High-performance systems harness the power of microprocessors

Aerospace and defense professionals, in the quest to do more with less, have turned attentions to infusing systems new and old with robust, capable, and efficient military microprocessors. A wealth of high-performance embedded computing (HPEC) options exist, however, causing systems architects and systems integrators to take pause and closely consider all alternatives when selecting silicon.

A set of characteristics is fairly common across most aerospace and defense embedded computing applications, whether an airborne platform, tactical radio, radar, or munition; yet, the value, or priority, of these characteristics can vary significantly depending on the application, explains Jason Moore, director of aerospace and defense applications engineering at Xilinx Inc. in San Jose, Calif., which specializes in field-programmable gate arrays (FPGAs).

Performance--including throughput, interrupt latency, as well as cache size and speeds--is an important consideration in military embedded systems, as is the board support package (BSP) for real-time operating systems (RTOSs) and device drivers (e.g., a DO-178B RTOS for avionics applications), Moore says. Memory and I/O interfaces, cost, and anti-tamper and physical security characteristics should also be considered: “Can the processor be booted securely? Does it provide adequate protection of the IP or data it is operating on?” he questions.

“It is important to differentiate between dynamic power and static power when considering power consumption,” Moore continues. “Dynamic power is a serious consideration in high-performance systems, such as large radar arrays, where there are concerns with how to get the heat out/cool the system. Static power and sleep modes are also critical in military communications, like tactical radios, where battery life is critical.

“Maintaining the integrity of the data, through the use of technology, such as error-correcting code (ECC) or processor lockstep operation, throughout the processing subsystem is important across many applications such as avionics and military communications,” Moore admits.

COTS computing

Microprocessors for military and aerospace applications are following the same vector as those used in the broader commercial market, recognizes Rod Rice, general manager of Military & Aerospace Products at GE Intelligent Platforms in Charlottesville, Va. The proliferation of commercial off-the-shelf (COTS) solutions which leverage commercial technologies reduce cost and development time, while increasing performance and providing regular technology insertion opportunities, long-term support roadmaps, and overall lower cost of ownership, he says.

“The impact of this can be clearly seen in the offerings from companies like Intel,” Rice says, recalling that the second generation of Intel Core processors was announced roughly one year ago. “The next generation will be with us shortly with, it is reported, a smaller die size and an increased number of transistors that will provide another uptick in performance. These will be incorporated into mil-aero board level products in the coming months.”

Mil-aero applications are increasingly favoring multi-core microprocessors, allowing for greater processing capacity, Rice adds. “As well as Intel’s multi-core offerings, Freescale -- the other significant microprocessor supplier to the mil-aero market -- provides solutions, such as the QoriQ P4080 with its eight processors.”

The ability to use several processors within one piece of silicon has given rise to the growing adoption of technologies that use massively parallel architectures, including graphics processing unit (GPU) technology such as CUDA from Nvidia in Palo Alto, Calif., Rice observes. General-purpose computing using general-purpose GPUs (GPGPUs) is enabling significant performance increases in mil-aero applications that can leverage that parallelism, such as radar, in which increased throughput on the order of 15X has been demonstrated in comparison with more traditional processor approaches.

“Another key requirement, given the space constraints under which many mil-aero programs are deployed, is a higher degree of silicon integration that allows for either smaller form factor (SFF) boards or higher functional density on a single board,” Rice says. Integration of graphics capability, for example, within the processor is highly desirable; moreover, he adds, as mil-aero applications become increasingly graphics-intensive, focus is on the quality of integrated graphics.

Increased imagery

Kevin Berce, defense manager at Nvidia, is seeing a dramatic increase in demand for Nvidia Tesla GPUs in the defense market. Three application areas, in particular, are growing the fastest: image processing, signal processing, and data analytics. “MotionDSP is a great example of the benefit of GPU acceleration in the image processing space,” he says.

“Each of these examples requires significant processing power that cannot be achieved easily or cost-effectively with CPU-only systems,” Berce says. “In some cases, CPUs simply cannot provide enough processing power to process the data fast enough to deliver actionable information or intelligence.” For example, to process a single hour of UAV video with Ikena ISR typically takes four to six hours on a CPU-based system; yet, a hybrid system combining a CPU and GPU can process the same hour of video in real time.

“Due to the highly parallel architecture of GPUs, they can provide an order of magnitude greater performance than CPUs, and can easily accelerate applications to give the military invaluable data immediately,” Berce notes.

The benefits of GPUs go beyond application acceleration, extending to space, power, and cost savings. “GPUs allow government customers to save money on compute resources, without compromising on performance,” Berce explains. Solers Inc., a provider of information technology solutions to government customers, was able to eliminate 20 blades (from 68 to 48) by adding six GPUs to its Dell server. By introducing GPUs into its Dell system, Solers was able to reduce the footprint by 30 percent and power consumption by about 27 percent, while also delivering greater performance by reducing processing latency by 25 percent, he says.

Nvidia’s GPUs are actively being adopted in aerospace and defense data centers as well as in electronics systems on the battlefield. Its Tesla brand GPUs are designed to meet computational requirements in data centers and high-performance computing environments, as well as to deliver significant performance increases for a variety of other applications used by government customers, including computational fluid dynamics, video processing, synthetic aperture radar (SAR), and electromagnetics. “GPUs are being deployed by key computer original equipment manufacturers (OEMs), as well as by several partners offering embedded solutions, such as GE Intelligence Platforms and Curtiss-Wright.

Microprocessors, and GPUs specifically, have a bright future in the mil-aero arena, Berce adds. “GPUs will continue improve the performance per watt, outpacing the advantages of a CPU-only system. As a result, GPUs will drive a new generation of applications that deliver better, more accurate information quickly with much higher fidelity.”

Military vs. COTS

The requirements for aerospace and defense microprocessors differ somewhat from their commercial counterparts in key areas, says Rice. “The provision of a floating-point processor -- AVX in Intel’s case, and AltiVec from Freescale -- is important for demanding digital signal processing (DSP) applications.

“As significant processing power is increasingly deployed within environments that are highly space- and power-constrained, low power consumption--with its associated reduced cooling requirement--is a key characteristic. Many mil-aero applications have begun to focus more on performance/watt rather than pure performance,” Rice adds.

“The majority of mil-aero applications are deployed in harsh environments that are subject to shock, vibration, moisture, dust, and so on,” Rice says. “While this does not place specific requirements on the processor itself, it must be capable of being integrated on a rugged board designed to withstand the rigors of military deployment.

“The typical mil-aero program can be deployed over years, and even decades. This generates a requirement for long-term availability of components, and long-term support for those components, as well as a requirement for form/fit/function-compatible upgrades over time to allow for technology insertion, increasing performance while maximizing long-term cost of ownership,” Rice continues. GE offers products that enable customers to choose the appropriate trade-off between processing capacity and power consumption/heat dissipation, as well as ruggedization technologies and processes for deployment in harsh environments, Rice says. Regular, compatible upgrades within each product family enable customers to insert new technology, while Product Lifecycle Management capability helps maximize value over the extended deployment lifetimes typical of mil-aero applications, he explains.

“While performance and low power consumption will always be key considerations for prime contractors and OEMs in choosing a single-board computer, the guarantee of long term availability over an extended period is no less important,” Rice acknowledges.

Engineers at Harris Corp.’s Government Communications Systems Division (GCSD) in Melbourne, Fla., understand well the importance of long-term support and the provision of regular technology insertion opportunities. Harris officials first selected GE’s PPC7E single-board computer in 1999 for the high-mobility artillery rocket system (HIMARS), the newest member of the multiple-launch rocket system (MLRS) family; more than a decade later, GE continues to provide the board.

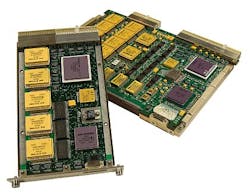

GE Intelligent Platforms continues to secure orders from Harris for PPC7EP single-board computers; the latest in a series of orders placed by Harris for the MLRS program over 12-plus years is a roughly $3.5 million order placed in Nov. 2011. Lockheed Martin engineers subcontracted Harris to design and build the electronics for the US Army’s MLRS M-270 HIMARS platform. The PPC7EP executive processor is a custom variant of GE’s PPC7D, a 6U VME single-board computer featuring the 7448 PowerPC processor. Three PPC7EPs, one with a PMCGA4C graphics accelerator card, are deployed in each vehicle and provide the key computing power for HIMARS subsystems.

“MLRS/HIMARS is an outstanding example of a long-term program that relies on the continuing availability of critical components, the extended support–such as obsolescence management -- necessary to ensure success and the opportunity for ongoing technology insertion,” says Al DiLibero, president, Military & Aerospace Embedded Computing, GE Intelligent Platforms.

Computational communications

Just as microprocessors benefit from the power inherent in GPUs, they are likewise aided in aerospace and defense applications by robust field-programmable gate arrays (FPGAs). In fact, Xilinx has more than 10 years of integrated processor experience delivering embedded processing solutions -- dating back to the Virtex II-Pro, Virtex-4, and Virtex-5 PPC-based FX platforms -- for a variety of aerospace and defense applications, including: missiles and munitions, for target tracking; military communications, for black-side modem operations and red-side key management and user interface; and electronic warfare/intelligence, surveillance, and reconnaissance (EW/ISR), such as radar algorithm processing.

“Software-defined radio (SDR) platforms classically consist of a general-purpose processor (usually ARM) and FPGA for user interface and baseband signal processing respectively,” Moore says. “The large interest in Zynq for SDR is not just about integrating the classic SDR baseband functions to reduce size and power, it is also about increased system performance and decreased development effort. The Zynq platform is an ideal integration of standard SDR devices with the dual ARM Cortex-A9 processors and device family with a range of progressively richer programmable logic (PL) resources.”

The Zynq ARM cores are tightly coupled to all peripherals (hardened I/O, DDR, and logic) by the AMBA AXI-4 interconnect fabric, which also connects the programmable logic to all these subsystems, Moore explains. “It is the AXI fabric that allows high-throughput, low-latency, standards-based interconnect of custom logic for modem, cryptographic, and other hardware-in-the-loop logic to the ARM cores, hardened I/O, and DDR,” Moore explains. The advantage in lower development time and faster throughput over a separate ARM + FPGA devices is substantial.”

Airborne application

A broad range of aerospace and defense applications and platforms require rugged microprocessors; this is especially true of airborne and land-based combat vehicles. “Kontron specializes in military environments that demand extreme ruggedization,” says David O’Mara, product manager at Kontron in Poway, Calif. In fact, one of its standard products is employed onboard the Apache Helicopter.

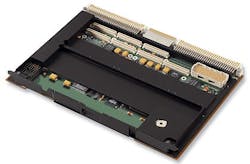

The Apache helicopter application employs COBALT -- a small, lightweight computing device based on Kontron’s COM Express single-board computer that offers fanless operation and an integral Gigabit Ethernet interface -- with an onboard 8-port GigE switch (five ports to the outside world), along with an 80-gigabyte solid-state drive and a Kontron Core2Duo single-board computer for the computing function.

O’Mara and his Kontron colleagues see a growing demand for optimized SWAP-C products. “The UAV market is growing rapidly (along with other unmanned applications) and the need for small, lightweight, fanless products will drive the development of microprocessors over the next several decades,” O’Mara affirms. “Although SWAP-C and product life cycle are top priorities, numerous successes in the field are made possible by a solid computer health management and logistics support infrastructure.”

Kontron is, as a result, concentrating on power-on built-in test (PBIT) and computer management board (CMB) innovations, which can be lifesavers when computer systems are deployed. “All these low level features, often hidden from the casual observer, make the difference in the end,” O’Mara observes. “Today, it seems that a lot of companies can design computer boards, but only a handful of them have enough field expertise to grasp the importance of this in mil-aero computer systems.”

Safe in space

Space, among the harshest environments for electronics, requires rugged, radiation-hardened processors. BAE Systems has, since the 1990s, been designing, building, and delivering radiation-hardened (rad-hard) processors via its rad-hard foundry in Manassas, Va., says Victor Scuderi, manager, Satellite Electronics, BAE Systems. “We develop the rad-hard processor chips, then design the single-board computer to use these processors.”

The first-generation, single-board computer was a rad-hard version of a MIL-STD 1750 processor; followed by the RAD6000, a rad-hard version of an IBM RISC System 6000 processor. The current-generation RAD750, a rad-hard version of an IBM PowerPC 750 processor, is adopted for satellite single-board computers serving command and control functions and onboard payload processing. The Advanced Extremely High Frequency satellite, a U.S. Department of Defense (DOD) secured communications satellite, uses two RAD6000 computers for satellite control and eight RAD750 computers for the payload.

BAE Systems engineers measure flight heritage by tracking “on-orbit” or “in space” time for its computers. “There are currently 625 BAE Systems single-board computers used on 200+ satellites that have been launched since 1995,” Scuderi explains. “More specifically, we track every hour each of our computers has been in space. The three generations of BAE Systems computers have amassed an aggregate of 50,413,800 hours or 5,755 years in space -- a direct measure of the effectiveness of the people, tools, and processes used to design, build, and test these products.”

Scuderi sees demand for very high-performance satellite payload processing solutions, the requirements of which also drive high-performance I/O and network capabilities. “This new market will require a collection of technology products, such as: high-density FPGAs, digital signal processors (DSPs), and multi-core, general-purpose processors. High-density ASICs will still be required to meet specialized functions and address power constraints,” he says. “For each of these technology products, leveraging commercial intellectual property and enhancing it to meet the rigors of the space environment will continue to be a core element of our approach to meeting customer requirements.”

Future functionality

The coming months, years, and decades will, no doubt, bring new applications and new computing challenges requiring increasingly robust, efficient, and capable microprocessor technology.

“Microprocessors will become increasingly capable--not only delivering more throughput, but also integrating increased functionality--allowing for the greater functional density that will permit the deployment of highly sophisticated, demanding applications in smaller spaces,” GE’s Rice predicts.

“There will continue to be focus on minimizing power consumption/heat dissipation. Multicore processors will continue to gain market share, with the number of processors per piece of silicon increasing,” Rice adds. “The adoption of GPGPU technology will also continue.”