introduces latest in a series of polarization-maintaining erbium/ytterbium double-clad fibers

Officials at Nufern in East Granby, Conn., announced the release of the latest fiber in a series of Panda-style polarization- maintaining (PM), erbium-ytterbium (Er:Yb) co-doped, double-clad products.

Nufern’s PM-EYDF-7/130 is targeted at high-power (energy) fiber-laser and optical-amplifier applications requiring polarized output at an eye-safe wavelength of 1,550 nanometers.

Nufern’s proprietary rare-earth doping technology helps deliver Er:Yb co-doped fibers with power-conversion efficiency. The Panda-style PM configuration enables the design of lasers and amplifiers with linearly polarized output.

“The design and release of the PM-EYDF-7/130 was inspired by a recent increase in demand for such fiber into laser and amplifier applications like lidar,” says Andy Held, vice president of sales and marketing for Nufern. “In fact, this market is so interesting that we’ve introduced an amplifier module based on the same fiber.”

“Much of the recent attention on fiber lasers has focused on ytterbium-doped fibers operating around the 1.06-nanometer wavelength, much the same wavelength as Nd:YAG solid-state lasers,” says Bryce Samson, vice president of business development at Nufern. “Advances in fiber technology and high-brightness diode pumps have enabled fiber lasers to deliver well over a kilowatt continuous-wave power and megawatt peak powers, both with near-diffraction-limited beam quality.

“For military applications, one of the main attractions of the technology is the very high electrical-to-optical efficiency for the Yb-doped fibers, enabling fiber lasers with wall-plug efficiencies in excess of 20% to be delivered,” Samson continues. “However, progress on power scaling fiber devices at 1.5 µm (erbium) and 2 µm (thulium) has been much slower-two wavelength bands of importance because of their eye-safe classification potentially very important in many military applications. Recent work to improve the intrinsic fiber properties at these wavelengths has enabled single-mode peak powers around 35 kilowatts at 1.5 µm and optical slope efficiency for fiber lasers around 2 µm in excess of 65 percent with further improvements at both these key wavelengths on the horizon.”

For more information, visit www.nufern.com.

Lockheed Martin-developed Airborne Laser Beam Control Fire Control system completes initial flight testing

The Beam Control Fire Control system from Lockheed Martin for the Airborne Laser (ABL) program, which is managed by the U.S. Missile Defense Agency, has completed initial flight testing.

Experts demonstrated the low-power passive capabilities of the Beam Control Fire Control system at Edwards Air Force Base, Calif. In this phase of testing, which began in December 2004, the Beam Control Fire Control system met all major requirements during more than 20 flights aboard the YAL-1A aircraft, a specially configured Boeing 747-400F.

“The ABL Beam Control Fire Control system is one of the most advanced and complex optical systems ever designed,” says Linda Reiners, vice president of Missile Defense Systems, Lockheed Martin Space Systems Company. “Through our extensive test activities this year, we have been able to validate the performance of the system in the stressing environment of flight.”

This testing phase verified the system’s target tracking capability and its ability to align the high-energy laser’s full optical path in the dynamic environment of flight. “This major milestone is a testament to the quality and thoroughness of the end-to-end ground testing of the system prior to its installation on the aircraft,” says Tom Pavelko, ABL program director, Lockheed Martin Space Systems Co. in Sunnyvale, Calif.

Other accomplishments included collection of data in the flight environment to verify the jitter performance of the Beam Control Fire Control system and the in-flight exposure of the flight turret assembly’s conformal window, the technically sophisticated optical glass through which the laser will pass. Any effects by the reconfigured nose, on either the aircraft handling or air parameter measurements for pilot use, were carefully calibrated. Integrated operation of the system with the battle management system was also validated.

The tests built on ABL program milestones achieved in 2004, including first flight of the Beam Control Fire Control system and first light of the high-energy laser.

In the next phase of the Beam Control Fire Control system, the two illuminator lasers will be installed and active ground- and flight-testing will be conducted at Boeing’s Wichita, Kan., facility.

Lockheed Martin delivered the Airborne Laser (ABL) Flight Turret Assembly (FTA) at the end of last year.

The FTA comprises the flight turret ball, containing a 1.5-meter telescope beam director and the conformal window, and its lightweight composite roll-shell structure that covers and protects the optics when they are not in use. It is the FTA that distinguishes the ABL aircraft from any other Boeing 747. It is the distinctive “nose” of the aircraft from which the high-energy laser will be “fired” at threat missiles, Lockheed Martin officials say.

The flight turret ball came from subcontractor L3-Brashear in Pittsburgh, Pa. The turret activity focused on testing of the outer gimbal controls using a surrogate turret configuration and regression testing of the flight ball. The testing using the surrogate configuration (surrogate ball and flight roll shell) verified that the gimbal-or rotational-system functions properly and reduced risk prior to integration of the flight ball, which took place in June. Following integration of the flight ball, the flight turret was subjected to a thorough set of performance tests prior to shipment to Edwards.

The world’s first airborne megawatt-class laser weapon system, ABL is designed to detect, track, and destroy hostile ballistic missiles in the vulnerable boost phase of flight. Boeing is the ABL industry team leader, aircraft provider and weapon system integrator. Northrop Grumman provides the high-energy laser segment. Lockheed Martin provides the Beam Control Fire Control system, which will accurately point and focus ABL’s high-energy laser beam.

The ABL system, which flies aboard a Boeing 747-400 jumbo jet, is scheduled to take to the skies again this year and is set to shoot down its first ballistic missile in a test over the Pacific Ocean in 2005.

When a hostile missile is launched, ABL’s on-board sensors will detect the heat from the plume of the boosting missile, setting into motion a series of events, all of them computer-directed, that will culminate in the megawatt-class chemical-oxygen-iodine laser (COIL) firing its megawatt-class beam at the missile

Although Boeing Integrated Defense Systems in St. Louis is responsible for the aircraft, Lockheed Martin Missiles and Space division in Sunnyvale, Calif., constructed the turret and the optical system. The megawatt-class chemical-oxygen-iodine laser (COIL) that will destroy ballistic missiles comes from the Northrop Grumman Space Technology division in Redondo Beach, Calif. Boeing also engineered the battle-management system and is responsible for seeing that the subsystems are integrated into the aircraft. The program is under the management of the Missile Defense Agency (MDA).

Northrop Grumman to design laser for Missile Defense Agency

The U.S. Missile Defense Agency awarded Northrop Grumman Information Technology in McLean, Va., a $142 million follow-on contract for systems engineering, planning, and logistics support for its Airborne Laser boost phase missile defense program.

Under the Airborne Laser Advisory and Assistance Services contract, Northrop Grumman’s Information Technology (IT) sector will provide technical and administrative support, including understanding technical program challenges, analyzing and predicting performance and conducting optimal system-design plans for the Airborne Laser Program Office, Kirtland Air Force Base, N.M., through 2009.

Additional work on the contract includes analysis, systems engineering, and modeling and simulation for the chemical oxygen-iodine laser device, which causes structural damage to a target missile, and the beam control system, which senses the target, selects an aim-point, and directs the laser to that aim-point. The beam control system also senses and corrects for distortions caused by the atmosphere along the beam path.

Northrop Grumman IT will also help analyze system tests, provide administrative support for security and personnel and support the Missile Defense Agency’s airborne sensor program operations.

The Northrop Grumman IT team includes the following major subcontractors: AEgis Technologies Group in Huntsville, Ala.; Apogen Technologies in Springfield, Va., and New Orleans; ATK Mission Research in Santa Barbara, Calif.; MZA Associates Corp. in Albuquerque, N.M.; National Security Research in Arlington, Va.; Schafer Corp. in Chelmsford, Mass.; and Science Applications International Corp. in San Diego.

From detection, to tracking, to engagement, Northrop Grumman is bringing its expertise to bear in the development of a global layered missile-defense capability. In the boost phase, Northrop Grumman leads an industry team on the Kinetic Energy Interceptors program and is developing the chemical-laser portion of the Airborne Laser.

For the Ground-based Midcourse Defense program, Northrop Grumman provides the critical Ground-based Midcourse Defense fire control/communications system.

In the area of sensors, the company is prime for the Space Tracking and Surveillance System and is currently the prime on the Defense Support Program. In modeling and simulation, Northrop Grumman is prime at the Joint National Integration Center, the nation’s premier missile-defense war-gaming center.