Mentor Graphics enhances MicReD industrial power tester with 4X component power cycling, thermal testing

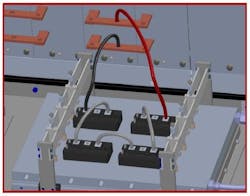

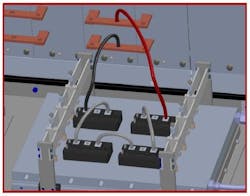

WILSONVILLE, Ore., 12 May 2015.Mentor Graphics Corp.’s (NASDAQ:MENT) next-generation MicReD Industrial Power Tester 1500A product, which provides electronics components power cycling and thermal testing for up to 12 devices simultaneously.

“Advanced thermal management is crucial for the design of power modules and power electronics packages,” says Chang-Sheng Chen, manager, power devices packaging technology department, advanced package technology division, Electronics and Opto-Electronics Research Laboratories at the Industrial Technology Research Institute (ITRI). “Our partners use thinner and thermally more conductive TIMs, new substrate materials, and new interconnect technologies to decrease thermal resistance and increase the lifetime of their products.

“Power cycling tests are required to gather information about the lifetime and possible failure modes of these new devices; however, in order to have reliable data, statistical analysis is important. The new MicReD Power Tester 1500A with 12 channels can increase the throughput of our power tester by four times, allowing us to finish our projects significantly faster,” Chen adds.

The MicReD Industrial Power Tester 1500A commercially available thermal testing product combines power cycling and thermal transient structure function analysis for real-time, failure-in-progress data for diagnostics. Based on market feedback and the success of the MicReD Power Tester 1500A three-channel product, Mentor Graphics engineers have enhanced the product to accommodate more device testing for greater productivity and lifecycle performance, benefitting power generation and converters, renewable energy products, and more, officials explain.

The MicReD Industrial Power Tester 1500A can perform power cycling tests of metal-oxide semiconductor field-effect transistors (MOSFETs), insulated-gate bipolar transistors (IGBTs), and power diodes. Both power cycling and thermal transient measurements are conducted without needing to remove the components from the test environment.

Measurements of both top and bottom transistors in half-bridge structures can be achieved at the same time. The MicReD Power Tester 1500A provides a user-friendly touch-screen interface and can record a broad range of information during test, such as current, voltage, and die temperature sensing, as well as detailed structure function analysis to record changes in the package’s thermal structure. A technician or engineer is able to see the failure as it progresses and determine the exact time/cycle and cause. This makes it an ideal platform for package development and quality checking of incoming parts before production.

“Knowing that their electronic components will perform to optimum standards is crucial for their success,” Roland Feldhinkel, general manager, mechanical analysis division at Mentor Graphics, says of customers. “Using the MicReD Power Tester gives our customers added confidence by helping them develop and validate both electronic parts and batches of parts for manufacturing with greater performance reliability.”

Mentor Graphics Corp. (NASDAQ:MENT) is a provider of electronic hardware and software design solutions, providing products, consulting services, and award-winning support for electronics and semiconductor companies.