Rugged connector for cable terminations and heavy-duty quick connects introduced by Mill-Max

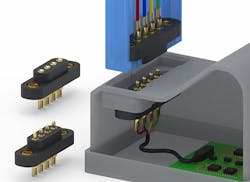

OYSTER BAY, N.Y. – Mill-Max Manufacturing Co. in Oyster Bay, N.Y., is introducing the 868 series rugged 4-millimeter-pitch connector with wire termination spring-loaded and target connectors for mounting into product housings for docking stations, cable terminations, heavy-duty quick connects, and panel mount equipment.

The 868 connectors include solder-cups to accommodate wire and cable attachment along with flanged insulators and fastening options. They are for wire termination, with uniformly aligned solder-cup pins to facilitate efficient soldering of wires as thick as 16 AWG.

The 868-22-00X-00-0X1101 spring-loaded connectors have heavy-duty spring pins with 0.05-inch-diameter plungers that resist bending and binding during the application of side loads. The gold-plated stainless-steel spring on the connector ensures reliable operation to 1 million cycles and is less prone to stress relaxation when operating at high temperatures over time (to 260 degrees Celsius for one hour, to 180 C for 24 hours).

Each spring pin is rated for 9 amps at a 10 C temperature rise with a contact resistance of less than 20 micro-Ohms and provides as much as .09 inches of stroke.

The 868-10-00X-00-0X1000 target connectors come either in a flat or concave face on the mating side of the pins. The flat face style is 0.082 inches in diameter providing ample target area for the 0.05-inch diameter rugged mating plunger.

Concave face targets provide additional surface area when mated and can aid in centering/alignment of components fitted with spring loaded connectors during manual engagement.

Available in two to six positions, the 868 series connectors have high-temperature molded Nylon 46 insulators compatible with RoHS soldering processes. Mounting tabs, integrated into the insulators, provide a means for secure attachment to product housings or circuit boards.

The tab holes may be specified with threaded inserts or left empty for other hardware requirements. Gold plated, precision machined brass components ensure high conductivity, corrosion resistance, and durability.

For more information contact Mill-Max online at www.mill-max.com/PR688.

Ready to make a purchase? Search the Military & Aerospace Electronics Buyer's Guide for companies, new products, press releases, and videos