Northrop Grumman delivers second laser for airborne missile defense

By Ben Ames

REDONDO BEACH, Calif. — The U.S. Missile Defense Agency's Airborne Laser (ABL) program drew one step closer to its goal Feb. 26 when Northrop Grumman delivered the Beacon Illuminator Laser (BILL) to Lockheed Martin's Sunnyvale, Calif. facility. When complete, the ABL will try to knock incoming missiles from the sky with a powerful laser blast.

In turn, Lockheed Martin engineers will integrate the BILL into their beam control/fire control system, then deliver the entire package to Edwards Air Force Base, Calif., where experts will install it aboard a modified Boeing 747-400F jumbo jet.

In the finished system, the 747 pilot will patrol the skies, seeking missiles. When his crew finds a target, they will use the kilowatt-class BILL to illuminate a small spot on the missile. The reflected energy will measure atmospheric turbulence that could degrade the beam quality of the megawatt-class "kill laser." Then they will use a deformable mirror to fine-tune the main beam before firing on the target.

null

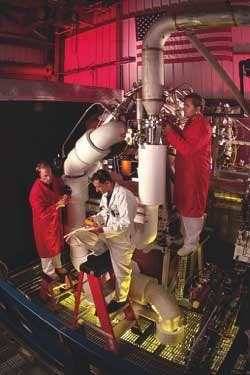

Loading such powerful lasers on an airplane was a tough engineering challenge, says Steve Hixson, airborne laser program manager at Northrop Grumman Space Technology (formerly TRW), in Redondo Beach, Calif. They had to be lightweight enough to fly, yet strong enough to withstand the vibration and dynamic G-force loading of an airplane.

Northrop Grumman engineers used two technologies to do it. The BILL is a diode-pumped slab laser design, as opposed to typical flash lamp pumping, Hixson says. That lets engineers pump the neodymium-YAG laser crystal with less heat dissipation, so they can push it much harder with fracturing.

Second, the BILL uses a master oscillator power amplifier design, which applies three amplifiers and stimulated Brillioun scattering (SBS) to focus the beam into a liquid cell, so the phase conjugate produces excellent beam quality, Northrop Grumman officials say.

"Together, those two unique features enable both high power and high beam quality," he says. They correct phase distortion with adaptive optics to provide the best possible focus for the chemical oxygen-iodine laser (COIL) killer laser beam.

"It was a design challenge, because we had to produce something you'd want to make big and heavy to shield the laser, to control stray radiation and beam. And yet there's a countervailing requirement to make it lightweight," Hixson says.

When the laser fires, it focuses a "basketball-sized spot of heat that can burn through a missile skin from hundreds of miles away," the Northrop Grumman officials say. More details on the system are on the World Wide Web at http://www. airbornelaser.com/.

The BILL produces one beam from two LRUs (line replaceable units). "They interweave," Hixson says. "One fires, then the other, like a Gatling gun."

Managing the Airborne Laser program are officials of the Air Force ABL system program office at Kirtland Air Force Base, N.M., which reports to Aeronautical Systems Center, Wright-Patterson Air Force Base, Ohio. The Department of Defense Missile Defense Agency (MDA) has management authority and funding responsibility for the ABL program. For the latest news on the ABL program, check www.acq.osd.mil/bmdo.