Design considerations for employing electronic slip rings in mission-critical military systems

By Richard Schultz and Ken McCue

In today’s high-performance defense weapons systems, systems designers are integrating high-power laser and microwave energy that have unprecedented speed and accuracy. These weapons systems search out targets such as enemy synthetic-aperture-array (SAR) radar systems or forward-looking-infrared (FLIR) systems, and can jam enemy weapons such as missiles by disrupting their radar sensors or infrared seekers.

Because the microwave or laser transmitters used in these systems are rapidly moving often faster than 360 degrees in rotation, slip ring technology is among the few solutions designers can find to eliminate cabling that would otherwise be twisted and tangled.

A slip ring is an electromechanical device that allows the transmission of power and electrical signals from a stationary to a rotating structure. A slip ring can be used in any electromechanical system that requires unrestrained, intermittent, or continuous rotation while transmitting power, analog, and RF signals and data.

Still, while the primary goal of the slip ring is to transmit the electrical signals, the physical dimensions, operating environment, rotating speeds, and economic constraints often affect the type of packaging that must be employed.

In many high-performance defense applications, the slip ring is often custom engineered to meet a customer’s specific requirements related to electrical specifications; mechanical packaging; operating environment; and cost constraints.

Electrical specifications

Since slip rings transmit power, analog, RF signals, and data through a rotating member, the number of circuits, types of signals, and the electrical noise immunity requirements of the system play an important role in determining the physical design constraints of the slip-ring design.

High-power circuits that power a laser or microwave transmitter, for example, require large conductive paths and broad spacing between the paths to increase dielectric strength. Analog and data circuits that sense position and control modulation also require care in their design to minimize the effects of cross-talk or interference between signal paths-even though these circuits are physically narrower than power circuits

For low-speed, low-current applications, a gold-on-gold wiper/ring combination can be employed. This combination produces the smallest packaging configurations.

For relatively high-speed and high-amperage needs, composite silver graphite brushes and silver-surfaced rings often are necessary. These assemblies normally require large package sizes such as those used in an enclosed power slip ring. Using either method, most slip ring circuits exhibit changes in dynamic contact resistance of approximately 5 milliohms.

Mechanical packaging

The packaging considerations in designing a slip ring often are not so straight forward as the electrical requirements. Many slip-ring designs require cabling and other rotating or nonrotating hardware to pass through the slip ring. These requirements often dictate the unit’s inner diameter dimensions. Signal Thru Bore-type slip rings allow the cabling to pass through the slip ring.

Other designs, such as those in wich aerodynamics or radar avoidance (stealth) are critical, require a slip ring to be extremely small in diameter, or of very low height. In other cases, such as in confined environments like main battle tanks or submarines, the space available for the slip ring is limited. This can require the slip-ring components to be provided as individual, unhoused components.

Another option is to integrate the slip-ring components with a motor, position sensor, or connectorized in an integrated package. This can eliminate the packaging space and cost of a variety of devices. Increasingly, systems integrators are shifting their requirements to these integrated packages, which enable them to outsource the complete servo system rather than source components from numerous vendors and design and assemble the integrated assembly.

Operating environment and cost

The environment in which the slip ring must operate has an influence on the slip-ring design in many ways. Rotational speed, temperature, pressure, humidity, shock, vibration, and exposure to corrosive materials influence the bearing selection, exterior material selection, flange mounts, and even cabling choices. Lightweight aluminum housings are often used to house the slip ring, although when warranted, stainless steel construction may be necessary.

The electrical, mechanical and operating requirements all drive the cost of the slip ring. By drawing from a broad array of slip-ring design technologies, novel electromechanical packaging concepts and employing a state-of-the art vertically integrated manufacturing operation, a slip-ring manufacturer can design and manufacture a cost-effective solution optimized to its customer’s performance requirements.

How a slip ring works

A slip ring is a rotary coupling used to transfer electric current from a stationary unit to a rotating unit. This is accomplished by either holding the center core stationary while the brushes and housing rotate around it, or holding the brushes and housing stationary while the center core is allowed to rotate.

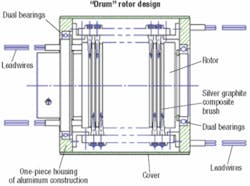

One example of a slip ring is the more common “drum” rotor design (see figure). The rotor is typically the inner portion of the slip ring while the stator, the stationary portion, is the outer portion. The slip ring has a silver graphite composite brush on a silver-surfaced ring, which is typically used for power transmission. The same construction method is used for signal circuits. For these applications, generally a gold-on-gold wiper/ring combination is appropriate. Either method provides low dynamic resistance, minimizing circuit noise into the 5 milliohm range.

Dual bearings are used in a one-piece housing of aluminum construction for stability and accuracy of bearing run-out. A cover can provide either dust or environmental sealing.

To eliminate misalignment between the slip-ring bearings and the system bearings, it is never advisable for the customer to hard mount to both the rotor and stator of the slip ring. Electro-Miniatures can design-in flanges, mounting holes, or taps and slots in the rotor and/or stator to achieve successful mounting results.

The type, gage, and length of leadwires should be specified. Connectorization is an available option and the leadwire exit pattern can be chosen to match the interface requirements.

Richard Schultz has worked in the slip-ring industry for more than 40 years and is currently director of engineering at Electro-Miniatures Corp. in Moonachie, N.J. He holds a B.S. degree from Kean University in Union, N.J.

Ken McCue has worked in the slip-ring industry for the last 17 years, as director of quality for 15 years and currently as director of programs for Electro-Miniatures Corp. He formerly was an engineer for Kearfott Guidance and Navigation Corp., and holds is BS in mechanical engineering from the College of New Jersey in Ewing N.J.