Flight Display Systems’ Woodall: Ruggedization an important consideration, common requirement for airborne displays, especially in smaller cockpits

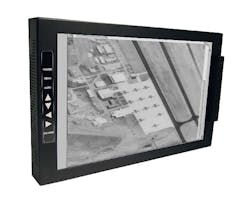

Flight Display Systems engineers have been producing special mission aircraft components for five years, and are currently working on a new night-vision/sunlight-readable project for smaller cockpit liquid crystal displays (LCDs).

When it comes to ruggedized products, “it’s not just about beefing stuff up,” admits Josh Woodall, Flight Display Systems’ customer support lead and an ex-Air Force C-12 Reconnaissance operator. “Weight is a huge concern. It has to be designed to work well on lightweight products.

“The newest version of our military spec arm has great potential,” Woodall adds. “The problem with special missions is that, in the last five years or so, airborne law enforcement and military reconnaissance have moved to very small, lightweight aircraft. On those, a 15-pound piece of hardware is something you have to really consider. A seven-pound part is really going to catch [people’s attention]. Flight Display Systems products are getting better every day, and we are using the latest technology to get there.” The company’s LCD aircraft monitors consist, in part, of an LCD and a polycarbonate protective sheet, which is secured to the LCD with an open cell foam gasket. No gas is introduced or maintained between the LCD and the polycarbonate. The majority of the company’s LCD monitors have similar construction using the same cold-cathode fluorescent lamp (CCFL) technology.Flight Display Systems’ engineers use GE LEXAN 9600 as a cover to the LCD on the company’s monitors. The thickness for 20-inch monitors or smaller is .060 inch; for 26-inch monitors or larger, it is .125 inch. The material has a VTT3060 antiglare chemical and abrasion-resistant hard coat on the front surface and it covers the entire screen. LEXAN 9600 sheet offers improved flammability and heat-deflection characteristics over the standard polycarbonate sheet. It meets industry flammability codes, including the standards of UL Bulletin, Class I and FAR25.853A,B. Flight Display Systems monitors are engineered and built in-house to customer specifications and tested in various scenarios. In fact, the company has had several LCD monitors tested for rapid decompression, ball strike, flammability, stress, vibration, and the like, according to airborne DO-160 requirements.

Follow Avionics Intelligence news updates on Twitter (@Avionics_Intel), LinkedIn, and Google+.