By John McHale

WASHINGTON - Automation experts from industry and academia are teaming to build a robot that can help detect, locate, and destroy snipers or enemy mortar crews. The project was unveiled at the Association of the U.S. Army’s (AUSA) Annual Meeting last October in Washington.

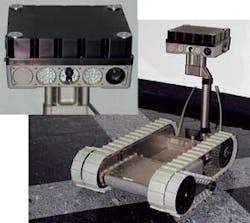

Officials at iRobot Corp. of Burlington, Mass., and the Photonics Center at Boston University in Boston introduced a tactical sensory-system payload prototype, dubbed REDOWL, at AUSA REDOWL, or Robot Enhanced Detection Outpost with Lasers, can detect and locate snipers and mortars on the very first shot fired at personnel or vehicles. It will sense the sniper, acquire the target, and give range so the sniper threat can be eliminated, says Dr. Glenn Thoren, of the Photonics Center and director of Project REDOWL.

AUSA demonstrated the REDOWL robot as it immediately turned toward the sound of a simulated gunshot in much the way a hunting dog reacts and points when he senses his prey.

REDOWL is a rapid-development program led by the Photonics Center at Boston University with iRobot, Insight Technology in Londonderry, N.H., and BioMimetic Systems. The Army Research Laboratory in Adelphi, Md., is the primary source of funding for the project.

The system is a remote, deployable sensor suite designed to provide early warning information, gunshot detection, intelligence, surveillance, and targeting capabilities to military forces and government agencies. It also is for homeland security applications and border control, says Tom Ryden, director of sales and marketing for government and industrial robotics at iRobot.

“Snipers have had the advantage of being effectively invisible, making them a deadly threat on the battlefield and in urban settings,” says retired U.S. Navy Vice Adm. Joe Dyer, executive vice president and general manager of the iRobot Government & Industrial Robots. “REDOWL is a mobile system, which means snipers can run but they cannot hide anymore.”

The REDOWL-equipped PackBot has been field-tested for the Army’s Rapid Equipping Force at a rifle and trapshooting range. The REDOWL system located the source of gunfire 94 percent of the time out of more than 150 rounds fired from 9mm pistols, M-16, and AK-47 rifles from farther away than 100 meters.

The iRobot PackBot can be hand-carried and deployed by one soldier. Deployed in Afghanistan and Iraq, PackBot searches dangerous or inaccessible areas, providing a safe first look so soldiers know what to expect and how to respond.

“REDOWL more than satisfies mission requirements to provide advanced optical and acoustic detection capabilities to the U.S. military for use in its growing inventory of unmanned ground vehicles,” Thoren says. “Combining optics and acoustics systems together with iRobot’s PackBot to detect and locate a source of hostile fire or track moving vehicles, day or night, is a first in systems integration for unmanned vehicles.”

REDOWL-weighing 5.5 pounds-features optical and acoustic detection systems including a laser pointer and illuminator, acoustic localizer and classifier, thermal imager, GPS positioning, an infrared and daylight camera, and two wide-angle cameras, Thoren says.

When integrated with the PackBot, these systems enable the robot to detect, locate, and identify the origin of hostile gunfire. These systems also help REDOWL do day and night urban surveillance, reconnaissance, forward observation outposting, perimeter protection, and deal with hostage/barricade situations.

REDOWL features an acoustic direction finding (ADF) system developed by BioMimetic Systems, Thoren says. The ADF is based on advanced “neural circuits” emulating human hearing and provides accurate detection and bearing information in high background noise.

Two microphones placed an inch apart simulate human hearing, Thoren says. BioMimetic engineers also added two more microphones for redundancy and enhanced accuracy.

In addition to providing its PackBot robot platform, iRobot developed the software and behaviors for the robot. Insight Technology, a manufacturer of visible and infrared laser and illuminator systems, is heading up the development of REDOWL’s optical systems.

Many of the optics have been available separately, but this is the first time they have been integrated together in the same system with acoustics, Thoren says. REDOWL works in daylight and has night-vision capability, he adds.

The Photonics Center at Boston University identifies and develops technologies based on the practical application of light, and hosts a business accelerator that enables emerging photonics technology companies to grow from idea to commercialization with greater speed and success.

The center provides an entrepreneurial environment that includes 21 laboratories, workspace for as many as 20 start-up companies, and access to a range of equipment worth in excess of $40 million. To date the Center has started and/or accelerated 18 companies that have raised a combined total of over $225 million in outside venture capital and seed financing.

BioMimetic Systems is one of those companies and has replicated the functions of the human ear with its acoustic sensor, which uses two or more microphones, Thoren says.

For more on the Photonics Center go to www.thephotonicscenter.com. For additional information about iRobot, visit www.irobot.com.