Navy researchers to apply SiOnyx proprietary Black Silicon technology to SWIR night-vision sensors and weapons

DAHLGREN, Va., 31 May 2012.Night-vision and electro-optics experts at the U.S. Naval Surface Warfare Center Dahlgren Division in Dahlgren, Va., are looking to infrared detector designers at SiOnyx Inc. in Beverly, Mass., to fabricate low-cost silicon-based detectors in the short-wave infrared (SWIR) spectrum for night-vision and other infrared sensor applications.

Navy researchers announced plans last week to award a sole-source research contract to SiOnyx to use the company's proprietary "Black Silicon" semiconductor process to develop advanced SWIR detectors. The Naval Surface Warfare Center Dahlgren Division focuses on weapons technology development.

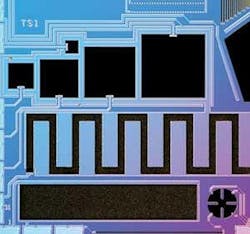

SiOnyx experts use a complementary metal-oxide-semiconductor (CMOS)-compatible process to develop inexpensive Black Silicon infrared detectors, which offer high optical sensitivity in the near-infrared (NIR) and SWIR spectral regions for military, medical, and commercial applications.

Developing silicon-based infrared detectors is less expensive, and can be more reliable, than using materials like indium gallium arsenide (InGaAs) and mercury cadmium telluride (HgCdTe), experts say.

Silicon is inexpensive and reliable largely due to a large and mature microelectronics manufacturing industry. Although silicon is a leading light-detecting material for imaging applications, its native band-cutoff wavelength and absorption properties lead to diffuse imagery in the near-infrared spectrum, and insensitivity in the SWIR spectrum.

SiOnyx experts have found a way to push the boundaries of silicon in the company's Black Silicon process to make this affordable material competitive in performance with more exotic and expensive materials.

SiOnyx engineers manufacture Black Silicon in a CMOS process that uses short-pulse lasers to alter the photoconductive and absorptive properties of silicon, which can lead to photodetectors substantially more sensitive to light in the NIR and SWIR bands.

While SWIR sensors cannot function in total darkness like long-wave infrared sensors can, SWIR sensors particularly are attractive for aerospace and defense applications for their ability to detect dirt that has been recently turned over, differentiate between natural foliage and camouflage, see through glass windows, and recognize human faces.

With the infrared-sensing properties of black silicon, true digital daytime and nighttime imaging could become as pervasive as visible digital photography is today, SiOnyx officials say.

Navy researchers say using the SiOnyx Black Silicon process could increase the quantum efficiency of silicon over standard silicon, and lead to a low cost, enhanced SWIR detector.

SiOnyx was founded in 2006 by Professor Eric Mazur and Dr. James Carey of Harvard University in Cambridge, Mass. SiOnyx focuses on improving the performance of light-sensing devices in military, consumer, and commercial applications.

The Naval Surface Warfare Center Dahlgren Division research and development center focuses on biotechnology; chemistry; mathematics; lasers; chemical, mechanical, electrical and systems engineering; physics; and computer science for weapons applications.

For more information contact the Naval Surface Warfare Center Dahlgren Division online at www.navsea.navy.mil/nswc/dahlgren. or SiOnyx at http://sionyx.com.

Follow Military & Aerospace Electronics and Avionics Intelligence news updates on Twitter