Mill-Max receptacles enable replacement or upgrade of keyboard switches and other circuit board components

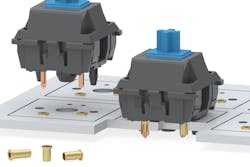

OYSTER BAY, N.Y. – Mill-Max Manufacturing Co. in Oyster Bay, N.Y., is introducing the 3305-X series of open-bottom, low-profile solder-mount receptacles to make mechanical keyboard switches hot-swappable.

The 3305-X can be soldered into a .060-inch minimum mounting hole, with an ultra-thin retention shoulder so plugged-in components sit nearly flush to the keyboard surface.

The 3305-X series offers three length options of 0.105, 0.130”, and .155 inches, all with an above-board height of .010-inches. The 3305-X series uses a beryllium copper contact clip to make dependable low-resistance connections with mated leads that last for thousands of cycles.

The 3305-X accepts round leads of 0.025, 0.037, and 0,635 inches in diameter as well as square and rectangular leads of 0.019 to 0.026 inches square, which are typical of the leads found on most keyboard switches.

Related: Solderless press-fit receptacles for circuit board interconnects introduced by Mill-Max

The introduction of the 3305-X series and this style of receptacle means that repair, upgrade, or making custom keyboards -- once tedious and time-consuming endeavors -- have become viable options by eliminating the painstaking task of de-soldering then re-soldering an entire keyboard.

Conversely, after the one-time process of installing Mill-Max 3305-X receptacles, all the key switches can be replaced in just a few minutes to enable users of all skill levels to join the hot-swap keyboard movement.

For more information contact Mill-Max online at www.mill-max.com/PR701.