ISR ships SprayCool aft power supply for flight-testing

By John McHale

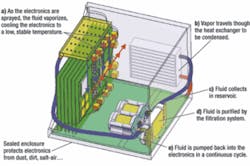

CLARKSTON, Wash. — The first SprayCool aft power supply (SC-APS) for aircraft applications has passed flight-testing in the U.S. Navy's EA-6B Prowler electronic warfare aircraft.

Delivery of the unit marks a major milestone for ISR and its SprayCool technology, which has had many doubters over the years who claimed liquid-cooling systems would never fly, but ISR engineers have proved them wrong.

"The demonstration of SprayCool technology in the E A-6B represents a significant enabling technology for the deployment of advanced airborne electronics and will serve as a proving ground for other Navy aircraft needs," says Navy Capt. John Scheffler, the EA-6B program manager at the Naval Air Systems Command (NAVAIR) at Patuxent River Naval Air Station, Md.

The new SprayCool APS demonstrates the successful application of evaporative spray cooling in a tactical aircraft environment. "The SC-APS operated trouble free during flight simulation testing including launch-and-landing, turbulence, and flight acceleration simulations." says Rich Woodruff, contact for NAVAIR's Small Business Innovative Research (SBIR) contract that produced the new power supply.

SprayCool technology also raises the bar for dealing with extremely high heat density. The SC-APS can handle six to 10 times the heat generated by the legacy air-cooled version, ISR officials say. "The door has been opened to the application of high performance, highly reliable electronics in tactical aircraft," Woodruff says.

In a step beyond the legacy power supply, the new SC-APS can operate without cooling air for one hour, a feature that will simplify the task of performing ground diagnostics and maintenance while eliminating the need for additional ground support equipment, ISR officials say. The end result is added confidence prior to take-off that the Prowler will meet its mission requirements, all in a package that is 10 percent lighter than the legacy unit, ISR officials say.

The biggest challenge in adapting a SprayCool system for aircraft was how to move fluid when the aircraft is in 0 G or when the aircraft is making sharp turns left and right and during other extreme changes in attitude, says Ray Joseph, director of general sales for ISR. So ISR engineers designed an attitude-independent valve that regardless of the aircraft's orientation will get the fluid moving, he says.

The ISR cooling system underwent aircraft CVS (carrier suitability) tests "to make sure the product as built is suitable for the rigorous demands of life on an aircraft carrier flight deck," says military consultant retired Navy Capt. Chuck Nash.

During the catapult launch and trap test "catapult shots take the aircraft from standing still to 170 mph in about 2.2 seconds," Nash says. "This imparts 54 transverse "Gs" and a tremendous amount of vibration on every thing in the jet. A trap is an arrested landing .referred to in the Navy as a "controlled crash."

The jet slams down at about 700-feet- per-minute vertical velocity (does not flare for a squeaky touch down like an airliner or Air Force landing) and a forward speed of about 155 mph and comes to a complete stop in about two seconds. Again, the transverse "G" loading, vibration, and shock are significant."

This causes sudden and jarring landing on the deck, he adds. "Maneuvers are performed at high speed, off center, and other "non-normal" landing executions, simulating real-life behavior of the aircraft in various carrier landing scenarios.

Flight operations test determine how the system performs during aerobatics and cold flight, Nash says A series of vertical, inverted, positive, and negative "G" maneuvers, both transient and steady state, are performed. Parameters are as high as 34,500-feet elevation, and operation in –35 degrees Celsius for 30 minutes. Hi-G maneuvers require as much as 4.3 Gs for 30 to 45 seconds and 0 Gs for as long as 13 seconds, Nash adds.

Signal Technology Corporation's Keltec Division, ISR's subcontractor on this effort, was integral in the design of the SC-APS, ISR officials say. The power- supply modules are designed and packaged for SprayCool using commercial off-the-shelf (COTS) components without heat sinks, taking full advantage of the COTS-viability and weight-reduction benefits of SprayCool technology. The system is designed to ease Prowler maintenance in a lighter, more reliable, and lower cost enclosure for NAVAIR, company officials say.

ISR is the prime contractor for this contract under ISR's $35 million SBIR Phase III contract vehicle (issued out of Navair). The U.S. Navy, Naval Systems Warfare Center Crane division in Crane, Ind., is providing technical oversight for the program as well as reliability assessments for SprayCool systems and electronics.

SprayCool technology is already deployed on the U.S. Marine Corps Advanced Amphibious Assault Vehicle (AAAV) and because of the successful EA-6B Prowler test is being looked at for use on unmanned aerial vehicles, company officials say.

For more information on ISR or SprayCool technology go online at www.spraycool.com.