Aitech brings COTS to space

By John McHale

CHATSWORTH, Calif. - Leaders at Aitech Defense Systems Inc. in Chatsworth, Calif., are bringing the economic strategy that changed military procurement to the space market.

The commercial-off-the-shelf (COTS) initiative, launched by the U.S. Department of Defense more than a decade ago, brought new economies of scale to the defense market. Defense programs were directed to buy commercial technology wherever and whenever possible-ensuring the latest technology at the best cost.

Yet certain harsh environments precluded the use of commercial parts without significant testing and qualification. The last frontier for COTS is space, says Doug Patterson, vice president of sales and marketing for AiTech.

Traditionally the space market has had a “grow your own” approach, which can be very costly because customers are buying parts in very low volumes, Patterson says. Companies such as BAE Systems and Honeywell charge exorbitant amounts because they have to pay so much for the product and for testing. Aitech faces the same testing cost, but because “we buy parts in bulk that amortizes the cost and we pass that savings on to our customer,” he explains.

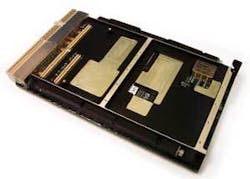

Aitech’s radiation-tolerant, space-qualified single-slot, 3U Compact (cPCI) single-board computer (SBC) is an example. The board provides an increase in performance of as much as five times and a cost reduction of as much as two times when compared to the point-driven, purposed-based designs currently in use, Patterson says.

Aitech engineers perform the space-qualification testing at Indiana State University in Terre Haute, Ind., a NASA-certified facility, Patterson says. The motto is “test what you fly and fly what you test,” he adds.

Testing prices have also increased due to the impending restriction of hazardous substances (RoHS) legislation. The legislation prohibits the sale of new electronic equipment containing certain hazardous substances; manufacturers are to substitute heavy metals (lead, mercury, cadmium, and hexavalent chromium) and brominated flame retardants (polybrominated biphenyls or polybrominated diphenyl ethers) in all electrical and electronic equipment brought to market after July 1, 2006.

Patterson says his team tests for tin content to ensure that there is never more than 97 percent tin in any product, because at more than 97 percent whiskering can occur. The same economy of scale applies to tin testing as to radiation testing-“because we test large volumes of products and make them available off-the-shelf, our customer gets a price break,” he explains

Tin whiskers are electroconductive filaments that resemble microscopic hairs and grow out of pure tin via a crystalline metallurgical phenomenon. The cause of tin whiskers is not completely understood, but stresses-like thermal cycling-encourage their growth.

No one knows what causes it, and even if they did, it would still occur, so it has to be tested for because it causes parts to fail in space, he adds.

While Aitech’s approach is business related, it also helps that many parts that Aitech uses, such as field-programmable gate arrays (FPGAs), are inherently rad-hard, Patterson says. Many parts claim to be space-ready but flunk testing, he adds.

Aitech’s rad-tolerant, conduction-cooled S950 is designed for manned and robotic space vehicles in harsh space radiation environments found in low-Earth orbit (LEO), high-Earth orbit (HEO), and deep-space applications. These include redundant mission computers, flight guidance and navigation computers, as well as command and data-handling computers. It is currently in use on the International Space Station, Patterson notes.

The board combines a high-performance, low-power PowerPC 750FX processor with a silicon-on-insulator (SOI) processor for reduced power consumption-typically less than 12 watts-as well as for increased processor speed and radiation tolerance. Its custom metal frame provides rigidity and shock resistance, as well as an array of stiffeners to support rugged PCI mezzanine cards (PMCs).

The S950 is rad-tolerant with a minimum board-level total ionization dose (TID) of 20 kilorad (Si). Flight units with higher TID tolerance are available upon request. In addition, the board is latch-up immune with a high linear energy transfer (LET) of 37 MeV*cm2/mg and features a low single-event-upset (SEU) rate of less than one upset per 25 years in operation at International Space Station (ISS) orbit.

The S950 features a 33 MHz, 32-bit internal PCI bus that supports single and burst transfers, and provides the interconnection to peripheral I/O, enabling fast access between the PCI devices and the host processor. The board’s external 33 MHz, 32-bit cPCI bus interface is implemented on a rad-tolerant FPGA for local processor access to cPCI resources. The board can be configured as a single-slot system controller, supporting as much as seven additional cPCI boards, or as a standard cPCI board in any other cPCI bus slot.

For more information on Aitech visit www.rugged.com.