By John Rhea

"Turning dumb bombs into smart bombs" is the way program personnel at the U.S. Air Force Research Laboratory's Munitions Directorate at Eglin Air Force Base, Fla., describe their efforts to create a new family of small, low-cost, precision-guided weapons from readily available electronics technologies.

Officials of the U.S. Army Aviation and Missile Command (AMCOM) at Redstone Arsenal, Ala., meanwhile, are focusing on a new guidance package to transform the Army's Hydra-70 2.75-inch "dumb" rocket into a weapon that not only is capable of destroying non-hardened targets, but that also is as accurate as the much more expensive Hellfire missile.

These efforts represent a new awareness inside the military services of the need to introduce precision guidance to even the most typical of weapon systems. Million-dollar-plus cruise missiles are still necessary to defeat heavily defended hard targets — particularly those with sophisticated jamming and other electronic countermeasures. Still, military experiences in the Persian Gulf and the Balkans have convinced U.S. military leaders of the need to supplement these weapons for new challenges where their use would represent overkill.

What this means for the electronics industry is an opportunity to produce large volumes of components of commercial off-the-shelf (COTS) grade and so-called "military off-the-shelf" grade — otherwise known as "MOTS" — for these expendable weapons. Experts say that moderate packaging improvements to these components will be necessary, particularly to counter the shock and vibration problems and the long shelf lives inherent in military ordnance. In addition, the potentially large volumes are intended to amortize these costs.

The new orientation, based on recent experiences in Panama, Somalia, and Haiti, is toward numerous inexpensive weapons capable of countering urban guerrillas and terrorists. This orientation is known as Military Operations in Urbanized Terrain, or MOUT, and it is beginning to dominate post-Cold-War military thinking.

The Army's Hellfire missile, for example, can hit targets at ranges of nearly five miles with accuracy of one meter. Still, these missiles cost about $54,000 in production. The existing Hydra-70 costs less than $1,000 each, but its accuracy is more than 60 meters — far too much error for MOUT-type use. Each Hellfire also weighs 100 pounds vs. 25 pounds for the Hydra-70.

The solution is to enhance the Hydra-70 with a small strapdown laser seeker and off-the-shelf inertial guidance, say members of the development team at Redstone headed by Bill Nourse. This development program is called the Low Cost Precision Kill, or LCPK. Army officials say they have "hundreds of thousands of the dumb rockets" in their inventory and are moving from wind tunnel and ballistic tests to control test vehicle flights using the AH-64D Apache helicopter.

The LCPK guided rocket initially will have two-meter accuracy, and cost $10,000. The goal of the program is to improve accuracy to one meter and reduce the cost to $8,000. There are other costs involved, however. There is also the cost of modifying the host aircraft, for example. This is projected to begin at $10,000 and eventually decline to $5,000, program officials say.

Driving down these costs is critical, because Army officials envision using the enhanced 2.75-inch rocket across virtually their entire helicopter fleet: AH-64A/D, RAH-66 Comanche, OH-58D Kiowa, MH-60L, AH-1F/W/J, SH-60, and AH-6. A team at the Aviation Applied Technology Directorate, at Fort Eustis, Va., is conducting this phase of the program. Low rate initial production of the complete system is scheduled to begin in 2006, Nourse says.

Each of the enhanced rockets will launch like a free rocket, and will track the target by laser, similar to how the Hellfire works. The next step is lock on after launch, and then home in for the kill using proportional navigation.

This focus on complementing the high-end guided weapons with relatively low-cost alternatives as the new MOUT program envisions spans all the U.S. military services. At the top are the Air Force's Conventional Air-Launched Cruise Missile (CALCM) at about $2 million each, the Navy's Tomahawk Land Attack Missile (TLAM) at about $1 million, and the Army Tactical Missile System (ATACMS) at about $900,000 in the latest variant.

The low-cost alternatives to these are the Navy's 5-inch Extended-Range Guided Munition (ERGM) and the Army's Excalibur 155 mm Precision-Guided Extended Range Artillery Projectile (XM-982), each estimated to cost about $20,000 per round. The ERGM will have a range of only 63 nautical miles, vs. 1,000 nautical miles for the TLAM, but Navy leaders envision using it to provide close-range precision-strike capability for shore-bound Marines and shore-based units.

Similarly, the XM-982 has a maximum range of only 30 miles, short of the 180 miles for ATACMS, but its justification is to provide field commanders with a precision-strike capability where collateral damage is a major consideration. Accuracy is estimated at 20 meters.

Army officials conducted a series of five preliminary tests of the XM-982 in May at the Yuma, Ariz., Proving Ground to validate the aerodynamic performance before the next phase of testing involving the projectile's guidance and control systems. The prime contractor is Raytheon Missile Systems in Tucson, Ariz., and production is set to begin in 2004.

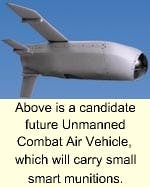

Two complementary efforts, meanwhile, envision capitalizing on electronics technology that will enable miniature munitions to attack soft, moderately hardened, and mobile targets. Heading these efforts is Mickey Duvall at the Air Force Munitions Directorate at Eglin Air Force Base, Fla. Under his Small Smart Bomb Technology program, Duvall is looking for payloads that can be carried in the Unmanned Combat Air Vehicle (UCAV) currently in the early stages of development and the planned Common Air Vehicle.

Among the technologies necessary to support the smart bomb program are low-cost laser terminal seekers, miniaturized anti-jam inertial navigation system/Global Positioning System (INS/GPS) guidance subsystems, and small, relatively inexpensive fuzes.

Duvall's rationale holds that producing miniature versions of the typical 2,000-pound dumb bombs will enable the Air Force officials to deliver three to four times as many munitions than they can with the current airlift capability. This, in turn, permits more rapid deployment, which has been a problem in recent peacekeeping operations. One of the possibilities for this technology is pre-planned product improvements to the planned Joint Direct Attack Munition (JDAM).

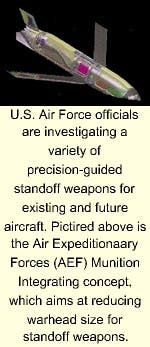

Duvall's other program, which will use similar technologies, is the Air Expeditionary Forces (AEF) Munition Integrating Concept, in which high-energy explosives, mass-focus fragmentation, and multiple-sensor fuzing aim at reducing warhead size for standoff weapons.

Two other programs at Eglin — the Anti-Material Munition (AMM) Technology and Close Air Support (CAS) Weapon Technology programs — aim at integrating laser radars, GPS, and inertial navigation into small munitions for launch from aircraft. Leading these programs is Ken Edwards. The AMM program envisions a 31-inch vehicle with a low-cost autonomous attack system (LOCAAS). This way users could launch 16 munitions from one fighter aircraft and nearly 200 from a B-1 bomber. Powered free-flight demonstration of LOCAAS is set for 2002.

The CAS effort is for existing fighters and future aircraft such as the Joint Strike Fighter, and may also support UCAVs. Among the technologies necessary are three-dimensional flash laser radar seekers, identify friend or foe (IFF) algorithms, and INS/GPS to enable a 40-mile standoff capability.

Edwards says he expects this miniature munition will be shorter than 80 inches, thinner than 7.5 inches, and lighter than 200 pounds. He estimates that jet fighters could launch this munition from as far away as 40 miles and from altitudes as high as 21,000 feet.

Experts are investigating the new technology of microelectronic and mechanical systems (MEMS) for use against hard targets. William Loose, the program manager at the Munitions Directorate at Eglin AFB, lists advantages of MEMS in reducing size and weight of fuzing, power sources, guidance and controls, sensors, and logic systems.

Other technologies will be necessary for ground-penetrating signals to characterize and locate underground facilities and identify their operations, Loose says. His group is also working on a battle damage indicator and assessment signal that can alert a smart sensor web to enable real-time battle management.

All these efforts for an entirely new layer of weapons between the top-of-the-line cruise missiles and the low layer of the dumb bombs of the past are in relatively early stages of development pending approval by the U.S. Department of Defense top management. However, they are well along in the process of the services' mission needs statements.

As the underlying requirements drift upward in the Pentagon hierarchy some of these programs should represent new opportunities for COTS and MOTS vendors. Quantities, schedules, and funding profiles should be determined as part of the process of winnowing out the duplicating efforts.

IEC ruggedizes automotive inertial sensor, GPS chips forsmart munitions

ANAHEIM, Calif. — Despite rigid requirements to withstand forces as strong as 15,500 Gs during firing, Interstate Electronics Corp. (IEC), has adapted an inertial sensor developed for the company's automotive product line for use in "smart" artillery systems for the U.S. Army and Navy.

The systems are the Navy's five-inch Extended Range Guided Munition (ERGM) and the Army's Excalibur 155-mm XM-982 howitzer projectile, both of which use shells that weigh about 100 pounds.

At launch the projectiles depend on signals from a Global Positioning System (GPS) chip to determine the flight path. If the GPS signals are jammed the navigation computer relies solely on the inertial sensor.

IEC experts packaged the inertial sensor and the GPS chip to achieve the required ruggedization through the use of specialized glues and coatings, and additional potting, company officials say. The components were tested at more than 300,000 Gs, they add.

Based on past experience in the Navy's Polaris missile program and the Air Force's air-launched cruise missiles, IEC engineers are trying to further miniaturize the GPS/inertial sensor package and get the costs below $1,000 in order to compete for other low-cost precision guided weapons programs. — J.R.

For more information, contact Interstate Electronics by phone at 714-758-4158, by fax at 714-758-4148, by post at 601 East Vermont St., P.O. Box 3117, Anaheim, Calif. 92803, or on the World Wide Web at http://www.ichome.com/.

Hardware-in-loop simulations cut flight test costs

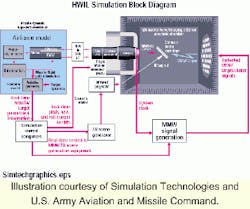

HUNTSVILLE, Ala. — Hardware-in-the-loop simulations of radio frequency (RF) missile seekers are an important low-cost alternative to flight test programs.

Engineers from Simulation Technologies Inc. are upgrading their computer system to support new submunitions programs at the U.S. Army Aviation and Missile Command's Advanced Simulation Center at nearby Redstone Arsenal.

As the weapons become more complex, so do the simulations, explains Richard Olson Jr., chief scientist at Simulation Technologies. In order to perform real-time processing of a new dual-mode millimeter wave and infrared missile simulation, company engineers are using two 24-processor Merlin systems incorporating PowerPC AltiVec-based multiprocessors. The $500,000 system was shipped in May from its manufacturer, Sky Computers Inc. of Chelmsford, Mass., a subsidiary of Analogic Corp.

The Advanced Simulation Center has been using hardware-in-the-loop missile seekers for 20 years. To support the new programs, Olson estimates he needed vector path processing performance 20 times greater than he did for any other simulations at the center.

The millimeter wave simulation involves RF signature variables, including range (time) delay, range extent, Doppler bandwidth, polarization, and angle-of-arrival. Real-time signature models for RF sources, such as complex target return, background clutter, countermeasures, and jet engine modulation, constitute the environment in which to evaluate the seeker's detection and tracking performance.

The simulation covers airborne and ground targets that the millimeter wave seekers track. The radar uses pulsed, variable frequency transmit waveforms and short radar measurement cycles, Sky officials say.

A typical real-time target model computes the deterministic range and monopulse angle of arrival (glint) signatures of complex targets composed of more than 100 RF scattering sources to create the RF environment for the simulation.

Simulation Technologies designers began with an eight-processor Merlin system from Sky last November. Sky officials estimate another $1.5 million worth of simulator computers will be necessary to support future programs. The Huntsville company had previously used an i860-based system. — J.R.

Solid-state power controllers extend weapons' unattended life

BOHEMIA, N.Y. — An inherent problem for all forms of ordnance is the necessity to remain idle for years. In these kinds of operating conditions, weapons require reliable components users can rely on to work whenever they must use the munitions.

This is particularly true of precision-guided weapons, which also have demanding requirements for the quality of the electrical power necessary to operate the complex computer systems, says Steve Friedman, product manager for solid-state power controllers at Data Device Corp.(DDC) in Bohemia, N.Y.

The pilot of a fighter aircraft does not want to have to reboot one of his onboard computers in the middle of a combat mission, Friedman notes. Yet the power controllers are one of the lowest items in any military electronics system — essentially the militarized equivalent of the electromechanical circuit breakers in private residences — and must rely on off-the-shelf technology.

DDC officials have been marketing a line of military off-the-shelf (MOTS) solid-state power controllers since they began working with the U.S. Army eight years ago on the M1A2 Abrams main battle tank, which Friedman praises as having the most modern electronics of any military ground vehicle.

This same technology is now migrating to other weapon systems, including torpedoes for a military customer in Asia that he would not name and such aircraft as the U.S. Navy's F/A-18 and the U.S. Air Force's F-16 fighter aircraft. He says he expects the U.S. Marine Corps's Advanced Amphibious Assault Vehicle to be an early user.

By MOTS Friedman means metal oxide semiconductor field effect transistors operating at anywhere from 2 to 80 amps, usually DC, but also AC, and packaged in hermetically sealed plastic modules.

These are also smart power controllers, because they can monitor the electrical current in real time and communicate with an onboard computer to update the power status via databuses such as the ubiquitous MIL-STD 1553. In an aircraft this function is done through the MIL-STD universal stores management interface, but similar interfaces are available for other vehicles and weapons.

"What this technology brings to the table is reliability, ease of maintenance, and power quality," Friedman maintains. By knowing the exact power requirements users can specify the right size wire for power distribution. The status reporting feature eases maintenance, and the soft turn-on and turn-off feature protects the computer. This also eases the demand on batteries, thus extending their useful life.

Members of the U.S. military are investing heavily in expanding 270 volt DC power systems in new aircraft, he adds and cites the RAH-66 Comanche and the Joint Strike Fighter as candidates for solid-state power controllers. — J.R.