Those involved in the embedded computing industry today face a paradox of sorts: demands from the Pentagon and from the defense industry to move commercially developed technology to the field as quickly as possible, while at the same time specifying open-systems standards, which can be notorious for moving slowly.

Talk about open-systems embedded computing standards like the Sensor Open Systems Architecture (SOSA) and the Modular Open Systems Approach (MOSA), and often the first thing people think of is the time necessary to learn the ins and outs of these guidelines, and also the time it takes to certify compliance. Quick-turnaround technology rarely enters the conversation ... at least at first.

As it turns out, standards-based embedded computing actually may be nimble enough for all but the most stringent demands to get systems developed and out to the field no later than yesterday. As today's open-systems standards evolve -- and as technology providers and systems designers become familiar and comfortable with them -- it's dawning on the industry that the standards approach might not be as slow as first thought, and that over the long term, standards are the way to go for rapid technology development, sustainment, and upgrades.

Influence of the Ukraine war

Military electronic technology for decades has moved at a snail's pace from development to fielding, and that's been considered the norm -- until only recently. The Ukraine-Russia war has demonstrated conclusively that military electronics can be developed and deployed quickly and effectively on a shoestring budget.

"We are seeing a war being prosecuted with stuff found in the garage and on the shelves at Wall Mart," points out Chris Ciufo, president and chief technology officer at embedded computing specialist General Micro Systems Inc. (GMS) in Rancho Cucamonga, Calif. "In Ukraine we have seen breathtaking use of technology, their ability to modify it, and their creative doctrine on the battlefield."

Ciufo says he's astonished at how quickly and effectively that designers in Ukraine can capitalize on inexpensive technologies. "Look at their drone swarm," Ciufo says. "Their most effective attack was with camouflaged recreational vehicles launching their drones, and bombing aircraft on an airfield. We saw their drone swarms armed with electronic single-munitions and a backup technology with a fiber optic link."

He says these Ukrainian attack drones cost about $8,000 apiece. "The companies that make drones in this country ... these are not $8,000 machines; these are millions of dollars machines. This is low-cost technology being used by both sides to great effect. We have talked about asymmetric warfare before, but now it is an order of magnitude advanced from that. It's every bit as sophisticated as what the U.S. is deploying today."

These makeshift weapons that have kept Ukraine in the war against a numerically superior Russia, to say the least, are not standard. Although these off-the-shelf technologies may not represent the state of the art in weaponry, they do illustrate the value of making do with what you have, right now, on a budget you can afford.

Standard vs. non-standard

"The U.S. Department of Defense has awakened to this, and the government now is looking at non-standard technologies and companies that might be brought to bear on these problems," says GMS's Ciufo. "The government wants to partner with Silicon Valley companies to bring their technologies onto the battlefield quickly and cheaply. They want to find the technology that solves the need, and apply it."

As an example, Ciufo cites the U.S. Army's Soldier-Borne Mission Command (SBMC) next-generation digital awareness and mission command system designed for company-level and below infantry operations. It seeks to integrate augmented reality, night vision, and artificial intelligence (AI) into soldier-worn headsets and systems.

The SBMC is the latest iteration of the Army's Integrated Visual Augmentation System (IVAS), which originally was a $22 billion contract to Microsoft. IVAS didn't succeed because of user acceptance issues, significant technical flaws, and persistent physical discomfort of soldiers during testing.

The IVAS contract management moved earlier this year from Microsoft to Anduril Industries in Costa Mesa, Calif. Anduril and Rivet Industries in Washington now are the SBMC prime contractors, and seek to develop a next-generation situational awareness and mission command system that integrates data from soldiers, sensors, and mission systems.

For its part, Anduril is partnering with Meta in Menlo Park, Calif. -- parent company of Facebook -- to develop advanced augmented reality and mixed reality devices for U.S. soldiers. Together, the companies are building augmented-reality products like helmet-mounted displays that offer enhanced vision, night vision, thermal imaging, and real-time battlefield intelligence. This partnership takes advantage of Meta's augmented and virtual reality research and combining it with Anduril's Lattice command and control software. The Army awarded The Rivet and Anduril teams separate $195 million contracts on 4 Sept. 2025 for the SBMC.

The point is that the contracts to Anduril and Rivet "are less than one-tenth of what the Army were predicting to spend with a different vendor," Ciufo says. "Non-traditional vendor partnering with the DOD will change our marketplace."

Even advocates of standards-based embedded computing design acknowledge that non-standard technology may be the best choice -- especially when a system isn't expected to stay in use for long, and where long-term sustainment and systems upgrades are unlikely to be necessary.

"There is a balance there, in just doing it all in a proprietary way, versus trying to work within the standards mechanisms we have today," says Ken Grob, director of embedded technologies at Elma Electronic in Fremont, Calif. "There is overhead going both ways, yet one can have a better ecosystem by going through the standards, but there are challenges that not even the standards can keep up with. Anything that needs to be deployed next month won't be able to go through the open-standards approach."

Benefits of open-systems standards

Despite its reputation for being a slow mover, standards-based embedded computing design over the past few years has shown itself to be fast, resilient, and a driver for quick systems design and technology insertion. Of particular influence has been the Modular Open Systems Approach (MOSA) -- not itself a standard, but an integrated business and technical strategy primarily in use at the DOD competitive, affordable, and adaptable systems acquisition and sustainment throughout the system life cycle.

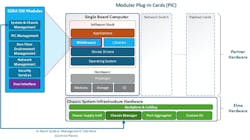

MOSA employs open-systems standards like SOSA to build systems that are loosely coupled and composed of interoperable modules with designated interfaces. This approach enables independent acquisition of modules from different vendors, while reducing life cycle costs and risks. MOSA enables incremental capability upgrades, promotes reuse of assets, and supports faster technology integration in defense systems. It also requires an open business model emphasizing transparency and collaboration across the defense enterprise.

"We have the mandate from the government to follow the MOSA approach, so SOSA becomes a standard that adheres to the MOSA approach," says Elma's Grob. Over the past three to five years we have had people pick it up and use it, and we're seeing they are having less issues with initial hardware integration. A few years back you could not take a card from one manufacturer and bring it into another manufacturers slot and not have problems with I/O."

The MOSA approach offers guidelines to map I/O and power schemes, as well as thermal management. "Initially it has saved people a bunch of time in specifying what they want, and to match that board to a backplane profile," Grob says. "It will turn on, and it will work."

The benefits of open-systems embedded computing don't end there. "Open-systems standards are a strategic imperative, not just a technical requirement," says Wayne Silvia, principal mechanical engineer at Atrenne Computing Solutions LLC in Brockton, Mass. Atrenne specializes in industrial embedded and rugged computing solutions for mission-critical applications.

"The most influential standards are those that champion modularity, interoperability, and long-term sustainability for mission-critical applications," Silvia says. "These standards translate directly into tangible benefits for customers, including reduced development time and cost, mitigation of obsolescence, and enhanced interoperability."

Standards for embedded computing

Among the most influential emerging open-systems standards for embedded computing are VITA 90, also known as VNX+; VITA 100 that could add a new 4U high-performance embedded computing board form factor; and the evolving Sensor Open Systems Architecture (SOSA) standard.

VITA 90 VNX+ is an evolving standard for extremely small embedded computing boards for applications like rugged, space-constrained environments such as uncrewed aerial vehicles (UAVs), ground vehicles, satellites, and C4ISR pods. VNX+ is to be the successor to the earlier VITA 74 (VNX) specification and introduces significant advances in performance, modularity, and interoperability.

VITA 90 VNX+ is a credit card-size board that is designed to meet the growing needs for improved size, weight, and power consumption (SWaP) VNX+ uses a rugged, low cost, and fast serial fabric interconnect based plug-in module. VNX+, while not offering the performance of VITA 100 3U, 4U, or 6U modules, primarily is for extremely small applications in which 3U VPX cards simply are too large.

Key parts of the VITA 90 standards are VITA 90.0, the base standard; VITA 90.1, its modular profiles; VITA 90.2 for coaxial and optical I/O); and VITA 90.3 for power filtering, conversion, and energy storage; VITA 90.4 for advanced cooling and retention; and VITA 90.5, also called SpaceVNX+, for space-based versions of these small-form-factor cards.

The emerging VITA 100 standard, expected to be ratified in early 2026, has the potential to double I/O board and backplane connector speeds over OpenVPX, breathe new life into 3U and 6U embedded computing architectures, and add a new 4U standard board size to accommodate the relatively large sizes of state-of-the art microprocessors, field-programmable gate arrays (FPGAs), general-purpose graphics processing units (GPGPUs), and other high-performance components.

VITA 100 is an evolution to OpenVPX, VPX, and related mechanical standards while embracing a shift in technology and capability with at least double the pin density, speed, and power for electrical contacts. Some of the first VITA 100-compliant products are expected in late 2026 or early 2027. VITA 100 will use the typical 3U and 6U size board formats, but a 4U size also may be implemented to accommodate advanced embedded computing processors and other components that might not fit on 3U VPX cards.

The latest development in the Sensor Open Systems Architecture (SOSA) standard is the release of the Technical Standard for SOSA Reference Architecture, Edition 2.0, Snapshot 3, announced by The Open Group SOSA Consortium last June. This snapshot includes significant updates and new features for inclusion in Edition 2.0 of the standard upon its official release.

Key updates in Snapshot 3 are improvements to the SOSA data model; revision and separation of electrical and mechanical sections; content on hardware acceleration to standardize interfaces; updates and improvements to hardware sections for 3U and 6U board formats; updates to container language and in-band and out-of-band content; security content updates for attestation, SOSA module 6.3, and encryptor/decryptor; integration of military directed-energy weapon system reference architecture V1.1; a SOSA Space Appendix that introduces 3U form factor plug-in card slot profiles, extensions for power supply cards, slot profile pitches, board length, and space-specific alternative module profile scheme strings; and directed energy weapon system-specific modules detailing directed energy source, beam transport, beam director, deconfliction safety, thermal management, and local sensors.

The road forward

Have embedded computing systems designers anything to fear from new and emerging standards? Probably not. "In the past we talked about sensor processing in a box with six single-board computers and a network switch to hold it all together. Now we might want to do sensor processing with three boards with an AI approach. It's just a different mix of components, and that's not different from what we have been doing for a long time," says David Jedynak, vice president of strategy for defense solutions at the Curtiss-Wright Corp. Defense Solutions segment in Ashburn, Va.

"There will be lots of new, but it doesn't disrupt the way we have been approaching this market," Jedynak says. "There doesn't need to be a standard for an AI card. It is the very fact of open standards that we can do that. It seeks to draw the appropriate lines between the components, such that lots of innovation can occur in the black boxes, and keep the interfaces among them the same."

About the Author

John Keller

Editor-in-Chief

John Keller is the Editor-in-Chief, Military & Aerospace Electronics Magazine--provides extensive coverage and analysis of enabling electronics and optoelectronic technologies in military, space and commercial aviation applications. John has been a member of the Military & Aerospace Electronics staff since 1989 and chief editor since 1995.