Enabling technologies for military & aerospace electronics engineers

Sensors

TACNAV selected for Australian Light Armored Vehicles

Officials at General Motors Defense in Troy, Mich., needed a navigation system for use aboard the Australian army's Light Armored Vehicle (ASLAV) fleet. So they chose the TACNAV (tactical navigation) system from KVH Industries in Middletown, R.I.

TACNAV will retrofit the existing fleet of ASLAVs as well as new production vehicles.

"This is the first sale for KVH into Australia and reflects the growing acceptance of KVH's TACNAV product family as the tactical navigation system of choice among armored forces worldwide," claims Christopher Burnett, KVH's vice president of business development. Working with General Motors Defense KVH engineers have also equipped armored vehicles used by the U.S. Marine Corps, Canada, and Saudi Arabia, he says.

"Right now, U.S., Canadian, and British armored forces in Kosovo depend on the same TACNAV systems to maintain uninterrupted situational awareness, reduce the possibility of fratricide, and enhance overall operational efficiency," Burnett adds.

KVH TACNAV systems offer every vehicle and every force commander — whether in a command, support, or combat vehicle — 100 percent availability of position and other tactical data, even if the signals from Global Positioning System (GPS) satellites are disrupted or jammed, KVH officials claim.

In addition to interfacing with the onboard GPS, TACNAV consolidates vehicle location and azimuth, turret angle, and far target location into a single-point interface that can be transmitted via digital battlefield management systems to the force commander and the other units in the field, KVH officials add. — J.M.

For more information on TACNAV contact Jim Dodez, by phone at 401-847-3327, by fax at 401-849-0045, by mail at KVH Industries, 50 Enterprise Center, Middletown, R.I. 02842, by e-mail at [email protected], or on the World Wide Web at http://www. kvh.com.

Board products

ACT/Technico to use MEN Micro single-board computers on rugged integration projects

Officials at ACT/Technico in Ivyland, Pa., needed single-board computers (SBCs) that were inherently rugged for their real-time integration projects. So they decided to partner with experts at MEN Micro in Dallas, a subsidiary of MEN Mikro Elektronik GmbH in Nurnberg, Germany.

ACT/Technico engineers specialize in bus-based industrial and ruggedized applications using VMEbus, CompactPCI and PC bus products. Company officials plan to use MEN's products in many different types of systems, including ruggedized military systems, industrial real-time process control, telecommunications and communication applications, and others.

"There is a lot of synergy between our two companies," says Ken Grob, president of ACT/Technico. "We have used MEN technology in the past, most notably M-Modules for modular I/O. As we looked at the rest of MEN's product lines, we saw that their 3U CompactPCI SBCs offer us the capability to provide some very unique solutions to the marketplace.

"In addition the industrially hardened nature of many of MEN's computer boards as well as its PC-MIP I/O modules complemented some of the extreme environments where we were already working," Grob continues. "MEN's 3U and 6U CompactPCI and Motorola PowerPC SBCs will be particularly helpful in the telecommunications arena."

"Because many of our SBCs and modular I/O cards have already been qualified for temperature, shock, and vibration extremes in harsh conditions, ACT/Technico will be able to reduce the technology risk of its projects by eliminating much of the qualification process," says Ernest Godsey, president of MEN Micro.

ACT/Technico engineers have designed and integrated solutions for organizations such as NASA, AT&T, General Electric, Raytheon, and Oracle. Typical projects use some combination of custom designed and commercially available hardware, as well as real-time software from Wind River Systems, and LynuxWorks, MEN Micro officials say. — J.M.

For more information on MEN Micro contact Ernest Godsey by phone at 972-939-2675, by fax at 972-466-5986, by mail at 1940 Camden Way, Suite 100, Carrollton, Texas, by e-mail at [email protected], or on the World Wide Web at http://www. menmicro.com.

For more information on ACT/Technico contact Valerie Andrew by phone at 215-957-9071, by fax at 215-957-9074, by e-mail at [email protected], or on the World Wide Web at http://www.acttechnico.com.

Sensors

C-130K to have Oxley night vision

Officials at Marshall of Cambridge, England, are asking experts at Oxley Avionics to develop a cockpit night vision upgrade package for the Hercules C-130K aircraft. Royal Air Force officials have appointed Marshall as prime contractor for the upgrade.

Oxley engineers designed the Hercules upgrade package to be cost-effective while still embracing the latest technology, Oxley officials say. A typical modification includes night vision goggle (NVG) compatible floodlights, instrument pillar lamps and bridges, warning/caution indicators, and radar/communications display filters. This upgrade can also extend to all light flow legend panels.

In addition to the cockpit upgrade package, Oxley Avionics engineers have developed an exterior NVG compatible lighting package tailor-made for the Hercules C-130.

The upgrade to the 10 previous UK C-130Ks will extend to a further five aircraft and eventually to the entire C-130K fleet. Cockpit upgrade solutions are also available for other series of this aircraft, Oxley officials say.

Covers with NVG Friendly filters are also available for navigation/position lights and anti-collision lights. In addition an IR covert lighting kit is available tailored to suit customer requirements. — J.M.

For more information on Oxley Night Vision contact Brian Thomson by phone at 01229 582621, by fax at 01229 580687, by mail at Oxley Avionics, Priory Park, Ulverston, Cumbria LA12 9QG, United Kingdom, by e-mail at [email protected], or on the World Wide Web at http://www.oxley.co.uk

Test & measurement equipment

Designers at Veraxx Engineering choose RTI's StethoScope for Linux

Software engineers at Veraxx Engineering Corp. in Chantilly, Va., needed a visualization tool for monitoring and analyzing embedded and real-time Linux code. They found their solution in StethoScope for Linux from Real-Time Innovations Inc. of Sunnyvale, Calif.

Engineers at Real-Time Innovations, unveiled StethoScope for Linux, which helps software developers understand and debug complex real-time code. This latest offering extends StethoScope to the Linux operating system.

"We use StethoScope to help us streamline our real-time software development process. It's been great for monitoring and analyzing our system as it runs," says Chris Conrad, principal engineer at Veraxx Engineering. "As Linux developers, we see specialized analysis tools like StethoScope as invaluable for getting the system out on time and within specification."

Veraxx Engineering is an engineering services company supplying hardware, software, and system design requirements, with expertise in software development, flight simulation, computer architecture, avionics systems, and real-time embedded systems.

StethoScope, the real-time data monitor, lets software engineers watch any variable or memory location in their system while they run. Engineers can watch any set of variables, see peak values and glitches, trigger data collection on specific events, change variables from the host GUI, and save data to the disk. — J.K.

For more information contact Real-Time Innovations by phone at 408-734-4200, by fax at 408-734-5009, by post at 155A Moffett Park Drive, Sunnyvale, Calif. 94089, or on the World Wide Web at http://www.rti.com/.

Power electronics

Navy chooses SatCon to develop motor drive systems for DD 21 destroyers

U.S. Navy leaders needed motor drive systems for their future Zumwalt-class DD 21 land-attack destroyers. Power components from SatCon Technology Corp. in Cambridge, Mass., met their needs.

SatCon won a U.S. Navy contract to develop modular motor drive systems for the Navy's DD 21 "all-electric" ship, SatCon officials announced. SatCon experts will design and simulate a modular motor drive compatible with several different motor types, company officials announced.

Motor drives integrate electronics and controls within a motor to perform specific motor control functions. The initial study phase contract is for $200,000. SatCon recently won a $2.7 million subcontract to design and develop the integrated power conversion system for the new ship.

The Zumwalt-class destroyers are to replace the U.S. Navy Spruance-class destroyers and Oliver Hazard Perry-class frigates. These ships will be designed to handle land attack and undersea warfare operations, as well as evacuations, escort, and diplomatic tasks.

The DD 21's primary mission will be land attack support for ground forces by using its 5-inch extended-range guided munitions and 155 mm howitzers from as far away as 100 miles. A land attack missile system will extend support between 100 and 200 miles. Tactical Tomahawk missiles will be able to reach targets from 200 to 1,600 nautical miles.

"The DD 21 represents a growing trend in the conversion of vehicles and heavy machinery to 'all-electric,' thereby creating a new and broader sector for power electronics," says David Eisenhaure, SatCon's president and chief executive officer.

"The DD 21 is also a well-suited platform for demonstrating distributed power technology," Eisenhaure continues. "A ship is much like a small industrial city. It needs to generate, store, and distribute power throughout its several compartments just as a small city would. And, like a small city, it needs to respond to peak power requirements without the loss of power to any one of its compartments."

Eisenhaure says this modular motor drive concept has commercial and naval applications, as well as potential benefits to automotive and distributed power applications.

The new modular drives should be able to drive several types of motors and provide regulated AC or DC output power for uninterruptable power supplies and auxiliary power unit, company officials say. — J.K.

For more information contact SatCon by phone at 617-661-0540, by fax at 617-661-3373, by post at 161 First St., Cambridge, Mass. 02142-1221, or on the World Wide Web at http://www.satcon.com/.

Displays

Litton to provide automated bridge equipment on Army logistics ship

U.S. Navy officials needed bridge-automation equipment for a Gen. Frank. S. Besson Jr.-class U.S. Army Logistics Support Vessel. They found their solution in the Integrated Bridge System (IBS) from Litton Marine Systems in Charlottesville, Va.

The contract came from the Naval Surface Warfare Center Carderock Division. The IBS equipment will be installed on a Besson-class medium landing ships at Fort Eustis, Va., early in 2001.

Litton engineers will install a three-node Sperry Voyage Management System (VMS) with electronic chart display and information system (ECDIS), dual Decca BridgeMaster E X-band and S-band radars, a Sperry ADG3000 adaptive autopilot, a military P-Code GPS receiver, and a weather station.

The 272-foot logistics support vessels are the largest landing craft in U.S. Army service. The roll-on roll-off (RoRo) ships are for combat support and rear-area logistics. — J.K.

For more information contact Litton Marine by phone at phone at 804-974-2000, by fax at 804-974-2259, by post at 1070 Seminole Trail, Charlottesville, Va. 22901, or on the Word Wide Web at http://www.litton-marine.com/.

Software

Green Hills provides software support for Space Station microprocessors

Space systems engineers at the BF Goodrich Aerospace Space Flight Systems division needed a real-time operating system and software-development environment for their new microRAD radiation-hardened RISC processor.

They found their solution in the ThreadX real-time operating system (RTOS) and MULTI 2000 Integrated Development Environment (IDE) from Green Hills Software Inc. of Santa Barbara, Calif.

The new processor, which features fully redundant logic circuitry, is for use in a variety of in-flight space applications. The first deployment for microRAD will be the International Space Station, where the processor will be used in the express pallet assembly, which is used outside of the space station to host autonomous experiments.

Scientists from the U.S. Air Force Research Laboratory also will use MicroRAD as a network node controller, and by the Applied Physics Laboratory for instrument control in an interplanetary exploration application, Green Hills officials say.

MicroRAD is a fault-tolerant 32-bit RISC processor optimized for high-reliability in-flight space data and control electronics. Featuring fully redundant instructions and memory (EDAC or majority voted), microRAD provides an IEEE 754-compatible floating point unit, special NSA instructions, eight kilobytes of unified instruction/data cache, and an integrated MMU and DMA controller.

ThreadX is a real-time multitasking operating system with a picokernel design with fast timers and a high-speed preemption-threshold mechanism.

The MULTI 2000 IDE helps automate software development for the microRAD processor.— J.K.

For more information contact Green Hills Software by phone at 805-965-6044, by fax at 805-965-6343, by post at 30 West Sola St. Santa Barbara, Calif. 93101, or on the World Wide Web at http://www.ghs.com/.

Displays

Smiths chooses White Electronic Designs for cockpit displays

Systems designers at Smiths Aerospace of Malvern, Pa., needed rugged displays for cockpit instrumentation in commercial business jets and air transport planes where the ambient light precludes the use of conventional flat panel displays.

They found their solution in optically enhanced and environmentally ruggedized displays from White Electronic Designs Corp. in Phoenix. White engineers are using their Super Bright Low Reflection (SBLR) technology for the Smiths displays.

White is doing the work under terms of a $1.5 million production order from Smiths Aerospace, which White officials announced.

"Our relationship with White spans many years during which they have proven to be a reliable supplier of high quality parts, says Ron Decembrino, director of operations at Smiths. "We awarded this contract to White because their superior SBLR technology has been proven to provide the image quality necessary for cockpit and other avionics applications."

White designs high-density memory and multi-chip modules for data communications and telecommunications providers; ruggedized flat panel displays for commercial/military aircraft and weapons control; interface storage and retrieval devices, and electromechanical assemblies for commercial and military systems designers. — J.K.

For more information contact White Electronic Designs by phone at 602-437-1520, by fax at 602-437-1731, by post at 3601 E. University Drive, Phoenix, Ariz. 85034, or on the World Wide Web at http://www.whiteedc.com/.

Power electronics

Norwegian navy chooses submarine propulsion batteries from Exide Technologies

Leaders of the Norwegian navy submarine forces needed propulsion batteries for their Ula-class submarines. Large batteries — each of which has 480 cells and weighs more than 140 tons — from Exide Technologies in Reading, Pa., met their needs.

Exide officials recently signed a contract to begin delivering propulsion batteries from the company's Horten, Norway, plant, beginning in 2002. The contract, which is worth $12.8 million, includes technical training courses, manuals, services, installation, and testing for six batteries to power six submarines.

This battery is the only energy source for the Ula-class submarine during submerged sailing.

"The navy gave the contract to the most capable producer in the marketplace," says Rear Adm. Jan Jaeger, head of the Royal Norwegian Navy Materiel Command. "The excellent quality of the batteries from the Exide Horten plant also was a major factor in their evaluation. It was therefore a pleasure for the Navy that the contact was concluded with Exide."

Batteries from Exide's Horten plant also are going to the Royal Danish Navy's Tumleren-class submarines. — J.K.

For more information contact Exide Technologies by phone at 610-378-0500, by fax at 610-378-0824, by post at 645 Penn St., Reading, Pa. 19601, or on the World Wide Web at http://www.exideworld.com/.

Computers

Training device designers choose Concurrent Power Hawk computers

Simulation experts at Engineering Support Inc. (ESI) in Hunt Valley, Md., needed computers to power their maintenance and trainer devices. They chose the Power Hawk Series 640 computer from Concurrent Computer Corp. in Duluth, Ga.

ESI officials bought 13 of Concurrent's Power Hawk Series 640 closely coupled systems and spares for maintenance trainer devices, Concurrent announced. The value of the total contract with ESI exceeds $2 million.

"Concurrent's Power Hawk 640 was chosen for this application as the result of an ESI Technical Trade Study. The objective of the study was to provide a COTS [commercial-off-the-shelf] solution for an open system architecture that best met performance and life cycle cost requirements," says David Warner, deputy program manager for ESI's maintenance training systems at the company's facility in Summerville, S.C.

"Concurrent has demonstrated the ability to quickly customize solutions as needed, and its systems are also compatible with commercial-off-the-shelf technology," Warner says. "This superior technology, combined with Concurrent's 100 percent dedication to a total solution and excellent customer support, made Concurrent a clear choice for this simulation application."

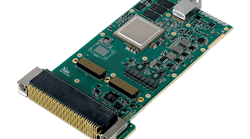

The Power Hawk 640 6U VME computer has two symmetric Motorola PowerPC 604e RISC microprocessors and can accommodate as much as one gigabyte of memory. Users can link several different Power Hawk CPU modules in multiprocessor configurations. It includes the PowerMAX OS, Concurrent's real-time UNIX-based operating system; a VME processor board; and peripherals packaged in an industry-standard 6U enclosure.

ESI is a wholly owned subsidiary of AAI Corp. in Hunt Valley, Md. — J.K.

For more information contact Concurrent Computer Corp. by phone at 877-978-7363, by fax at 678-258-4199, by post at 4375 River Green Parkway, Duluth, Ga. 30096, or on the World Wide Web at http://www.ccur.com/.