Never-ending demands for more electronic and electro-optic systems capability mean military and aerospace systems guzzle more electric power, and that means steadily increasing heat that engineers must get rid of-somehow. Today’s choices include convection-, conduction-, and liquid-cooling options, and tomorrow’s choices will be more complex.

By John Keller

The ability to cool ever-more-powerful electronics and electro-optics in military and aerospace systems may be one of the central design issues of our time.

It was not long ago when systems engineers with relative ease could remove heat from their devices with conduction or forced-air convection cooling. Today, however, the never-ending quest for increased performance is pushing power levels of air-transport-rack (ATR) electronics enclosures to exceed 100 watts per slot, as high-performance VXS, VPX, and VPX REDI circuit boards enter the scene.

“We are on a continuous ramp-up of watts per slot,” says Jim Tierney, vice president of government systems at Carlo Gavazzi Computing Solutions in Brockton, Mass. “General-purpose processing, DSP, imaging-all that technology-is being pushed into smaller form factors and condensing the heat. We are pushed to the limit of heat in our boxes. All systems are pushing the envelope.”

Conduction cooling, as its name suggests, wicks heat away from circuit-board sidewalls, and then away through the chassis where the heat dissipates into the surrounding air. Forced-air convection cooling most often moves relatively cool fan-flown air through the chassis directly over hot components such as power supplies and microprocessors to convey the heat through vents to the outside the enclosure.

In the recent past, conduction and convection cooling techniques were more than sufficient. Today, however, they are starting to present systems designers with difficult and sometimes complex challenges.

“Go back five years, and we had a few customers who had 100-watt VME-size boards; those were the leading-edge applications,” says Robert Sullivan, chief technology officer at Hybricon Corp. in Ayer, Mass. “Now your everyday VXS and VPX board out there is 100 watts or more, and the hot ones are pushing 200 watts.”

The reason for the increasing power is the insatiable appetite for improved system performance in processor speed, graphics processing, communications bandwidth, signal processing, and more.

“Moore’s Law says you will double the processor power ever 18 months, but the thermal loads have been going up in parallel with that,” explains Jim Shaw, vice president of engineering and operations at rugged computer manufacturer Crystal Group Inc. in Hiawatha, Iowa. “It becomes more and more of a problem; as we get more capable electronics, they require more power.”

In facing these new challenges, systems designers have a variety of options-not all of them attractive. When designers reach the limits of conduction cooling, they either can combine air and conduction cooling, or they can look at larger, more complex, and more expensive alternatives involving a variety of liquid-cooling approaches.

Liquids, after all, are far better than air at removing heat. Water, for example, is 1,000 times denser than air, has 35 times the thermal conductivity, offers four times the heat capacity per pound, and can be quieter than forced air.

Despite its obvious advantages, liquid cooling approaches typically are larger, heavier, more complex, and more expensive than conduction or convection cooling. Historically, liquid cooling also has experienced reliability problems because of leaks induced by physical stresses.

“Liquid cooling is relatively expensive and has a limited application,” Shaw says. “The heat exchanger required for the transfer of energy from processor to ambient air takes a large amount of volume. Sometimes it works where you can put the heat exchanger outside a vehicle and blow the heat outside, but where you are fairly constrained in an avionics or ground-mobile environment where you are fairly tight in space, sometimes it just doesn’t make sense.”

Crystal engineers have experimented with liquid-cooling approaches such as liquid-flow-through cooling and liquid spray cooling, and have found it to be very effective, Shaw admits. “If you have space, and cost is no object, liquid cooling is a winner,” he says. If not, however, designers have to look for other options.

Many of today’s military and aerospace applications, for example, involve systems upgrades, technology insertion, and technology refresh, where moving from air or conduction cooling to liquid cooling simply is not an option.

Today, perhaps more than at any other time, the ability to design systems with innovate ways of dealing with heat, is a crucial consideration. “People need to pay more attention to thermal engineering, and this is very important moving forward, warns Hybricon’s Sullivan.

Conduction cooling

One of the most popular ways of cooling embedded electronics in military and aerospace applications is conduction cooling-or removing heat from the sides of printed circuit cards and channeling the heat outside the enclosure either to heat exchangers or simply to dissipate in the ambient air.

Conduction cooling has been the predominant choice among these kinds of designers systems because it is relatively simple, inexpensive, inherently rugged, and, for the most, part effective. A particular advantage of conduction cooling involves its sealed electronics enclosures. This approach protects sensitive electronics from contaminants such as dust, moisture, and salt spray. Conformal coating of circuit boards often is unnecessary since enclosures are sealed.

The problem with conduction cooling these days, experts say, is it is falling short in its ability to cool advanced-technology circuit cards generating in excess of 100 watts. These conditions are compelling designers to sharpen their pencils to figure out the best ways to eke out the maximum benefits of conduction cooling before considering other options. Other applications simply may move on to something else.

“Conduction cooling, as we’ve always known it, is starting to drop down to the 3U form factors in VXS,” as increasing numbers of high-power circuit boards enter the market, says Carlo Gavazzi’s Tierney. “I see conduction cooling falling out of the 6U form factor and down into the 3U form factor.”

Crystal Group specializes in rugged computer servers for deployed military, aerospace, and homeland-security applications, so getting everything they can out of conduction cooling is essential to keep their production costs under control.

One of the first things Crystal Group designers did was add metal-machining capability to their Hiawatha, Iowa, manufacturing facility, and change chassis materials from cold-rolled steel to aircraft aluminum, Shaw says. Aluminum, he says, is “very strong and very thermally conductive. We build the chassis entirely out of that material and conduct heat from the bottom side of the processor directly to the bottom of the chassis, so you remove heat conductively from the bottom and blow it off from the top.”

Finding innovative new ways to cool electronics conductively also could help Crystal Group and other technology companies save money by pushing the limits in which they can safely use commercial off-the-shelf (COTS) computers and components. “It gives us more headroom to take a COTS processing element or board and put it into a military environment,” Shaw says.

Of related importance is the steady demand for upgrades to military equipment ranging from aircraft, land vehicles, ships, submarines, communications systems, and others. Many of these systems needing upgrades have no option other than the kind of cooling systems with which they were originally designed, due to size and weight considerations. Legacy conduction-cooled systems, to receive upgrades with the latest technologies, often need to stay with conduction cooling.

“A lot of programs are technology insertion and technology upgrades to existing platforms, and most of those platforms don’t have liquid cooling,” says Hybricon’s Sullivan. “If the platform doesn’t have liquid, you back into other solutions.”

Air cooling

Plenty of military and aerospace applications also use forced-air convection cooling, particularly when there is a low possibility of contaminating components with dust and dirt. “We have two systems we use: in the first we can conformally coat the circuit boards to seal them from dust contaminants and from moisture,” says Crystal’s Shaw. “We use an acrylic coating to put on to protect the boards, which works in a limited application where you don’t have a lot of salt fog or dust.”

Often the task of improving conventional air cooling to accommodate modern generations of high-power electronics is a matter of making small improvements here and there to keep electronic components within their thermal limits.

“We are trying to tweak our air cooling, because once you move away from air cooling, your costs increase,” says Carlo Gavazzi’s Tierney. “Everyone is trying to get the most out of the current technology, because to move is a quantum leap.”

Improvements in air-cooled electronics “is all tweaks-taking two percent here and two percent there,” Tierney says. “There are no quantum leaps in air cooling. That’s our challenge. We need to have a good understanding of the deployed environment.”

Engineers at Crystal Group also struggle to push air cooling as far as possible. “There are things you can do to improve air flow and cooling,” says Crystal’s Shaw. “How much mass-flow do you get, and how much pressure drop can you tolerate? You need to keep cables tied down and optimize air flow-and you have to think about it up front.”

Crystal Group engineers also have found ways to use air cooling in air-contaminated environments that might otherwise rely solely on conduction cooling. “One way is the air flow from the rest of the electronics,” Shaw says. “You can put very-high-flow fans and their vane axial fans into a tube attached to the processors, and that fan doesn’t blow air over the rest of the circuit board.”

Blending air and conduction cooling

Tracewell Systems of Westerville, Ohio, an innovative designer of air-cooled electronics, counts embedded-electronics standout Mercury Computer Systems of Chelmsford, Mass., among its clients.

Tracewell specializes in blending air and conduction cooling for advanced-technology circuit boards that generate more than 100 watts. “There is a real problem in getting these rugged cards deployed and cooled,” says Matt Tracewell, executive vice president of Tracewell Systems. “The debates are that they would not be usable in air environments.”

To that claim, Tracewell and his engineers say they have a solution. “We have an approach in which you can put these VPX 240-watt cards, put into ATR-style box, and cool them with air,” Tracewell says.

The company’s approach starts with a sealed conduction-cooled box that channels air off the card sidewalls and onto “cold walls” lining the sides of the box.

“We went back, did a lot of basic research, and asked what are the physics of why you can’t remove all this heat,” Tracewell explains. Others had concluded that air and conduction cooling could remove heat only from enclosures generating 80 or 90 total watts of power. After that, they decided, only some form of liquid cooling would do.

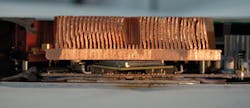

“Liquid through the box is far beyond the ability of air to remove heat,” Tracewell admits. “But what if there is no liquid?” Instead, Tracewell engineers fit large heat sinks on the sides of their enclosures and blow air over the heat sinks to get rid of heat removed conductively from inside the box.

“I pull air through the sidewalls of the box, while the inside of the box is sealed up,” Tracewell explains. Instead of braised fins on the sides, we have a different heat-spreading and -dissipating structure that is so efficient that we can take a 90-watt limit up to the multi-hundred-watt range.”

Tracewell says his company’s approach, which cools the Mercury Computer PowerStream 6600 embedded computer system, could provide sufficient cooling for an enclosure generating close to 250 watts of heat, if taken to its outer limits.

Likewise, engineers at Hybricon also are using air cooling-and sometimes even liquid cooling-to increase the efficiencies of conduction-cooled chassis, by adding heat exchangers outside the card enclosure, Sullivan says.

Liquid cooling

Most experts agree that even with the best improvements, that conduction and convection cooling can take designers only so far before they must resort to more drastic measures, and those measures most often involve some form of liquid cooling.

ISR Inc. in Liberty Lake, Wash., is a well-known company that has applied liquid spray cooling on military systems such as the U.S. Navy EA-6B electronic warfare aircraft, other military ageing aircraft, and the U.S. Marine Corps Advanced Amphibious Assault Vehicle-better known as the AAAV.

ISR’s spray cooling method sprays non-conducting inert fluids directly over components on circuit boards. The liquid boils and evaporates on contact with hot components, and later condenses and recirculates throughout the system

Liquid cooling in a variety of forms has been used in niche custom-design military and aerospace applications for many years, but it is only recently that industry experts have considered liquid cooling for COTS technology. Designers can use liquid to cool chassis sidewalls, flow liquid through pipes inside the chassis, or even use inert liquid to spray over components, or even can immerse components in nonconducting cooling liquids.

The computer system for the Lockheed Martin F-22 Raptor advanced fighter, for example, has made use of liquid flow-through cooling, as has the radar system aboard the Boeing F/A-18 Hornet fighter-bomber.

Liquid cooling has many benefits, other than its ability to remove vastly more heat than conduction or convection cooling can. Liquid often enables systems designers to put cooling only where they especially need it, by tailoring cooling solutions to specific modules, explains Michael Gust, manager of mechanical systems at Mercury Computer Systems, who made his comments in March at the Military Technologies Conference, sponsored by Military & Aerospace Electronics magazine.

Companies such as Parker Hannifin Corp. and Meggitt Defense Systems Inc. are among the industry leaders in providing liquid-cooling solutions for COTS components and systems. Parker is offering a liquid flow-through chassis for military and aerospace applications that meets the VITA 48.3 ruggedized enhanced design implementation (REDI) standards.

The liquid-cooled enclosure, which is for 6U-sized circuit boards, can provide cooling for standard VITA 48 cards or for VITA 48.3 liquid-flow through cards in the same enclosure, says Rex Harvey, principal engineer of the Parker Hannifin Advanced Cooling Systems Team in Mentor, Ohio.

The ability to mix standard and liquid flow-through cards in the same enclose, he explains, enables designers to apply liquid only to the especially hot cards that need it, and make broad use of COTS cards that do not operate at extremely high temperatures.

Not all liquid cooling must involve flow-through modules, however. Some approaches may use standard conduction-cooled cards and use liquid cooling and heat exchangers that cool the sides of the chassis.

Of the various kinds of liquid cooling, Harvey says liquid flow-through modules can dissipate 700 watts of heat using glycol or water as the cooling liquid. Liquid spray cooling, which Parker also can provide, can dissipate 40 watts of heat per square centimeter using a flurocarbon coolant.

Much of the industry criticism of liquid cooling involves claims that liquid systems are larger, heavier, more complex, and more prone to malfunctions from leaks than their conduction- and convection-cooled cousins.

Harvey and other proponents of liquid cooling counter, however, that those claims are not always true. Mercury’s Gust points out that liquid-cooled chassis can be small enough only to accommodate a heat exchanger, pump, reservoir, filter, and fluid-distribution piping. Depending on the application and implementation, Gust contends that liquid-cooled systems can be even smaller than air-cooled systems.

“If you get above 600 Watts, the size of the fan grows so significantly that it is larger than the pump and compressor system,” points out Gerry Janicki, director of business development at Meggitt Defense Systems Inc. in Irvine, Calif.

Reliability is a separate concern, however, yet Janicki points out that liquid flow-through systems can be more reliable than fans, which wear out over time.

In liquid-cooling systems “you have to ensure that you don’t have leaks,” Janicki says. “We have leaned that you don’t have joints or any assembled joints where liquid has to flow through a box. Each cold plate is sealed, so you don’t have worries ever of leaks into a box.”

Meggitt engineers are working on their third generation of liquid cooling systems, and have several lessons learned to offer. “Any time you have a joint you designed with vibration and shock loads there could be a problem,” Janicki says.

When it comes to engineering tradeoffs of liquid cooling vs. other approaches, Janicki says his engineers never consider liquid cooling for anything less than 250 watts per box. “At 250 to 300 watts you get a strange transition, so you need to make sure there is sufficient air flow around the box,” he says.

Between 250 and 600 watts per box, Janicki says liquid cooling is an obvious choice. For the need to dissipate even more heat than that, Meggitt engineers recommend a special cooling method called vapor cycle cooling, which essentially is liquid cooling attached to a refrigeration unit. Meggitt’s system is called the Compact Cooler.

With vapor-cycle cooling “you can keep the system at a very precise temperature,” Janicki says.

Key to advanced air cooling may be to build a better fan

Engineers at Xcelaero Corp. in San Luis Obispo, Calif., are designing high-performance fans for cooling electronics that officials say move more air with less power than typical electronics-cooling fans on the market today.

While about 15 cubic feet per minute (CFM) of air is standard for top quality fans today, Xcelaero offers a newly designed fan that moves air at 26 CFM, says Chellappa Balan, chief technical officer of Xcelaero.

The company offers a 40-millimeter fan for 1U electronic enclosures, and will offer an 80-millimeter fan for 2U enclosures later this year, says Matt Krause, Xcelaero’s chief marketing officer.

“We wanted to improve performance, almost twofold on the low end of the spectrum,” Balan says. “Designers can keep that efficiency as power savings, or they put the power savings into the fan to meet higher flow rates with much higher pressures at the fan.”

Most electronics cooling fans available today spin only at high velocities, and do not have the strength to move to a different gear and move the same or larger amounts of air at slower fan rotations, Balan says. “Our fans can move slower and achieve the same performance,” he says. “We do that through our aerodynamic design that creates higher flow rates and pressure rises with the same energy input to the fan.”

Balan brings a unique perspective to cooling fan design. He is a former aircraft turbofan jet engine designer for General Electric, where he helped design the company’s GE 90, CFM 56, and CF 6 jet engines.