Smaller sensors make unmanned vehicles smarter

Tomorrow’s sensors will be modular, digital, fused, and networked

By Ben Ames

United States troops in Iraq use unmanned vehicles for dangerous jobs that demand endurance and reliability. In the air, an unmanned aerial vehicle (UAV) can linger for hours while spying on a certain target. And on the ground, an unmanned ground vehicle (UGV) can look for wires on a roadside bomb without risking human life.

Now designers are using new technologies to empower unmanned vehicles to perform new missions. With lightweight sensors and automated weapons, UGVs can do far more than explosive ordinance disposal (EOD).

The latest generation of UGVs can also perform reconnaissance, surveillance, and target acquisition (RSTA), as well as act as small mobile weapons systems (SMWS).

To do this, the UGVs need smaller, lighter sensors and they need to be armed. Yes, the UAV is no longer the only robot with self-defense tools. Certain ground vehicles now carry rifles, machine guns, and grenade launchers.

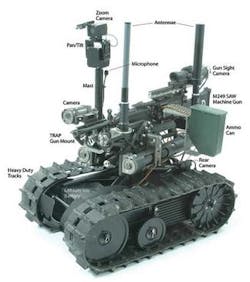

TALON

Soldiers in Kuwait and with the U.S. Army ARDEC (Armament Research, Development, and Engineering Center) at Picatinny Arsenal, N.J., are testing prototypes of an armed version of the Talon, a product of Foster-Miller Inc. in Waltham, Mass. It is called SWORDS, for special weapons observation reconnaissance direct-action system.

The vehicle can crawl along at four miles per hour, controlled through radio-frequency (RF) signals or a fiber-optic wire. The soldier driving this vehicle gets feedback with an operator control unit he can either wear on his person or stow in an attaché case.

When he spots a threat, the soldier can deploy the robot’s weapon. Each unit can carry a rifle such as the M16 or Barrett 50-cal., or a machine gun like the M240 or M249. Add a different mount, and it can carry a 40-mm grenade launcher or M202 anti-tank rocket.

Engineers designed the original Talo for explosive ordinance disposal. It is a tool used by soldiers to inspect and disarm suspicious suitcases or artillery shells. Troops like the rugged unit because it can go nearly anywhere; the 100-pound robot can right itself if toppled over, then climb stairs or wade through the surf.

Troops can also configure the robot for different tasks-adding real-time chemical and radiation sensors to test a hot zone, or steering a lightweight, 60-pound version with cameras and microphones through a surveillance mission.

There was only one thing missing-if the reconnaissance robot found a target, it could not react. So Foster-Miller engineers added weapons, says Bob Quinn, general manager of Foster-Miller.

“The soldiers worked with us to add a Marine Corps weapon-system mount, so we could use weapons and ammo that were already safety certified. The aiming platform we use is already in the hands of soldiers.”

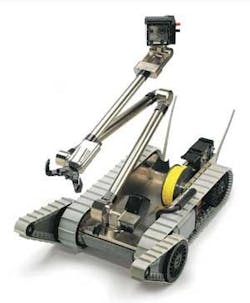

PackBot

Feedback from soldiers also prompted engineers at iRobot, in Burlington, Mass., to make improvements to their popular PackBot.

Navy leaders recently ordered 150 more PackBot robots, also used in EOD missions to disable booby traps in Iraq. The $18 million contract from Naval Sea Systems Command (NAVSEA) in Washington calls for rapid deployment; they need all the units delivered by the end of 2005.

That will more than double the number of robots now in Iraq, says Tom Ryden, director of sales and marketing for iRobot’s government and industrial robotics division.

Soldiers there wanted to use the robots to do more than simple EOD missions. So designers at iRobot added chemical sensors and lasers to the PackBot head.

They also use EOIR (electro-optical infrared) sensors from Insight Technology of Londonderry, N.H. Those tools allow soldiers to assemble PackBot as a scout version for reconnaissance missions, complete with laser range-finders and night-vision illuminators.

Soldiers also asked for more muscle. One great advantage of the PackBot is its size-at just 55 pounds, it can be transported by a single soldier. But many of the roadside bombs in Iraq use unexploded 155-mm shells, which can weigh more than 115 pounds.

“Soldiers wanted to know if it could move those. So we made a tool to lift and cradle it in the back of the robot with a one-button push,” Ryden says.

They also made it easier to drive.

“When you teleoperate, you really are remote from the machine,” he says. “We added a radio, so soldiers can hear the motors, and whether the tracks hit something a little harder. They get a better perception of actually being in the robot. When you’re in a car, you can hear the tires squeal if you turn sharply, but not with a robot.”

SUGV

The next big step in military robotics will be the Army’s Future Combat System.

Designers at iRobot are building the SUGV for that task. This robot will weigh less than 30 pounds, so a single soldier can easily carry and deploy it in the battlefield using a standard backpack. Using familiar PackBot subsystems, the SUGV will carry up to seven different payloads, and have enough mobility to carry those sensors through caves, tunnels, and drainage pipes.

“Robotics are unique because of the tight integration between their electronics, mechanics, and software,” he says. “We’re developing the SUGV to be smaller and lighter by a significant amount than the Packbot. And we’ve added radios and integrated computers so it will be compliant with JTRS Cluster 5. That will allow the robot to be a data node on the network.”

Future Combat System

Communication is crucial, because the entire FCS system will be a networked “system of systems,” comprising 18 individual platforms plus the network and the soldier, according to Boeing Co., St. Louis, the lead systems integrator.

In the battlefield, FCS will link soldiers with manned and unmanned ground and air platforms and sensors. Ultimately, FCS will allow U.S. troops to be fast and versatile, as part of the Pentagon’s vision of the Future Force Warrior. For more information, see www.boeing.com/fcs.

Army researchers are now developing another part of FCS-an armed robotic vehicle (ARV) that uses autonomous sensors and weapons to minimize soldiers’ battlefield exposure.

In April they awarded a $30.9 million contract to United Defense Industries, Arlington, Va. (now a unit of BAE Systems), to integrate unmanned platform technologies from Army and commercial developments into a single ARV. Subcontractors include General Dynamics’ robotics system division, Westminster, Md., and Omnitech Robotics, Englewood, Colo.

Engineers will then test the vehicle in experiments planned for September 2006 and March 2008. The process is managed by the Tank-Automotive Research, Development and Engineering Center (TARDEC) at the Army’s Tank-automotive and Armaments Command (TACOM) in Warren, Mich.

Grand Challenge

Another way to drive robotics research is prize money. Two million dollars will go to the winner of the Grand Challenge, a race for unmanned vehicles sponsored by the U.S. Defense Advanced Research Projects Agency (DARPA).

In the race’s last running, none of the entrants was able to complete the 175-mile desert course, much less beat its 10-hour cutoff time. But this year’s contest is attracting some big names, from Caterpillar Inc., Peoria, Ill., to schools like Princeton, Stanford, and M.I.T.

In April, DARPA leaders narrowed the list of contestants to 118 teams. Just 20 will compete for the prize on Oct. 8. For more information, see www.darpa.mil/grandchallenge.