Rugged circuit board pins for power supplies and power converters introduced by Mill-Max

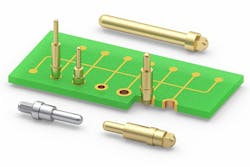

OYSTER BAY, N.Y. – Mill-Max Manufacturing Co. in Oyster Bay, N.Y., is introducing six press-fit printed circuit boardpins for power supplies, power converters and any other device subject to blind mating or rough handling.

These circuit board pins feature multi-faceted (polygon) geometries and are suitable for solderless circuit board termination or for direct soldering to the board.

When these pins are pressed into a plated through-hole the major or circumscribed diameter points of the polygon are set or embedded in the hole while the flat sides of the minor or inscribed diameter feature provide relief, leaving the remainder of the plated through-hole barrel intact.

This leaves internal board layers connected when the pin presses in. With a properly specified hole size, the polygon-shaped press-fit feature will secure the pin in the hole while maintaining continuity throughout all the layers of the circuit board.

Mill-Max builds either square or hexagon shaped press-fit features to suit a variety of hole sizes and assembly requirements. Square press-fit features normally leave a larger gap between the flat side of the feature and the hole, useful for solder flow and venting of gasses, while a hexagon feature will provide more interference and greater retention.

The square brass 8237-0 pin is 0.06 inches in diameter with no vent; the square brass 5920-0 pin is .08 inches in diameter with no vent; the hexagonal brass 6025-0 pin is .04 inches in diameter with a side vent; the hexagonal brass 6035-0 pin is .061 inches in diameter with a side vent; the square brass press-fit 6834-0 pin is .04 inches in diameter with a side vent; and the square tellurium copper press-fit 6835-0 pin is .08 inches in diameter with a side vent.

These pins often are used in applications with more demanding mechanical and electrical requirements such as power supplies, power converters and any device subject to blind mating or rough handling.

They typically are staked into a circuit board at the press-fit end and either soldered or plugged in at the pin end. These pins are suitable for high-current applications, and the pin material is typically brass but for greater electrical conductivity and more efficient heat dissipation tellurium copper is also available.

For more information contact Mill-Max online at www.mill-max.com.

Learn more: search the Aerospace & Defense Buyer's Guide for companies, new products, press releases, and videos