Military and aerospace equipment designers have a wealth of options available to fill the ever-increasing need for secure data storage in the field.

By Courtney E. Howard

Military and aerospace applications often involve intricate networks of advanced sensors, each gathering a wealth of data. More information is being gathered than ever before on the digital battlefield, including high-resolution photography and full-motion video. All this data must be stored, and done so securely. Military and industry professionals are working together to meet this ever-growing need for secure information storage.

Officials in the U.S. Department of Defense (DOD) understand the need for secure data storage in a wide range of military applications and operating environments. Inline Corp. in Sterling, Va., is working with the DOD, developing secure data storage approaches to meet this need.

Inline, a wholly owned subsidiary of IceWEB Inc., will provide data storage to one of the DOD’s combatant commands. The company’s TruEnterprise 444 is being deployed by the DOD to build a 48-terabyte repository for geospatial imagery. DOD officials require a scalable solution to accommodate expansive growth of geographic information systems (GIS) data, to more than 200 terabytes. Inline engineers have designed a storage system capable of scaling to 2 petabytes. Complex and heavy-data-lifting applications such as this need reliable, high-performance data storage, acknowledges Stephen A. Gill, vice president of global sales at Inline.

Info on the move

“The intelligence needs of the military are driving a flurry of activity in intelligence, surveillance, and reconnaissance (ISR) programs,” says Jaden Ghylin, technical director at Crystal Group in Hiawatha, Iowa. “ISR programs require a large amount of tactical storage space in order to capture the data that is being pulled in from a variety of sensors.”

Crystal Group’s storage products are satisfying a growing ISR need: the ability to capture and store hours and hours of high-resolution images and video while on the move. This feat—storing large amounts of data on a mobile platform—is not without its challenges.

“Vibration levels, temperatures, and altitude are the major challenges to utilizing traditional, rotational hard drives to achieve large storage arrays,” Ghylin explains. Due to the limitations of rotational media, Crystal engineers have developed a storage array based on solid-state drive (SSD) technology that can pack 10 terabytes of data into 4U of space.

In addition to extreme environmental tolerance, SSDs offer lower weight, smaller size, and less power consumption than a rotational drive-based storage system, Ghylin adds. “All these factors are very important to mobile platforms, particularly airborne platforms. Aircraft also require a method to rapidly off-load data to a ground station.” Given the large amounts of data involved, he says, the fastest method for off-loading data is through “Sneakernet”—physically removing the storage media from the airborne platform and transferring it into a ground-based system for archiving. “Crystal has addressed these needs through the use of SSD rugged drivepacks (RDp) which hold eight SSDs per pack. It allows the platform to off-load 10 terabytes of data in minutes, in order to rapidly get back out for another mission.”

Crystal Group engineers have completed work for the Gorgon Stare program involving airborne and ground-based storage systems. Gorgon Stare is the name given to a next-generation, sensor-based ISR package to be installed on the Air Force Predator/Reaper (MQ-9) unmanned aerial vehicles (UAVs). Gorgon Stare is intended to deliver a broad view of a battlefield, encompassing roughly a 1.5-mile area and as many as 65 video feeds.

In this application, two Crystal RS47F servers with SSD rugged drive packs (RDp) mount in the aircraft, providing more than 15 terabytes of storage capacity. A ground-based system also includes an RS47F with RDp, RS255 servers, and RSS639 storage systems, delivering more than 100 terabytes of storage capacity for archiving missions. After mission completion, the drive packs can be rapidly transferred from the aircraft to the ground-based RS47F for archiving to the RSS639 storage system, Ghylin explains.

In-flight file server

Officials at Harris Corp. in Melbourne, Fla., sought a novel storage solution for their work on U.S. Navy aircraft avionics. They found their solution at Smart Modular Technologies Inc., a manufacturer of memory modules, solid-state drives, and embedded computing subsystems in Newark, Calif.

Harris engineers selected Smart’s SSDs for use in its Mass Storage Unit (MSU), an avionic file server being developed under contract with Boeing Integrated Defense Systems for F/A-18E/F Super Hornet aircraft.

“The MSU enhances our ability to provide significant file storage for in-flight applications on the F/A-18 platform,” explains Steve Cook, program manager for the Harris Government Communications Systems Division. “The increased capacity and performance of today’s SLC (single-level cell) NAND flash drives allow us to support a broader range of applications with data consolidated from multiple sources. Coupled with their high reliability and long service life, today’s advanced SSDs from Smart Modular Technologies are an excellent fit for our application.”

Harris engineers selected Smart’s XceedSecure 2.5-inch SATA (Serial Advanced Technology Attachment) SSD for their in-flight file server application. XceedSecure high-performance SSDs range in capacity from 32 to 256 gigabytes and employ EraSure technology, secure erase features that comply with current military data-elimination standards.

A growing number of secure data storage devices, each fulfilling a specific need, are being employed on the digital battlefield.

“Size, weight, and power (SWaP) are still king for DOD deployment situations, which drives capacity per square inch and environmental aspect of components, final module specifications, and packaging,” says Joey Sevin, business development manager at Curtiss-Wright Controls Embedded Computing in San Diego. Curtiss-Wright Controls Electronic Systems Data Recording division, located in Fairborn, Ohio, provides rugged storage, network attached storage, and mission/flight recorders for military and aerospace applications.

The specifics of the mission typically drive the performance of the data storage to high capacity, data transfer, and reliability, Sevin continues. “Terabytes and multi-terabytes are not uncommon [in mil-aero applications], which drives the need for scalability and the need for industry-standard interfaces.” Curtiss-Wright engineers address reliability by implementing rigorous supply chain processes, including component selection and obsolescence and supply chain management, combined with thorough inspection, testing, and quality-assurance procedures.

Flexibility and mobility are important to the military, which requires additional security features—such as user authentication, protection of the data at rest and in motion, certified encryption, and key management/protection—because of the threat of systems being captured by the enemy, Sevin describes.

Curtiss-Wright’s data recorders provide security features like multiple mode key management and user authentication to provide strong protection and erasure of critical data. The solutions encrypt classified information as the data is placed to rest on the storage media. “The applications support the ability to destroy the key as it travels with the data in transport, so that the data can be rendered unclassified and useless by the courier of storage,” Sevins explains. “Or the key can be transported and protected separately from the data via separate transport handling and routing.”

Raw data

Because “we focus on collecting and storing raw digital data that comes directly from sensors, video, radar, and other data acquisition equipment, our users are most concerned with performance and fail-safe operation,” says Ken Owens, chief executive officer of Conduant Corp. in Longmont, Colo.

The company’s engineers design and manufacture specialized high-speed digital data recorders, able to uptake and record data flows at rates as fast as 800 megabytes per second, for military and aerospace clients. “Our clients demand that we handle this very high performance level for long periods of time,” Owens says. “Data loss is not an option with these highly sensitive applications.”

Owens and his Conduant colleagues are gaining more requests for ruggedized hardware, as certain operations move to the field. Because traditional disk drives are sensitive to shock and vibration, the company offers solid-state storage devices (SSDs) to build more reliable field units.

Conduant’s long-duration digital recording and playback disk systems are for applications that produce much raw, high-speed data, such as radio astronomy, high-resolution video imaging, and radar surveillance. “We are continually exposed to requirements that push the recording rates,” Owens says. “We see requests for recording rates that will exceed 1 gigabyte per second. There is no question that solid-state devices will become much more common as their prices continue to drop.”

Conduant was subcontracted to design and build a massively redundant, ruggedized storage and computing subsystem for an undisclosed prime contractor and application. The system required a large storage farm of as much as 2 terabytes connected to a server host along with eight processor boards for data manipulation and processing. Four independent servers, each with a primary and secondary path to the storage farm, were required for redundancy. The active server and processing boards needed network access, power to all components had to be individually controllable for power conservation, and the entire configuration had to be contained in a ruggedized chassis, cooled only by conduction, and able to survive high vibration and shock levels.

Conduant engineers delivered a system with commercial off-the-shelf (COTS) components, a mix of conduction-cooled 3U CompactPCI and VPX components, and a custom backplane that accommodates 12 single-board computers, 16 SSDs, 6 DC/DC power supplies, and two Gigabit Ethernet switch boards. The entire subsystem was designed to withstand a 20G shock force, wedge locks were included on all cards, and the SSDs are inherently shock and vibration resistant, Owen describes.

System considerations

Storage systems are required to have a useful life in military and aerospace system deployments for 10 years or more. “Believe it or not, some military mission flight recorders (black boxes) from the late 1970s are still in service,” admits Gary Drossel, director of product planning at Western Digital in Lake Forest, Calif. “Because deployments are so long and may have multiple project lives, military equipment OEMs require storage systems to have fixed bill of materials (BOM) with parts and components in service for the expected life of the deployment.”

OEMs should also consider the need not only to forecast drive life accurately, but also to monitor storage system usage in real time, particularly when it comes to long life for SSDs. Having access to this data can prevent unscheduled downtime from drive wear-out, and enable scheduled maintenance at proper intervals, Drossel says.

“Capacities and speeds are relative to each specific application and in most cases, military and aerospace designers value high reliability and endurance over speed. Since storage systems are required to operate flawlessly in extreme environments, they must be impervious to shock, vibration, and extreme temperatures,” notes Drossel. “Many applications also require low power consumption, so as to not take away CPU computing power and to extend battery life as long as possible.”

A critical need exists to protect systems from the effects of power anomalies, such as an ungraceful power down, brownout, power spike, or unstable voltage level. Power anomalies are a main cause of storage system field failures and must be a design consideration, Drossel explains.

Data security is another obvious priority for storage in mil-aero applications. Today, most military-grade storage systems require some kind of “verified erase,” where data can be removed with zero traces, Drossel explains. “Particularly for storage systems that could potentially fall into enemy hands, data security mandates may include a fast, verified erase for sanitized data erasure or drive destruction. Many storage OEMs selling to military and aerospace designers have built proprietary firmware into their SSDs and HDDs to meet these stringent requirements.”

Western Digital integrates a suite of patented security technologies into its SSDs to safeguard data and protect software IP from breaches, theft, or malicious overwrites. SiSecure features five user-selectable security features, whereas SiKey ties a specific WD SiliconDrive to a specific host system. “If a WD SiliconDrive is removed without authorization and placed in another host system to boot and access data, the drive is immediately destroyed, which is a critical consideration for portable data,” Drossel describes. SiZone enables as many as five independent data security zones, SiSweep ensures ultra-fast data erasure, and SiScrub initiates ultra-fast data erasure followed by a programmed pattern for military-grade verified data erasure. SiPurge is used to erase data quickly and render the drive non-recoverable.

SSDs and HDDs

Ultimately, military and aerospace storage choices really do depend on the usage model at hand, Drossel states. “Write intensive, 24/7 usage models mean failure is just not an option due to battlefield conditions and extreme environments, so SSDs are the preferred storage choice. When the highest capacity possible for the best cost per gigabyte is the mandate, HDDs (hard disk drives) win every time.”

Crystal Group’s Ghylin has begun to see a noticeable shift from rotational media to SSDs with the company’s customers. Still, more than 90 percent of the hard drives sold are based on rotational media due to cost and capacity, he says. “This is changing almost monthly as SSD prices come down and capacities go up. According to ResearchandMarkets.com, the CAGR for enterprise-grade SSD drives will be 155 percent through 2013. This trend lines up fairly well with what Crystal Group is seeing in the marketplace.”

Military and aerospace requirements for storage mirror those of other embedded systems: OEMs want higher storage capacities, with faster host system interfaces and the availability of a variety of storage form factors, Drossel says. “In an integrated, networked battlefield, an enormous amount of data is streamed and stored. Small-capacity storage doesn’t give users the ability to record the whole data stream, frequently requiring users to compress the data, often leaving out vital bits of information.” The issue is solved with today’s SSDs, which offer higher capacities and fast host system interfaces, Drossel says.

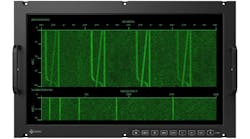

Advances in military video, audio, and instrumentation surveillance technology have resulted in the need for higher performance, SSD-based mission data recorders. Higher-resolution surveillance cameras have driven up capacity requirements and increased the number of data streams coming into the recorder, while features such as simultaneous record and playback have pushed performance to the limit, Drossel continues. “The latest SSD-based mission recorders are able to receive multiple streaming battlefield videos and data from manned or unmanned systems and display them in real time, improving situational awareness and effectiveness against critical targets.”

Today, SSDs offer capacities of as much as 250 gigabytes with performance as fast as 250 megabytes per second read and 190 megabytes per second write with significant random IOPs (Input/Output Operations Per Second) that enable thousands of random reads per second, delivering images in real time with no interruptions, stops, or stutters. “In addition,” Drossel says, “the new SSD mission recorders are engineered for harsh environments and are imperviousness to shock, vibration, and extreme temperatures, while delivering ultra low power consumption and advanced storage algorithms that guarantee maximum reliability and long product lifecycles.

“It is important to underscore that not all SSDs are created equal; integrated security and other advanced features make the difference,” Drossel explains. The most significant consideration for equipment designers selecting storage for a military and aerospace application is its usage model. “In order to take advantage of the most diverse levels of COTS SSDs, security requirements of military and aerospace storage must be revisited and well-understood by designers.”

Secure storage with software

Thin-client architectures and real-time operating systems (RTOSs), such as those offered by Green Hills Software, LynuxWorks, and Wind River, are increasingly being employed in military and aerospace environments to protect stored, mission-critical data.

Green Hills Software in Santa Barbara, Calif., during Avionics USA in June, unveiled its RTCA/DO-178B Level A-compliant Partitioning Journaling File System, PJFS-178B. A high-assurance software component for the company’s Integrity-178B RTOS, the “Journaling File System provides multiple Integrity-178B partitions with concurrent power-fail safe access to an underlying file system,” explains a representative. The PJFS-178B Client enables a safety- or security-critical application to access the file system, whereas the PJFS-178B Server manages access to underlying storage devices. The Client and Server can reside in the kernel or any virtual partition, and a single host PJFS-178B file system can service multiple file system clients at different safety levels.

LynuxWorks in San Jose, Calif., has partnered with Empress Software to unveil the Empress Ultra Embedded Database v10.20 on the LynxOS RTOS 5.0. Targeted at mission-critical military and aerospace applications, the software combination ensures the security of critical information stored in an embedded systems data management system.

More Military & Aerospace Electronics Current Issue Articles

More Military & Aerospace Electronics Archives Issue Articles