The U.S. military and its partners from industry are meeting major milestones in various programs as they move closer to making laser weaponry a standard part of the U.S. arsenal.

By John McHale

Decades of research and funding have led to the development of a laser weapons component for the U.S. military. What was once science fiction is now becoming a viable tool as the first laser weapon—the U.S. Missile Defense Agency’s (MDA’s) Airborne Laser (ABL)—is set to be fielded within a couple years.

The ABL, contained in a converted Boeing 747-400F jetliner, will be another arrow in the MDA’s already formidable quiver, evidenced by its recent shootdown of a malfunctioning U.S. radar surveillance satellite, known as USA-193.

The U.S. is by far the leader in laser weapons technology, with many of its major laser programs already reaching important milestones in 2008.

Airborne Laser

Boeing, industry teammates, and the MDA achieved a significant milestone for the ABL missile defense program with the installation of all six chemical oxygen iodine laser (COIL) modules on the ABL aircraft at Edwards Air Force Base, Calif.

The six laser modules are linked together to achieve megawatt-class power using common industrial chemicals to create the system’s lethal beam. Contrary to what many may think, the ABL high-energy laser will not blow up the target, but heat it to such an extent that it implodes.

“ABL’s weapon system integration team has done a tremendous job installing major components of the high-energy laser aboard the aircraft, and they remain on track to reach the missile shoot-down demonstration planned for 2009,” says Scott Fancher, vice president and general manager of ABL integrator Boeing Missile Defense Systems.

“Completion of laser module installation means that the overall integration of the megawatt-class laser onto the prototype ABL aircraft is more than 70 percent complete after about five months of activity,” says Alexis Livanos, Northrop Grumman corporate vice president and president of the company’s Space Technology sector in Redondo Beach, Calif.—the laser provider for the ABL. He noted that the COIL took three years to assemble and activate.

Once plumbing and wiring installation occurs and final inspections of the laser are complete, system activation and ground tests of the laser inside the aircraft will begin. Facilities, testing, and safety procedures at Edwards are being upgraded to accommodate laser tests in the aircraft hangar.

To prepare for the current or high-power system integration phase, required laser parts were refurbished, and a streamlined planning and integration sequence was put in place. Substantial facility upgrades further positioned the ABL team to complete the laser module installation as part of the overall laser integration.

“Completion of the laser refurbishment in 2007 means required parts are available to the integration team for installation of the High Energy Laser,” says Dan Wildt, vice president of Directed Energy Systems for Northrop Grumman Space Technology.

“By implementing lessons learned and lean-plus process improvements, the team has reduced laser installation time on the aircraft to about one-third from what was required when the laser modules were installed in the system integration laboratory at Edwards,” Boeing’s Fancher says.

The laser modules were demonstrated in ground testing in late 2005 in the system integration laboratory at Edwards and completed the refurbishment phase in late 2007. ABL’s low-power beam control and fire-control systems demonstrated their capability in 2007 by tracking an airborne target, measuring and compensating for atmospheric turbulence, and firing a surrogate high-energy laser at the target. This dual-path approach demonstrated all of ABL’s key technologies. Integration of the high-energy laser in the aircraft will lead to ground and flight tests of the entire ABL weapon system, culminating in an airborne intercept test against a ballistic missile in 2009.

Perhaps the MDA’s most famous program, the ABL is designed to destroy missiles in their boost phase. The boost phase is the first phase of a ballistic missile trajectory its engines are firing. During this phase, which usually lasts three to five minutes for an intercontinental ballistic missile (ICBM), the missile reaches an altitude of about 125 miles, whereupon powered flight ends and the missile begins to dispense its reentry vehicles. The other phases of missile flight, including midcourse and terminal, take up the remainder of an ICBM’s flight time of 25 to 30 minutes.

The operational phase of the ABL begins with the six infrared sensors strategically placed on the aircraft that detect the exhaust plume of a boosting missile. Once a target is detected, a kilowatt-class laser, the Track Illuminator (TILL), tracks the missile and determines a precise aim point. The Beacon Illuminator (BILL), a second kilowatt-class laser, then measures disturbances in the atmosphere, which are corrected by the adaptive optics system to accurately point and focus the high energy laser at its intended target. Using a very large telescope located in the nose turret, the beam control/fire control system focuses the megawatt-class laser beam onto a pressurized area of the boosting missile, holding it there until the concentrated energy causes the missile to break apart, according to the MDA.

The ABL’s modified Boeing 747-400F, whose back half holds the high-energy laser, was designed and built by Northrop Grumman. The aircraft’s front half contains the beam control/fire control system, developed by Lockheed Martin, and the battle management system, provided by Boeing.

Boeing is the prime contractor for ABL, which will provide speed-of-light capability to destroy all classes of ballistic missiles in their boost phase of flight. ABL’s speed, precision, and lethality also have potential for other missions, including destroying air-to-air, cruise, and surface-to-air missiles.

U.S. Air Force officials also awarded Boeing with a $49 million U.S. Air Force contract to advance the state of the art in laser technology. Under the Laser Application Support and In-house Research and Development (LASIR) contract, awarded Feb. 1, Boeing will support research, design, development, and testing at Air Force Research Laboratory sites at Kirtland Air Force Base in Albuquerque, N.M.

Specific efforts will include:

- working to advance gas, hybrid electric-gas, and chemical laser systems, as well as technologies related to high-power fiber lasers, fiber laser pumps, non-linear optics, solid-state lasers, and diode-pump lasers;

- coordinating, preparing, and executing tests of laser effects;

- rapid prototyping of directed energy technology, including semiconductor lasers, thin-disk lasers, ultra-short lasers, laser-based infrared countermeasures, and mid-wave and long-wave infrared lasers; and

- supporting the Laser Center of Excellence, a joint Department of Defense/academic program that partners the Air Force Office of Scientific Research, Air Force Research Lab, Air Force Institute of Technology, University of New Mexico, and New Mexico Institute of Mining and Technology.

The Center’s efforts include gas, hybrid electric-gas, and chemical laser systems.

“This Air Force program represents an important opportunity for Boeing in continuing to help develop the next generation of laser weapon technologies,” Boeing’s Fancher says. “The various laser technologies being developed represent potential solutions to equip the warfighter with ultra-precision engagement capability.”

In addition to the Airborne Laser, Boeing leads directed energy research and development for various military applications, including the Advanced Tactical Laser, High Energy Laser Technology Demonstrator, and Tactical Relay Mirror System.

JHPSSL

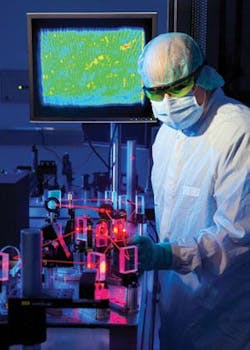

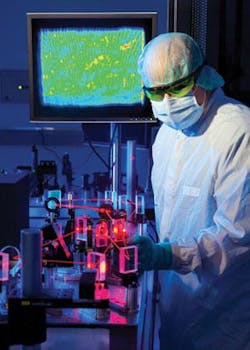

Northrop Grumman in Redondo Beach, Calif., meanwhile, is working on another important military project called the Joint High-Powered Solid State Laser (JHPSSEL) program to create kilowatt-class tactical weapons

The JHPSSL system is designed to accelerate solid-state laser technology for military uses, including force protection and precision strike missions for air-, sea-, and ground-based platforms.

Officials at Northrop Grumman have completed the second major demonstration milestone for the JHPSSEL Phase 3 program.

The team demonstrated a laser chain—the first part of a solid-state demonstrator laser designed produce 100 kilowatts of laser power, Northrop Grumman officials say. “With the successful demonstration of a complete laser chain—the building block of the fully integrated solid-state laser—the hardest part is over,” Wildt says.

The first laser chain (LC1) is a key component to the JHPSSL scaleable architecture, which combines eight laser chains of four gain modules each. Each laser chain is a compact 15-kilowatt solid-state laser. The company’s scaleable approach achieves higher power as more chains are added.

The laser chain milestone was demonstrated the end of last year. Power reached 15.3 kilowatts, exceeding the target requirement of 12.7 kilowatts; LC1’s run time was more than 300 seconds; and the electro-optical efficiency was 19.5 percent.

“Our team has developed a compact modular laser with excellent beam quality, which can be used alone or coherently combined with additional laser chains to reach 100 kilowatts and beyond,” says Jay Marmo, Northrop Grumman’s program manager for JHPSSL. “LC1 represents the first JHPSSL brassboard laser chain produced to the phase 3 design, proving both the production methods as well as the JHPSSL laser chain design.”

In 2008, the JHPSSL team will assemble and test Laser Chain 2 (LC2) and integrate it with LC1. The system alignment and phase control of the two chains will then be demonstrated. “Completion of the remaining six laser chains and their integration into the final system configuration is on track for a full power system demonstration of 100 kilowatts by the end of 2008,” Marmo says.

The JHPSSL program is funded by the Army Space and Missile Defense Command, Huntsville, Ala; Office of the Secretary of Defense - Joint Technology Office, Albuquerque; Air Force Research Laboratory, Kirtland Air Force Base, N.M.; and the Office of Naval Research, Arlington, Va.

ATILL

Northrop Grumman also received a Missile Defense Agency (MDA) contract for the second phase of a 5.5-year program to develop the Advanced Track Illuminator Laser, or ATILL—a six-kilowatt solid-state, pulsed laser for advanced MDA missions.

The four-phase program will support MDA and the Massachusetts Institute of Technology Lincoln Laboratory (MIT/LL) in building the next-generation Cryo Yb:YAG (ytterbium: yttrium aluminum garnet) solid-state laser track illuminator while improving packaging density and electrical efficiency.

During Phase 1 of the contract, Northrop Grumman supported the MIT/LL effort with laser system modeling and analysis, performed trade studies, and presented options at a conceptual design review in December. Following the 12 months of Phase 2, MDA will down-select to one company for the remaining two phases. The fourth phase will culminate in 2012 with delivery to the government of a flight-qualifiable brassboard laser system.

During Phase 1, the Northrop Grumman team conducted a four-month study focusing on system engineering and design trade-offs for the development of a packaged brassboard laser and participated in the technology transfer effort at MIT/LL. Brassboard design analysis and technology transfer with MIT/LL will continue through Phases 2 and 3, with fabrication, integration and testing of the brassboard conducted in Phase 4.

“ATILL is another opportunity to continue our leadership in high-power solid-state laser illuminators,” Wildt says. “Our previous experience in developing the ABL Beacon Illuminator and our recent, directly relevant experience on MDA’s Strategic Illuminator Laser program demonstrates the technology and packaging capability needed for success on ATILL.”

Northrop Grumman teammate Q-Peak Inc. in Bedford, Mass., has built the second most powerful Cryo Yb:YAG laser to date.

Northrop Grumman to sell Electro-Optical Systems to L-3 Communications

Officials at Northrop Grumman Corp. in Los Angeles, Calif., signed a definitive agreement to sell the company’s Electro-Optical Systems business for $175 million in cash to L-3 Communications in New York City. Completion of the transaction, subject to customary conditions including Hart-Scott-Rodino approval, is expected in the second quarter of 2008. Electro-Optical Systems, a part of the company’s Electronic Systems sector, produces night-vision and applied optics products and had sales of approximately $190 million in 2007. Headquartered in Garland, Texas, Electro-Optical Systems has approximately 1,000 employees.

“Our strategy is to acquire businesses that expand our core offerings,” says James W. Dunn, president of L-3’s Sensors and Simulation Group. “There is strong demand worldwide for image-enhancing products, and the addition of EOS’ products and technologies enhances our ability to meet that need. Including EOS, L-3’s EO/IR businesses will generate approximately $800 million in annual sales, with growth exceeding 10 percent.”

L-3 currently offers integrated imaging solutions, including EO/IR (electro-optical/infrared) sensors, high-definition turrets, tactical sights, and laser designators for air, land, and sea applications. EOS’ portfolio includes night-vision goggles, weapons sights, driver viewers, image intensification tubes, and applied optics products. The business will be integrated into L-3’s Specialized Products segment within the Sensors and Simulation Group.

L-3 Communications employs more than 64,000 people worldwide and is a prime contractor in aircraft modernization and maintenance, C3ISR (command, control, communications, intelligence, surveillance and reconnaissance) systems and government services.

To learn more about L-3, visit the company’s Web site at www.L-3Com.com.

Laser Energetics wins solid-state laser contract

Laser Energetics, Inc. in Princeton, N.J., won a contract worth $481,268 from ITT Corp. for a laser demonstration of an all solid-state frequency tripled Alexandrite laser using the LEI proprietary BrightStar technology. This contract is in support of the U.S. Army’s initiative to develop an all-solid-state laser for the next generation of chemical warfare agent sensor currently being developed by ITT.

The contract follows the Army’s selection of Laser Energetics’ BrightStar as the laser technology of choice for this remote sensing of chemical warfare agents. The technology was selected by a government panel following the panel’s evaluation of 20 different competing laser technologies from 18 laser companies. The panel’s evaluation and decision was made in part by Laser Energetics’ report on this all solid-state Alexandrite laser and the technical advantages of this tunable laser technology over other lasers, Laser Energetics officials say.

Laser Energetics has had a primary focus on its Alexandrite laser technology. These tunable solid-state lasers are unique in that they can be conductively air cooled to compete favorably against water-cooled lasers in many applications, company officials say. In addition, these lasers have a wavelength tuning range with a bandwidth of more than 250 nanometers. The company is pursuing markets that are diverse yet can use the same laser with their compact user-friendly design.

Neutralizing IEDs with lasers

Officials at Boeing Integrated Defense Systems in St. Louis demonstrated that the company’s Avenger-mounted laser system can neutralize improvised explosive devices (IEDs) and unexploded ordnance (UXO) currently threatening U.S. troops in war zones.

During laser firings at Redstone Arsenal in Huntsville, Ala., the Laser Avenger engaged and destroyed five targets representing IED and UXO threats. Laser Avenger, equipped with a 1-kilowatt solid-state laser, also destroyed two small unmanned aerial vehicles that were stationary on the ground.

“Boeing’s investment strategy is to move some of its new directed energy weapon systems into field demonstrations, and Laser Avenger is the first one we’re rolling out,” says Gary Fitzmire, vice president and program director of Boeing Directed Energy Systems. “Laser Avenger provides the speed-of-light and ultra-precision capability that the warfighter needs today to safely neutralize improvised explosive devices and unexploded ordnance.”

The Boeing-funded Laser Avenger was developed in eight months, company officials say.

Laser Avenger is a Boeing-funded initiative to show that directed energy weapons are relevant to today’s battlefield and are ready to be fielded. Boeing developed the system in only eight months, company officials say.

Laser Avenger also is the latest in a series of Boeing upgrades to expand the Avenger air defense system into an Agile Multi-Role Weapon System (AMWS) with ground-to-ground as well as ground-to-air capability. The laser was added while retaining Avenger’s ability to carry other weapons, including missiles and a machine gun. By building upon the Avenger, of which there are more than 600 fielded worldwide, Laser Avenger will take advantage of an existing global logistics network, Boeing officials say.

The laser segment of Laser Avenger will have uses beyond the counter-IED, counter-UXO mission. For instance, it could be upgraded to have a shoot-on-the-move capability and to destroy other kinds of targets, including low-flying unmanned aerial vehicles.

Officials at Northrop Grumman completes flight testing of latest-generation LITENING targeting system

Northrop Grumman Corp. in Rolling Meadows, Ill., announced the flight demonstration of the company’s new fourth generation LITENING all-digital precision targeting system.

During the first phase of flight tests held at the Air National Guard and Air Force Reserves Test Center in Tucson, Ariz., LITENING G4 demonstrated advanced targeting and surveillance capabilities unsurpassed by any other targeting pod, company officials say. In addition, LITENING G4 offers warfighters a new laser illumination technology that provides increased target capability, and improved situational awareness.

“Our LITENING G4 targeting pods will provide a sizable improvement in capability for the warfighter, a capability that will identify and designate targets at distances and clarity never experienced before,” says Mike Lennon, vice president of Targeting and Surveillance programs for Northrop Grumman’s Defensive System Division. “LITENING’s demonstrated spiral development process and ability to rapidly integrate, test, and field advanced technologies ensure our warfighters will have unprecedented situational awareness, target coordination, and first-pass weapon deliveries both today and, more importantly, tomorrow.”

Developed under the U.S. Air Force’s Laser Target Imaging program, the laser illumination technology was first demonstrated during Bold Quest, a U.S. Joint Forces Command-sponsored military exercise last fall at Nellis Air Force Base, Nev.

The LITENING G4’s advanced 1,024-by-1,024-pixel forward-looking infrared (FLIR) system provides significant enhancements in terms of recognition range and image quality, which enables operators more time to identify and track targets, as compared to the “512” FLIRs currently fielded. Moreover, the targeting pod’s enhanced color symbology, designed to support a new generation of aircraft color displays, provides a more viewer-friendly format that eases operator understanding of display information.

Northrop Grumman’s widely fielded LITENING AT (advanced technology) system is a self-contained, multisensor weapon-aiming system that enables aircrews to detect, acquire, auto-track, and identify targets for highly accurate delivery of both conventional and precision-guided weapons. LITENING AT features advanced image processing for target identification; coordinate generation for GPS weapons; a 1,024-by-1,024-pixel charge-coupled device television sensor; a laser spot tracker; and an infrared laser marker. LITENING G4, planned for delivery to U.S. forces this year, will add the most advanced 1,024-by-1,024-pixel FLIR sensor for improved target detection and recognition ranges under day and night conditions; new sensors for improved target identification; and other advanced target recognition and identification features.

To date, almost 500 LITENING AT pods have been ordered by U.S. forces and allied nations and more than 450 systems have been fielded, the largest number of any advanced targeting and sensor system, company officials say. LITENING AT is combat proven on AV-8B, A-10A/A+/C, B-52H, F-15E, F-16 blocks 15M-52, EA-6B, and F/A-18 aircraft. Together, all variants of the LITENING pod have amassed more than 800,000 flight hours, approximately half of which have been logged under deployed and combat conditions. LITENING recently set a world record for targeting pod availability by providing 95 percent availability consecutively for more than two years. The LITENING targeting system is currently deployed with the Air Force’s Air Combat and Air Force Reserve Commands, U.S. Air National Guard, and the U.S. Marine Corps, as well as allied users.