TRENDS

Change is coming quickly for military electronics designers

By John Keller, chief editor Military & Aerospace Electronics

Things have been relatively quiet lately in the military and aerospace electronics design community. For many of you I hope it has been a pleasant lull, because from all indications we stand on the precipice of several different fundamental changes that threaten to converge all at once.

First, and most obviously, as the new year dawns the United States finds itself in the midst of a full-scale war on terrorism, with major homeland security initiatives in progress domestically, and a pending invasion of Iraq overseas. While the war in Iraq promises to be short-lived, the homeland security war at home offers to last years — perhaps decades — perhaps even longer.

Nevertheless, from these domestic and international battles in the war on terrorism will shortly emerge some of military technology's most substantial lessons learned of the new millennium. U.S. capabilities and resources in the war on terrorism to date are largely untested, yet with the initial advances into Iraq we are about to get our first tastes of what works — and what doesn't.

In Iraq, U.S. warfighters plan quick strikes to undermine the regime of Saddam Hussein and rapidly occupy that country. Perhaps within weeks we will see how effective current U.S. strategy and weaponry are in conflicts of this kind. Mistakes in planning and execution undoubtedly will help military leaders fine-tune their technological approaches to the war on terrorism.

Several reports have it, for example, that U.S. military forces will unveil a new generation of smart munitions in the upcoming war in Iraq. Shortly, we'll see if the developers of these weapons are on the right track when it comes to taking on a wily adversary such as Hussein and the Al Qaida terror network. If developers are not on the right track, then the upcoming conflict should help them learn where they can make improvements.

On the domestic front, passenger and cargo screening at the nation's airports trucking depots, and maritime ports should push the limits of existing remote-sensing technology, and may spur new development of a few new technologies. Airport, harbor, and highway-transportation authorities are seeking new ways of "looking inside" shipping containers and passenger baggage to detect explosives and other illegal contraband without hobbling commerce. Not only will these needs nurture remote-sensing technology, but also will push innovation in systems integration to make the most of technology that is available off the shelf today.

Yet how effective the new approaches to cargo and baggage screening will be is still a question mark. Just as important as the technologies and systems integration also will be the ways in which authorities blend screening systems into the flow of passengers and freight. A noticeable slowdown in the movement of people and cargo will require rethinking the technology and its deployment. We should have a useful number of lessons learned within the next year — perhaps over the next several months.

Other changes in the works revolve around new generations of nanometer-scale electronics, where transistors on chips will be smaller than ever before. While this new breed of electronics components offers unparalleled benefits such as tiny size and weight, as well as broad new capabilities, they also threaten systems integrators with short obsolescence cycles, unforeseen challenges in testing, as well as new issues in how the new components stand up to demanding operating environments involving shock, vibration, heat, cold, and atmospheric radiation.

While semiconductor and systems-integration experts are coping with diminishing manufacturing sources (DMS) and the obsolescence problem, the new generation of nanometer-scale electronics confront designers with a whole new set of challenges that they have never dealt with before, warns Lloyd Condra, technical fellow at the Boeing Phantom Works in Seattle. Condra made his comments in December at the Military & Aerospace Electronics Show-West in San Diego.

"We cannot succeed or cope with tactics that we have used in the past," when it comes to aerospace electronic parts, Condra said at the conference. Among Condra's most pressing concerns about using commercial off-the-shelf nanometer-scale electronics in military and aerospace electronic systems are:

- short services lives of only three to 10 years in aerospace applications;

- possible non-constant failure rates and common-cause part failures;

- increased susceptibility to atmospheric radiation;

- uncontrolled device configuration changes; and

- inability of aerospace users to understand the impact of nanometer technology in applications other than the target market.

Some of the nastiest surprises of nanometer-scale electronics are yet to surface. To anticipate some of them, major system integrators are organizing the Aerospace Vehicle System Institute — better known as the AVSI — at Texas A&M University in College Station, Texas. Still, many unknowns loom for the industry, and designers will have to deal with many of these issues as they come up.

And this isn't all. Also on the horizon is a new generation of high-speed serial data interconnects, such as RapidIO, Infiniband, Star-Fabric, and 3GIO Express. No clear winner has emerged from the broad field of competitors, which will leave systems integrators officially supporting all of them to hedge their bets .

All in all, military and aerospace electronic systems designers have their work cut out for them in 2003, with far more questions than there are answers. I wish us all good luck.

TIBCO software reduced development time on NASA's X-38 project

by John McHale

HOUSTON — Officials at NASA's Johnson Space Center are using the Rendezvous development solution from TIBCO in Palo Alto, Calif., to improve research, development, and test processes for their X-38 ground communication system project.

The Rendezvous integration product was the final technology piece necessary for NASA's X-38 project ground communication system to provide command and telemetry interfaces to X-38 experimental vehicles, TIBCO officials say. The solution enables end users to perform NASA tests on experimental vehicles through the delivery of commands to the vehicle, receiving telemetry, processing data, and recording the results.

"Of the third party products we've used, TIBCO Rendezvous has been the smoothest integration we've completed," says Steve Rader, NASA X-38 ground systems development engineer. "TIBCO Rendezvous' real-time messaging ensures better service to X-38 ground systems control, as it has eliminated the enormous amount of workflow involved in making a display and has functionally grouped software to eliminate redundancy across the network. The flexibility of design, open API architecture, and decentralized server will easily and efficiently enable us to modify and add functionality to the system, as we grow and expand the project."

The operation is part of NASA's Aerospace Technology Enterprise, which has a mission to pioneer the identification, development, verification, transfer, application, and commercialization of high payoff aeronautics and space transportation technologies.

TIBCO Rendezvous' ease of add-on and multi-use capabilities, increased flexibility and decentralized server helps ground systems control reduce time for end users viewing interface display, access data in real time, enhance time in development, and most importantly, demonstrate a concrete cost savings equivalent to five to six developers, TIBCO officials say.

NASA's X-38 project is developing a prototype for a rescue vehicle that will provide astronauts on the International Space Station an immediate return trip home in case of an emergency. The vehicle will become the first new human spacecraft to travel to and from orbit in the past two decades. It serves as an ambulance for medical emergencies and as an evacuation vehicle.

This spacecraft was developed at a fraction of the cost of past human space vehicles, TIBCO officials say. Reduced development cost and an accelerated schedule were required to make the project attractive within current NASA budgetary constraints.

The X-38 Project has several flight test vehicles and a large group of end users — subsystem engineers, operations, and software developers. NASA X-38 project engineers needed a solution that enabled operation of NASA tests with experimental vehicles using a ground communication system that provided command and telemetry interfaces to vehicles in order to save time and money, TIBCO officials say. This was required so that end-users could deliver commands to the vehicle, receive telemetry, process data, and record the results.

X-38 project engineers faced designing or implementing a ground control system that would integrate the constant flow of new content and services into its messaging infrastructure without overhauling existing software code, TIBCO officials say. Design engineers also needed a solution that would not only aggregate content from several applications and operating systems, but also normalize it and distribute it to each relevant experimental vehicle within the project, company officials say.

At the time, NASA's messaging system was functioning under its own protocol, based on a User Datagram Protocol (UDP), TIBCO officials say. However, the system was not reliable or very flexible, company officials claim. As requirements grew and more vehicles were to be added to the project, a protocol was necessary to scale higher than what was originally built. The old system did not handle redundancy or several issues surrounding fault tolerance, TIBCO officials explain.

NASA's research and evaluation process reviewed UDP broadcast and other multicast solutions, as well as an in-house product — an ISP using TCP/IP. Researchers also considered writing their own solution, company officials say.

They settled on the TIBCO Rendezvous solution because it addressed a lot of things "under the cover," had the capability to build on top of it and scale for future requirements, TIBCO officials say. The solution also had multicast protocols, no centralized server, ease of add-on, multi-use, and increased flexibility, company officials say.

TIBCO Rendezvous enabled NASA engineers to integrate legacy and new applications with their messaging infrastructure without changing existing software code, TIBCO officials say. TIBCO's software integrates information across several applications and operating systems by providing a single flow of data that is automatically directed to each relevant area of the project.

TIBCO Rendezvous enabled NASA ground control system to go live with its first X-38 experimental vehicle within four weeks of implementation, company officials say.

The X-38 project's implementation of TIBCO Rendezvous is being used by several levels of management as a test bed for the latest and greatest in ground system control messaging infrastructure, TIBCO officials say. There are several technologies that are being developed that have already spun off into other divisions (military, commercial), company officials say.

For more information on TIBCO contact the company by phone at 650-846-1000, by fax at 650-846-1005, by mail at 3165 Porter Drive, Palo Alto Calif. 94304, or on the World Wide Web at http://www.tibco.com.

null

ManTech uses Synergy board for Vivid Pointer radar processing system

by John McHale

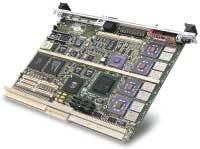

SARASOTA, Fla. — Engineers at ManTech Real-Time Systems Laboratory (MRSL) needed a single-board computer that could run Linux for their Vivid Pointer Combat Identification System. They found their answer with the model VSS4 quad DSP (digital signal processor) board from Synergy Microsystems in San Diego.

The Vivid Pointer system has been successfully demonstrated to the U.S. Air Force, and is now active for future fielding, says Dave Klueck, marketing manager, technical communications at Synergy. MRSL has prototyped a version of the Vivid Pointer system customized to fit a dual-CPU package.

The MRSL's system augments fielded Radar Warning Receivers (RWR) and Electronic Warfare (EW) systems with advanced time-frequency algorithms and decision logic to detect and identify Pulse Doppler (PD) radar signals, Klueck says. It provides a cost-effective solution to modernize these systems to meet the existing PD threat, he adds.

With steady advancements in radar signal processing, PD has gradually become standard equipment in most of the world's combat aircraft and surface-to-air missile (SAM) systems, Klueck says. However, the current generation of RWR and other EW systems has only limited capabilities to identify the source of these PD signals. In some cases, they may be unable to distinguish between enemy and friendly aircraft and thus can jeopardize a pilot's life, company officials say.

The need for unambiguous identification has assumed a special urgency, as many recent missions involve NATO or other multinational coalition forces operating in an electromagnetically dense battlespace, Klueck says. The probability of fratricide could be unacceptably high if allied aircraft are unable to identify PD signals, company officials say.

This type of radar detection requires extensive signal processing capability, which is why MRSL officials chose the Synergy board, which uses G4 PowerPC CPUs with AltiVec processors that execute as many as five floating-point instructions per clock cycle, Synergy officials say.

The Synergy Scientific Subroutine Library (SSSL) also made it very easy for MRSL developers to use the VSS4's advanced DSP functionality, company officials say. The SSSL saved the program the time and cost of optimizing low-level code with its hand-coded, double-precision routines, Klueck says.

The immediate availability of Linux with symmetric multiprocessing (SMP) was also an important factor, Synergy officials say. Some SBC vendors simply could not support SMP Linux and others could not make good on their promises to have an implementation working in time, Klueck says.

Open source Linux also improved the life cycle cost of the product compared to proprietary solutions, he says. New projects begin without the burden of licensing agreements and during development Linux provides a wealth of ready-to-use drivers, debuggers, and other tools, Klueck explains. "Its huge, well-established user community also ensures readily available resources and expertise for years to come," he says.

Using Linux on the VSS4 board, MRSL programmers were able to abstract the Vivid Pointer algorithms away from the supporting hardware, creating hardware independence, Klueck says. "Early on, MRSL had employed technology that featured complex arrays of DSPs, each handling a dedicated portion of an algorithm in series. A failure on any individual device forced a long search through the array to locate and correct the fault. This platform left the application closely tied to proprietary hardware."

Using SMP, all the processors in the system share a common operating system and global memory, which helped obtain the MSRL's cost containment and portability goals, Synergy officials say. "SMP strives to distribute the load among the processors in balanced proportions, hence the term symmetric," Klueck says.

SMP Linux also brings cost savings to soft real-time DSP applications, by eliminating the per-processor licensing fees and the maintenance burden associated with expensive proprietary operating systems. SMP frees up software development resources, keeps programmers focused on important application algorithms, and generally saves the project a significant amount of expensive software development time, Synergy officials claim.

MRSL engineers developed their software code on the same VSS4 hardware that will be inserted into aircraft avionics systems, Klueck says. They used the on-board Ethernet to connect the application to the desktop workstations of the whole development team. "Using a competitor's SBC would have required MRSL to customize the Ethernet communication functions on PMC sites," Klueck says.

For more information on Synergy Microsystems contact the company by phone at 858-452-0020, by fax at 858-452-0060, or on the World Wide Web at http://www.synergymicro.com.

U.S. Air Force uses Cherry smart card to secure computer systems

by John McHale

PLANO, Texas. —Officials at EDS in are using smart card readers from Cherry Electrical Products in Pleasant Prairie, Wis., to help secure thousands of computer systems at more than 100 U.S. Air Force sites worldwide.

Cherry will serve as the Air Force's sole provider of stand-alone smart card readers for the service-wide implementation of a U.S. Department of Defense (DOD) smart card initiative. Cherry officials will supply stand-alone smart card readers — Cherry's ST-1000 — to help add a new layer of security for more than 50,000 computer users, Cherry officials say.

Officials of the Air Force as well as the DOD are enhancing their access security posture through the use of the DOD Common Access Card (CAC) smart card technology, Cherry officials say. The DOD is scheduled to issue 4 million CAC cards during the next two years. The CAC is the only smart card on the market that meets the DOD CAC specifications for Java-based smart cards with cryptographic applications, company officials claim.

Middleware and Cherry stand-alone smart card readers provide the interface technology from the smart card to the computer, Cherry officials say. Service members use a smart card to verify their identification, for secure access to computer systems, and to digitally encrypt and sign email, company officials say. EDS officials began delivering 600,000 of smart cards to active duty personnel, reservists, and National Guard members last year. DOD officials left the responsibility of integration and implementation of the cards to each branch of the U.S. Armed Forces, Cherry officials say. The smart cards are also used to allow access to DOD facilities.

"The smart card readers and middleware will certainly enhance DOD security and could playa significant role in the future of national identification cards," says Phillip Kirsch, government sales manager at Cherry.

Cherry Corp manufactures proprietary and custom electrical switches, sensors, electronic keyboards, and controls for the automotive, computer, consumer, and commercial markets.

For more information on Cherry's smart card readers contact the company by phone at 800-510-1689, by fax at 262-942-6566, by mail at 11200 88 Ave., Pleasant Prairie, Wis. 53158, or on the World Wide Web at http://www.cherrycorp.com.

null