AIT conformal coatings designed to protect electronics in extreme environments

Critical infrastructures, such as electrical power stations, need protection against corrosion in high voltage contact points. Electrical switches and other controlling electronics in industrial environments require protective coatings that can withstand direct water immersion and "acid rain" induced degradation. Additionally, outdoor electronics require extended moisture protection during the heat and humidity of summer weather.

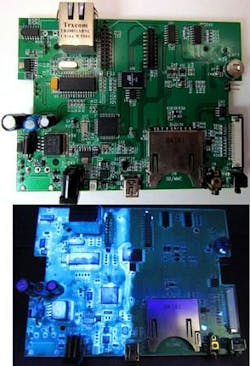

Responding to the pervasive need for conformal coatings, AIT has unveiled its improved Prima Protect coating line for moisture and salt fog protection.

Two chief Prima Protect Coatings--CC7090E and CC7130-E--offer extreme moisture, salt fog, and even direct immersion protection for electrical contacts, electronic circuits and devices, printed wiring boards, and structures made with metal, wood, and plastics. AIT’s Prima Protect coatings are molecularly flexible for adhesion, yet they resist abrasion.

AIT’s coatings have added flexibility to withstand low-temperature cracking, fungicide to provide additional protection in submerged environments, and are non-silicone and electrically insulating so to not interfere with neighboring electronics.

Both CC7090E and CC7130-E are designed to meet the IPC CC830 requirements with UV inspection dye and fungi-resistance. Additionally, both coatings can be brushed, dipped, or sprayed on and are flexible, highly hydrophobic and provide superior protection against corrosion in water, salt water, fog, and many other types of environments.

AIT’s Prima Protect Coatings work on virtually any surface, officials say, and are used to coat outdoor equipment, batteries, and wiring.