By J.R. Wilson

As U.S. military systems designers move to make more and more of their missiles and munitions "smart", they rely heavily on micro electro-mechanical systems (MEMS) technology to shrink size and cost while increasing accuracy and lethality at great distances.

Col. Nathaniel Sledge, Program Manager-Combat Ammunition Systems at the Army's Picatinny Arsenal in New Jersey, says the same technologies can be used for either smart or precision-guided munitions, although the two are not the same.

"A smart weapon distinguishes its target from the background and points to it; a precision weapon has low dispersion and hopefully high accuracy, which brings it very close to the target," he explains. "Excalibur (a 155mm precision guided, extended-range artillery round for the Army and Marines) is a carrier of munitions, a precision carrier; it can carry smart or high-explosive munitions and discriminate the target."

Commonality also is key to current programs along these lines. One of the leading efforts is the Army's Common Guidance Program, an effort to get a MEMS inertial measurement unit (IMU) to develop the next level of performance for projectile and missile programs, which also has implications for the Navy and Air Force.

"The whole MEMS IMU technology, in and of itself, is pretty much on the cutting edge and is really the only way to get to the volume we're looking for," says David Panhorst, manager for MEMS programs at Picatinny. "The state of the art today is the ring laser gyro; by going to MEMS, we can go with a sensor that is amazingly small. That's also going to be the driving force to get us to the G-survivability we need. We're trying to meld the accuracy requirement in a missile-type munition with a projectile."

Where the electronics in a missile warhead are subjected to only a few times the force of normal gravity, a gun-fired munition may experience more than 20,000 Gs. Add to that an over-pressure of around 65,000 pounds per square inch (psi) in a naval 5-inch gun and engineers must overcome a nightmare environment when designing such projectiles as the Navy's Extended Range Guided Munition (ERGM).

"The biggest technology challenge across the board is the gun-hardening aspect," acknowledges Gary Letterman, business development manager for Navy projectiles at Raytheon Missile Systems in Tucson, Ariz., prime contractor on ERGM and Excalibur. "We fire ERGM nominally at about 10,000 Gs out of the gun and Excalibur is around 14,000 Gs.

"The challenge is to build a missile that can survive this kind of shock at launch. The over-pressure also makes the structural design interesting. Our guidance section presently comprises five cards — power, mission computer, GPS, anti-jam, and IMU — so the task at hand is how do you stack these boards, keep the components on the board, and develop harnessing that won't be ripped apart when you subject it to these horrible environments."

GPS/IMU technology

With the latest in GPS/IMU technology, Excalibur is intended to hit targets as far away as 50 kilometers with a Circle of Equal Probability (CEP) accuracy of 20 meters, carrying any of three unique payloads, making it the most versatile artillery projectile in the Army and Marine Corps inventories. Officials of the U.S. Department of Defense (DOD) intend for Excalibur's accuracy to provide first round fire-for-effect capability to all current and future 155mm digitized howitzers — Paladin, M198, LW155, and compatible international systems. It also will greatly reduce the logistics trail and the number of units and personnel required in the field as the Army moves to a lighter, faster, smaller force.

"The final goal of the Army program is production of a very sophisticated system, beyond Excalibur, that has a 1 degree per hour drift rate gyro, which would enable you to fly safely from California to Hawaii. That is a much more sophisticated unit than exists today or even being planned for Excalibur or ERGM. It also is very high shock value, in excess of 20,000 Gs," notes John Foster, chief executive officer of Innovative Micro Technology in Santa Barbara, Calif., a MEMS fabrication facility.

"A big piece of what makes smart munitions possible is the ability now to make very tough, very strong and extremely precise MEMS devices that can function as accelerometers and gyros. That is what makes MEMS a requirement for this kind of navigation — you have to have something that can survive the horrific shock of being fired out of a large gun. The silicon MEMS devices we make can withstand that kind of shock."

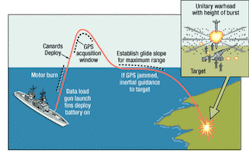

ERGM, on which Raytheon is working with the Naval Surface Fire Support office at the U.S. Naval Sea Systems Command, is intended to become a major component in the Navy's evolving littoral war concept to support forces ashore with sustained, accurate fire. While initially planned for deployment in 2004 for use in naval 5-inch guns, the same guided projectile technology will be applied to the next generation land attack destroyer's (DD21) advanced gun system.

"What we're accomplishing, I believe, will revolutionize the whole concept of naval fire and ground artillery. Today's 5-inch naval gun with a standard munition has about a 13nm range. If you go from a 54 to a 62-caliber barrel with ERGM, you can achieve more than 50nm. In terms of accuracy, standard dispersion on today's 5-inch at 13nm has a CEP of about 750m, which decreases as you decrease range; with ERGM, we are 20m CEP regardless of range," Letterman says.

"The other significant capability is multiple round simultaneous impact. For example, out of one barrel we can fire nine ERGM rounds that will land within a second and a half of each other anywhere you want — a grid pattern, different targets, whatever — because we can control the trajectory. In the old artillery days, a Marine on the ground calls in rough coordinates, then walks the rounds in until one finally hits the target, then he calls for fire-for-effect, when they start a lot of rounds. Meanwhile, of course, the enemy is digging in. With this capability, while the enemy has no idea they are about to be attacked, nine rounds land together. That is extremely lethal."

Economies of scale

While MEMS technology is making this evolution possible, the multi-service market for such munitions is expected to help drive economies of scale. The four MEMS-based artillery programs currently underway — Excalibur, ERGM, the Navy's Long Range Land Attack Projectile (LRLAP) for a new generation of 6-inch guns and what was known as the Low Cost Competent Munition (LCCM), now called the Course Correction Fuze — eventually could require 80,000 or more guidance units annually. The Army, for example, has set a goal of buying 10,000 Excalibur rounds a year, beginning in 2004, at unit costs of less than $2500.

Military developers and contractors also are looking to reduce costs by offering some of the evolving MEMS technology to commercial users, such as the automobile industry, essentially completing the development circle, as some MEMS technology came from that sector originally.

"We have make sure the military application of the technology isn't proliferated, of course, but in the auto industry the accuracy they are looking for is nowhere near what the military requires," Panhorst says of the MEMS IMU. "So we may be able to utilize that market to bring some production costs down without proliferating the accuracy capability the military systems need."

Every effort also is being made to spread the technology as widely as possible across all military services and munitions programs.

"We're looking right now at working this into the Excalibur round, which may be our first big customer. On the missile side, potentially the JDAM (Joint Direct Attack Munition). Another possibility is Common Missile. We're looking at a host of different possibilities," Panhorst says. "This is planned primarily for new systems, but part of the economies of scale may look at some fuzing applications, what we call one-time course correction fuzing, where you can screw a smart fuze onto a dumb projectile and do a course correction midway in the trajectory."

A program to convert the millions of standard artillery shells already in military inventories to "smart" munitions by utilizing MEMS-based technology would constitute a major market for manufacturers, putting military procurers in a position in which they rarely find themselves when dealing with electronic components.

"We're looking for multiple providers, again to keep the price down, but also we really feel, if we are successful, there will be a large enough market to keep two suppliers busy," Panhorst says.

HYDRA improvements

Another effort to incorporate smart technologies into existing systems is the Advanced Precision Kill Weapon System (APKWS) for the HYDRA-70 (70mm) family of 2.75-inch unguided rockets. Used by all four services, including Army Special Operations Forces, the HYDRA-70 rocket can be fired from all Army combat helicopters as well as from many fixed-wing platforms and can be fitted with a wide range of warheads, including flechette, target illumination, smoke, flare, and a high-explosive multipurpose submunition. It is a major export munition to many allied nations.

"APKWS is the umbrella program that will encompass all improvements to the HYDRA rocket family," says Carol Frazier, aviation, rockets and missiles (ARM) project manager at the Army Aviation & Missile Command (AMCOM — Redstone Arsenal, Ala.). "Block 1, which began this year, is putting a strapdown laser system on the current rocket. Future blocks will entail a new motor, new fuzing, a different warhead — capabilities to meet new future operational requirements. It may also look at a different kind of guidance package, such as GPS.

"This is to take care of softer targets; it's not an anti-tank weapon. It fills the gap between the anti-tank and an unguided rocket, which isn't very accurate. It will reduce collateral kill and provide more stowed kills with fewer rockets — I should be able to get 8 kills out of 10 rockets, depending on the targets, compared to only 1 or 2 with 10 unguided rockets."

A major goal is to maintain the HYDRA's low cost, relative to bigger missiles. Frazier says they are working with the user now to define what the future blocks should be and what capabilities are out there for Block 2, which will run from 2006 to 2008. The enabling technologies for Block 1 are lasers and the guidance and control algorithms being developed by Raytheon and BAE. General Dynamics, the systems integrator, was expected to make a downselect between the two in January.

"Both are strap-down seekers, but a lot of it is in the software they come up with to control the rocket, which was never designed to be a guided rocket," Frazier says. "Raytheon has the optics in the nose, so the data is collected directly onto the arrays and processed there. BAE's collectors are on the wings, so they use fiber optics to get the data back to their processor at the back of the guidance package, in the mid-body behind the warhead."

Raytheon demonstrated its guidance package on a 3.5 km HYDRA rocket shot at the Army's Yuma Proving Grounds in Arizona in October. BAE did the same with their system the following month, with a 5.5 km shot.

"The biggest technical challenge is the packaging. This is a 2.7 inch diameter shell, so we had to design the laser technology to fit," Frazier says. "We eventually will completely redo the rocket, but we're doing it in blocks. We first wanted to see if it was feasible to do something with the current rocket, which costs $1000-$1500, depending on the warhead, compared to $90,000-plus on a big missile. When you start going into a whole new development of a system, that drives cost very quickly. So we're taking the existing low-cost missile, making it accurate and keeping it low cost."

The Navy Advanced Gun System (AGS) will be looking first at LRLAP, being competed by SAIC and Raytheon, but the Navy reportedly also is considering variants of Excalibur and other medium range smart munitions.

Gun-hardened electronics

"There are applications for MEMS and nanotechnology across all smart munitions, but it is still not at an acceptable level across the gun-hardened electronics industry; it needs to be harder," says Steve Flach, director of munitions programs for United Defense Armament Systems Division in Minneapolis, Minn., which is under contract to Northrop Grumman Ship Systems on AGS design and development. "Right now we may be able to meet some lower range requirements, but that's not the goal. The goal is to meet those extended range requirements.

"Two things are important to future development: A projectile that can sustain the ranges and gun pressure of launch and electronics guidance packages that will put accuracy back into the system. Gun-hardened electronics may be the big challenge, but without a controlled flight projectile, you don't have what you need. You must have both."

United Defense also is working on a smart mortar system — a terminally guided hit-to-kill munition — that is a follow on to the precision-guided mortar munition (PGMM). The UDLP Armament Systems Division is working on that with Bofors Defence (also a UD division) and Saab.

"It will be programmable; the guidance and control mechanisms are currently being decided," Flach says. "We are now marketing a Bofors product — STRIX — that has been around about seven years that meets the Block 1 program threshold requirements and we believe with modest Block 1 modifications we can carry it through the objective system requirements."

Another smart program UD is demonstrating for the U.S. Army is BONU.S., a sensor-fuzed 155mm artillery shell developed by Bofors and Giat in France for use in 39 and 52 caliber guns. Similar to the now-shelved SADARM, but fin- rather than parachute-deployed, it carries two submunitions, each with multi-channel IR sensor, which are expelled and stabilized above the target. Commencing a search phase at an altitude of 175m, it strikes the located target with an explosively formed penetrator. Deliveries of BONU.S. to the Swedish and French armies began in 2002.

Flach says they are in the process of updating the seeker technology, but declined to disclose details.

Integrated fuzing

United Defense also is involved in development of the guidance integrated fuse (GIF), primarily as an add-on to the existing inventory of 155 shells. GIF is a 2-D corrector — range and bias — which officials say can produce better than a seven-fold improvement in effectiveness. To accomplish that, a nominal trajectory is computed and stored on the projectile, then an on-board GPS receiver establishes the shell's position, processors compute an actual trajectory, an end-point is predicted and compared to the aim-point and commands are sent to the maneuvering system to correct the trajectory accordingly.

"Those fuses are intended to be a recapitalization of the existing inventory of unguided shells, giving them the ability to perform in-flight corrections," Flach says. "Most of the designs are either inertial, GPS or a satellite uplink. The Navy is most interested for the 127 market, the Army for the 155 market. United is working on those. We have a contract for the NLOS-C (Non-Line-Of-Sight-Cannon, now called the Future Combat Systems Canon) and are competing for the LCCM contract."

As smart weapons proliferate, the computing needs involved are driven higher by the types of sensors — especially multiple sensors — being employed. However, there is a serendipitous element — the computing power needed to handle electro-optical, infrared, multimillimeter wave radar, ladar or a combination of those sensors are sufficiently high that a flight computer could be combined with the sensor processor, so one processor could control all weapon requirements — navigation, propulsion, guidance, sensors, communications, etc.

"We are being looked at for next generation weapons that need an increase in processing power over today's weapons set, which is not the same objective as retrofits," says Richard Jaenicke, director of product marketing for Mercury Computer Systems of Chelmsford, Mass. "These new weapons typically have multiple sensors and multiple targeting modes and options that are only selected at the last second and so need to have very capable processors and flexible processing in order to do that. The combination of PowerPC multiprocessors and FPGAs programmed with standard software is really the technology enabler.

"We believe it is so powerful and flexible our customers, for the first time, will be able to use one standard architecture across multiple types of munitions families. That is the core of the next generation of weapons. Right now, as you build one type of missile or another, it is a whole new design from scratch on a lot of the electronics. We do have some development contracts and are on captive flight tests on three different weapons systems, but we don't have our customers' permission to identify them."

Jaenicke says scaling systems down to fit into the tight confines of a missile, bomb, or artillery shell is not nearly as difficult as meeting the power requirements of a multi-sensor system. In some cases, battery power is conserved because not all sensors are operating throughout the flight, which also helps with heat dissipation. Using PowerPC processors, which are designed for the low power embedded processing realm, also helps, as does using integrated ASICs that combine a variety of functions onto one chip.

Circuit technology

"The vehicle for making a lot of this work is single crystal silicon, which most people are aware of because of its electronic properties. But it also has fantastic mechanical properties, which is what we are exploiting to make these very tough, robust parts," Foster says. "These are machines and we can shake and flex the silicon, billions and billions of times, yet we cannot measure any fatigue. If you stay below a fracture limit, there is no known fatigue mechanism in silicon. So these are machines that effectively last forever."

Exploiting that characteristic and incorporating the other technologies and techniques that make it all practical, he adds, is the key to making the kind of IMU the Army and the other services want.

"Transitioning into the smart realm is a key event for the Army and Navy. If you haven't got smart weapons, like the Air Force JDAM, you're sitting on the sidelines in modern combat," says Jim Grace, vice president-business development at Interstate Electronics Corp. in Anaheim, Calif., a division of L-3 Corp. "They are still shooting howitzer shells that take a lot of shots to take out a single target — and that is a logistics nightmare. The Navy is fine with its standoff missiles, but when you have to engage shore batteries or are trying to land Marines, they don't have the short-range weapons to support that. ERGM is an effort to regain the role previously played by the 16-inch guns of battleships, which have now all been retired, so that whole capability went away. The idea of ERGM is to resurrect that capability through a weapon that can be shot up to 60-plus miles against shore batteries that would be attacking our Marines as they land.

"They are trying to upgrade JDAM for longer range and anti-jam. All the weaponry is looking for enhanced SAASM (Selective Availability Anti-Spoofing Module) GPS technology. In the future, when the new satellite structure gets put up for GPS, the M-code (military code) will be even more jam-resistant. That's five or six years away. With respect to inertial, you'll see it get away from older fiber optic and ring laser technologies that can't reduce in size enough to get on these smaller weapons, which is bringing MEMS to the forefront."

But even MEMS is undergoing technology enhancements. Current MEMS IMUs can drift up to 100 degrees off target each hour, which is not a problem for ERGM or LRLAP, which are only in the air a few minutes, but for longer ranges that much drift would be disastrous. The government wants to get the MEMS IMU down to 1 degree per hour drift — equivalent to the ring laser and FOG (fiber optic guided) gyros — for the smaller long-range systems. However, achieving that level of accuracy requires a host of technology applications, from trimming the silicon to physics on the surface of a silicon substrate and what materials are added to it — all the intricacies of the lithography equipment that makes silicon chips.

"A MEMS IMU operates by measuring nanoscopic vibrations on a piece of silicon and the related changes of frequency. If you increase velocity by one mile per hour, how much deflection actually happens at the subatomic level and does it happen all the time. If the structure is bigger or smaller is it better or worse? As we make things smaller and smaller and smaller, the effects of physics are much more impacting on our ability to determine and control and measure the vibrations and changes in frequency," Grace says.

"As we integrate these technologies — smaller, lighter, cheaper — it becomes applicable to anything that moves, military or commercial, and must be reported to somebody to make a decision. That could be anything from a shell to a satellite to a truck. Everybody's desire is to have instant information about everything that impacts them and one key to that is sensors."

Jon Jones, vice president-strike weapons at Raytheon Missile Systems, agrees, adding the technology is especially valuable to increasing the utility — and lethality — of U.S. weapons.

Systems integration

"We're working mostly now on integrating the weapons to work better with the entire system — targeting, command and control, identification — and be responsive to central command authority," Jones says. "Specifically, that means we are pursuing greater precision with GPS-guided weapons and better immunity to jamming; there will be more focus on all-weather and 'GPS-the-night'. We have the ability to either retrofit existing inventory or build new weapons with this capability.

"We're looking at putting these capabilities in our Paveway (laser guided bomb) and JSOW (Joint Stand Off Weapon) lines and HARM (High-Speed Anti-Radiation Missile), which brings the high-speed for time-critical targets," Jones continues. "An example is where we recently used a special JSOW with a datalink in it to engage a moving target — a tank — and took guidance signals from Northrop Grumman's AMSTE (Affordable Moving Surface Target Engagement) system, a DARPA program. That was the first time a weapon like that has ever made a direct hit on a moving target. JSOW has no seeker for terminal guidance, using GPS to go to a known coordinate. AMSTE can track the target as it moves and provide upgrades via datalink to the weapon."

null

All this does not mean the end is in sight for "dumb bullets", however, because volume of fire — "steel rain" — remains an important option, as well.

"We still have a need for mass and volume in fire support engagements. There is a place for those on the battlefield because you still have to suppress the enemy on occasion, especially to protect maneuvering forces," Sledge says, adding there are some senior military leaders who believe all weapons in the future will have some precision enhancement and nothing will be shot ballistically.

"We may eventually get to that because if you don't have to shoot dumb weapons, you won't because they are subject to so many variables, from muzzle velocity to wind speed and altitude. But it's a matter of how much money we want to spend and how fast we want to get there. Today, the dumb bullet is still king."

Nonetheless, he acknowledges, a weapon such as Excalibur might have changed the outcome for U.S. forces pinned down in Somalia a few years ago. For the future, Excalibur will play a key role in the Future Combat System arsenal that will support the Army's Objective Force.

"It isn't so much the old missions have gone away as that new missions have been added," notes Abraham Shrekenhamer, chief engineer for smart weapons at Northrop Grumman Electronic Systems Sector in Azusa, Calif. "The Army vision for Future Combat Systems envisions U.S. forces deploying rapidly all over the globe without taking a lot of cargo. So munitions need to be more and more precise so you don't have to carry as many.

"Another requirement that did not exist too long ago is we are expecting more and more combat in urban environments. That also means using smaller weapons to minimize collateral damage and weapons with directional lethality, so you can have a more precise strike at targets dispersed within a civilian population."

Surveillance and weapons

That also entails a merger of surveillance and munition systems into a global continuum of operations, he says, with more expensive, but reusable, surveillance systems identifying, targeting, tracking, and pinpointing targets while the less expensive, expendable munition is in flight.

null

"The goal is to get more and more multipurpose munitions. Therefore, multimode sensors or algorithms that can adapt to different scenarios on an hour-to-hour basis will evolve so the same munitions can be used against bunkers, personnel in the open or even helicopters in flight," Shrekenhamer says. "Ways of employing warheads in different modes will get pushed along, along with sensors that can detect different kinds of targets. In the past, we chiefly employed radar and IR sensors; now we need to look more into laser radar and 3D imaging sensors."

Dr. Peter Plostins, Chief of the Aerodynamics Branch of the Army Research Laboratory at Aberdeen Proving Ground, Md., says some of those future technologies will comprise commercial-off-the-shelf components, while others will need specialized military development. How they are applied to weapons systems also will vary, driven by cost and application.

"In some instances, it is much easier for a specific mission task to take a dumb munition and modify it to have some capability," he says. "In other instances, because the mission requirements are such that a dumb munition can't satisfy it, there is no alternative but to come up with a new smart munition. You can give an artillery round some level of precision by modifying the fuse to read GPS."

Whether precision guided or smart by design or by modification, the goal of all these programs ultimately is to provide the tactical commander on the combined arms battlefield with the flexibility to bring optimum fire on his targets.

"Depending on the size of the tactical situation, he would prefer to have those assets available at all levels. He can't always get an air strike instantaneously, but he may be able to get artillery fire with smart munitions immediately available," Plostins says. "What you really want to do is provide a suite of munitions to the field commanders that allow them the optimum flexibility and decision authority to shape the battle to their benefit. Smart or precision munitions are part of that suite."