Pressure transmitter sensors for real-time demanding industrial diagnostics introduced by Emerson

Summary points:

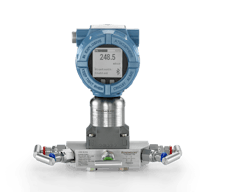

- Emerson introduces the Rosemount 4051S pressure transmitter for real-time local control in demanding industrial environments to reduce the need for separate controllers.

- Built-in diagnostics and process intelligence detect potential failures, plugged lines, and abnormal conditions to enhance reliability and maintenance efficiency.

- Fast response and flexible operation, with a 40-millisecond response time, 800:1 turndown ratio, and an upgraded multilingual display for easier on-site use.

SHAKOPEE, Minn. – Emerson Electric Co. in Shakopee, Minn., is introducing the Rosemount 4051S pressure transmitter for demanding pressure measurement in industrial applications.

This pressure transmitter can provide local real-time control to eliminate the need for a separate programmable logic controller. It uses two relay switches, each configurable to provide on/off control of pumps, motors, and other equipment.

These switches also can provide alerts based on pressure, flow, totalized flow, level, volume, or module temperature.

Engineered to withstand tough processes and environments. These pressure sensors offers response time of 40 milliseconds and an 800:1 turndown ratio to reduce the number of unique models.

Advanced diagnostics

Advanced diagnostics provide more insights, with loop integrity that continuously monitors the health of the electrical loop to detect potential failures.

Plugged impulse line detection alerts plant personnel so they can take action, and the transmitter also can diagnose other abnormal conditions like cavitation by using its built-in process intelligence. Built-in calibration and diagnostic logs provide the information needed to optimize maintenance and perform root cause analysis.

The graphical, backlit display is larger than previous models, making it easier to read and allowing inclusion of more descriptive warning messages, an always-on process variable value, and a customizable secondary area. The display can be configured in seven languages, and the intuitive user interface speeds and simplifies operator interactions, while reducing the risk of errors.

For more information contact Emerson online at www.emerson.com/en-us/automation/measurement-instrumentation/pressure-measurement/pressure-measurement-innovations.

About the Author

John Keller

Editor-in-Chief

John Keller is the Editor-in-Chief, Military & Aerospace Electronics Magazine--provides extensive coverage and analysis of enabling electronics and optoelectronic technologies in military, space and commercial aviation applications. John has been a member of the Military & Aerospace Electronics staff since 1989 and chief editor since 1995.