By Malcolm Baca

Technology advancements at the component level and changing marketing conditions reduce the effectiveness of our existing obsolescence methodology. Obsolescence information services, like components and materials, also have a lifecycle. Changing technology and marketing conditions can render them ineffective, too.

Our information requirements need to change for many reasons.

One problem is the continuing decline of the purchasing power of U.S. Department of Defense (DOD) for components. In response, experts are considering the consolidation of the technology baseline to reduce fragmented and redundant diminishing-manufacturing-source (DMS) platform management.

Another problem related to DOD’s weakening purchasing power is that fewer components are needed. In response, experts are making the transition to fewer platform-centric systems and more data-centric systems based on common problems.

Also plaguing DOD officials is the small job-shop suppliers to which many jobs are outsourced. These small shops simply lack or cannot afford obsolescence information services. In response, officials need to use information services that enable cost-effective teaming support across all team members working a common program.

In addition, officials find that existing program autonomy, while essential, contributes to redundant research and fragmented solution costs for obsolescence management at the component level. To deal with this, officials need a means of collaboration and solution sharing at component level that does not interfere with program decisions.

Finally, large new programs have the DMS tools that older or small programs cannot afford. What is needed is the centralization of DMS tooling and information access, leveling the playing field for all.

It’s easy to state problems and needed vision improvements, but how can these improvements be accomplished? Especially when today’s accumulative DOD technology footprint, representing 95 percent of all components used in military weapon-system applications, is expanding (see Figure 1). These trending conditions will reduce the effectiveness of traditional information services and current DMS methodology.

Fortunately, information-technology and software-application flexibility used to create data-centric information technology has improved substantially. This flexibility opens the door to rapid advancements in vision improvements.

Use of data-centric information services will make it possible to enter the “third dimension in obsolescence management,” which I define as anyone working a component-level problem who can instantly determine who else is working the identical component-level problem and through mutual consent move into a collaborative operational environment, including solution sharing for replacement options.

The new breeds of information services are Web-based applications built on the newer information technologies. They are easy to learn, use, implement, and maintain, and can be made compliant with International Traffic in Arms Regulations (ITAR) for data exchange.

As an industry, our challenge becomes: can we change our cultural practices to exploit the value proposition that the new information age can deliver?

How can defense and aerospace supply chains optimize their obsolescence organizational structures? How can they improve their effectiveness by using the information services that allow team collaborative environments across any entity working identical component problems?

For defense and aerospace suppliers who are able to make these adjustments, the benefits are impressive-improved customer satisfaction, improved competitiveness, and improved profits. Defense and aerospace program offices managing and using the equipment benefit from improved combat readiness, increased operational sustainment, and increased maintenance, repair, and operational (MRO) cost avoidance with verifiable savings.

We face this challenge at a time when every DOD program office and weapon-system supplier feels the impact of tightening operational budgets and pressure to reduce staffing requirements. The message is clear-we must do more, do it better, and do it with less.

This is the promise of shifting from platform obsolescence management to data-centric management on common component-level problems. This transition is what I call entering the third dimension of obsolescence management.

The third dimension

Data-centric management of component-level problems requires two major changes. One is technological-migrating to an obsolescence methodology that uses centralized, data-centric information services. The other change is cultural-enabling program structures to work common component-level problems, in a collaborative operational environment that allows solution sharing for replacement options on component-level problems.

The information technology is available now that can reduce redundant research on common problems and allow a collaborative operational environment, as well as eliminate each box-level program team from having to shoulder the entire solution costs on common component-level problems.

The improvements in methodology and obsolescence information services over the past 20 years are truly remarkable. Unfortunately, we still cling to our cultural disciplines structured and focused on managing specific weapon-system platforms. Yes, we must maintain the autonomy of our program-office structures, but we must also automate our ability to reduce redundant tasking when working common component-level problems.

Currently, obsolescence information services focus on two critical dimensions of information support at the platform level. One dimension is the use of pro-active component lifecycle projections during component selection for a new design or sustainment of an existing design. The second dimension is early warning that component availability has changed and linking that notification to system usage. These two dimensions of information needs are basic to optimizing cost avoidance on a specific program or platform.

The third dimension is the seamless interoperability on common component-level problems. Two requirements must be in place to achieve this goal. One, there must be wide-scale usage (being as user-friendly as the Internet is a good litmus test). Second, there must be data-centric visibility on common component-level problems that allows seamless collaboration or solution sharing on common problems.

The inherent weakness of today’s obsolescence information services is their inability to provide access and usability to the entire program team. Their technology, complexity, and lack of user friendliness prohibit widespread use.

If only two or three individuals are capable of using the existing information service, then the information age’s promise of empowerment is empty. Think of it as a blocked organizational artery that forces large-scale information to flow, and access, through a funnel point of two or three individuals.

This kind of a restriction is archaic and outdated to supply-chain process flows. Information empowerment should be as available as the ubiquitous PC. To achieve the highest level of obsolescence management excellence in “response time” and “cost savings potential,” you need a common obsolescence process flow directly available to the entire supply chain.

Why? Because obsolescence information needs vary across the supply chain. Information needs may involve the design engineer doing component selection, the component engineer solving obsolescence problems on production or legacy systems, procurement experts wanting to know the availability issues, program management wanting to know the obsolescence vulnerability for their program, or logistical support plans for operational sustainment.

Obsolescence management systems must be directly accessible by all and flexible enough to meet varying information requirements.

An example of centralized information support that provides three-dimensional information services is the DOD DMSMS Center of Excellence (COE). The Web page for this organization is at www.dmsms.org.

Defense Transformation in DOD is rapidly moving toward the third dimension by centralizing obsolescence information services and working toward providing a seamless portal that allows users to have the flexibility to use the COE for an application-specific requirement based on the individual’s need.

Today’s advancements in software and a data-centric information technology allow development of the third dimension that has been lacking in obsolescence management.

The new dimension will enable common component visibility across any defined entity that wants to participate in working common component-level problems. The COE organizational structure for information services is a developing example of raising the bar of excellence in improving obsolescence management efficiency and optimizing cost avoidance.

One of the many objectives is to provide a centralized one-stop shop with open access to all DOD agencies. Thus the COE offers training, case studies, newsletters, and is transitioning to bring seamless access to multiple research libraries and a full array of analysis tools to determine obsolescence vulnerability.

One of the many examples of the COE’s three-dimensional capability is QinetiQ’s Q-Star obsolescence and lifecycle information service that provides data-centric information to determine commonality and assess the lifecycle risk impact. Q-Star enables all user participants to enter a collaborative, operational environment on common component-level problems. Q-Star makes it possible to share obsolescence solutions under secured conditions.

By providing several facets and different tools for obsolescence, COE offers users an option to participate in the three critical dimensions of obsolescence service: using component lifecycle projections for component selection or forecasting DMS, early warning and timely discontinuance notification through a combination of services linked to system usage, and providing visibility across all participating programs affected by a common component problem.

All this with an automated means to enter the collaborative environment, work common problems, and share solution replacement options at the component level.

Through the COE’s centralization they are in a position to provide a range of information services that are necessary to manage the many facets of obsolescence. Any sector of the supply chain can tailor their searches to the specific information services they need in their specific area of responsibility.

No one wants to pan a ton of sand to get that golden nugget of information. Nor can many program offices afford the full array of information tools that are currently available at the COE.

For DOD to be cost-effective any facet of obsolescence management information should be no farther away than a few clicks of the mouse. It should provide seamless services that include access to multiple information resources, program analysis, alert notifications, with alerts linked to usage, replacement options, lifecycle projections, commonality of usage, and collaborative operational environments on common component-level problems.

With the newer generations of data-centric technology being developed or currently available from the COE, users will be able to navigate an array of various information resources in a seamless process flow.

This COE capability is no more difficult to use than the Internet. Any DOD or USG agency can participate in the interoperability environment, under secured conditions, on common component-level problems, at the component level. This is the capability that enables solution sharing at the component level . . . it’s the missing “third dimension in obsolescence management.”

By using centralized, data-centric, information technology, obsolescence management can automatically shift from platform-centric obsolescence management to data-centric management on common component-level problems-under secured conditions with each program office maintaining control of its obsolescence-solution process.

With the data-centric system security, it is impossible for any participants to view another’s part usage or configuration. Using Q-Star as an example of security within the COE, the commonality information provided by Q-Star is restricted to the component manufacturer’s part number, point of contact, phone number, and the e-mail addresses of those participants who share the common problem.

Data exchanges are compliant with ITAR. Information about the configuration, where used, how used, how many used, under what conditions used, and the weapons-system identifications are restricted, secure, and confidential.

Data-centric parts management opens new opportunities for cost avoidance and brings about an equalization of value to all participants. The playing field is level for all participants who want to work common problems and each program office is free to do what is best for its respective program.

What are the benefits of three-dimensional obsolescence management at the component level? To name a few:

- Someone working a component problem can instantly determine who else is working the identical issue

- It provides access to a collaborative operational environment for common problems

- It provides time to assess bridge-buy quantities by DSCC for participating DOD programs and provides the individual program more time to determine a long-term solution

- It provides the opportunity to consolidate fragmented procurements and reduce fragmented purchases that carry a higher unit cost;

- It levels the playing field for all programs, large or small, to optimize cost avoidance on common component problems

- It enables a faster reaction time that increases the time available to take advantage of low-cost solutions while such options exist

- By enabling a collective negotiation, it increases the leverage on the original component supplier to make one last production run

- It reduces repetitive tasking and minimizes redundant research across the many programs affected by a common component problem

- It provides the opportunity for wide-scale international interoperability with allied forces and weapon system suppliers on common component-level problems

- Data-centric summarizations provide a tool to encourage the development of aftermarket sources, or better enable emulation efforts or reverse engineering to prolong continued component support

- It provides DOD a means to improve the technology baseline management across all land, sea and air weapon systems

Three-dimensional obsolescence management can benefit all participants. Team collaboration with its resultant cost avoidance, improved reaction time, and reduced redundant research will consistently exceed that of any individual effort working the same component problem. Program teams, engineering services, or corporate entities that are willing to benchmark these concepts will have a distinct advantage in mitigating the financial exposure component obsolescence presents.

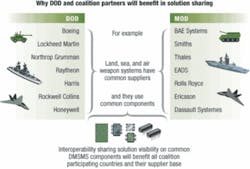

Even international doors to interoperability at the component level are being explored (see Figure 2). The COE plans to expand its DOD interoperability capability by inviting coalition-friendly countries and weapon-system suppliers to participate. For example, the United Kingdom’s Ministry of Defence is working with the COE to provide a means for international interoperability on common obsolescence problems under secured conditions.

The ultimate objective in providing obsolescence solutions is to partner for total warfighter support. The third dimension in obsolescence management uses data-centric information services, to work common obsolescence problems, in a teaming effort. As our future becomes a reality, those programs that evolve to embrace this new dimension ensure their leadership.

Malcolm Baca is president and chief executive officer of QinetiQ Technology Extension Corp. (QTEC) USA in Norco, Calif. Prior to QinetiQ Mr. Baca was the founder and chief operating officer of TACTech Inc. a company that commercially pioneered the development of global daily updated semiconductor availability libraries and also supplied dedicated software to manage semiconductor obsolescence. Baca is an expert in developing advanced information support systems that track component availability for active and passive devices. For more information contact the company by phone at 949-376-5757, or online at www.qtec.us/menu/QTEC.htm.