Composite companies partner to enable fast aircraft MRO services

PARIS, June 2015. As more and more composite-intensive aircraft enter service around the world, there is an increasing requirement for airlines to carry out composite repair operations. Repairing aircraft quickly to minimize downtime means that small quantities of materials have to be readily available at all times. Hexcel’s stand at Le Bourget (Stand Hall 2B, F80; Chalet B113) is co-located with Groupe Gazechim Composites, an official distributor of Hexcel products, and affiliate Composites Distribution.

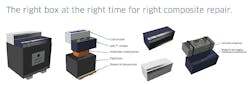

Hexcel and Composites Distribution are partnering to provide solutions for maintenance, repair, and overhaul (MRO) that allow aircraft repairs to be carried out quickly and conveniently. Composites Distribution is launching the new CAB concept (Composite AeroBox) from Sunaero. This tool kit has different compartments for the storage of frozen prepregs, ancillary materials that are kept at ambient temperature and a hotbonder control panel, all contained within an easy to transport box that holds everything required for a quick repair of a composite part in the field.

Hexcel’s range of products developed for composite repair includes HexPly M20 prepreg and HexForce carbon fabrics. HexPly M20 prepreg provides high temperature performance from a low energy cure cycle at 120-130°C (250-265°F) and can be processed in the field using vacuum bag and a heater blanket or hot bonder or in an autoclave. These materials are approved by the CACRC which sets global aerospace standards for composite repair operations.

Hexcel’s new RTM resin, HexFlow RTM230 ST, performs at high temperatures with superior toughness and has excellent high-rate impact resistance, officials say. The resin combines high in-plane and impact performance with good long term thermal stability, making it particularly suitable for engine components such as fan blades and cases, spacers and outlet guide vanes. HexFlow RTM230 ST is also easy to process thanks to a 45-minute injection window. In addition, the system demonstrates outstanding resistance to aggressive fluids including commonly used solvents and aviation fuel.

Hexcel also is promoting HexPly M92, the latest generation 125°C curing prepreg that combines superior hot wet performance up to 115°C, self-adhesion, high toughness, fire-resistance, low exotherm and a long out/tack life. On display will be a wing fuselage fairing door demonstrator manufactured by Embraer (shown right) using HexPly M92 carbon fiber prepreg. This honeycomb sandwich structure requires no adhesive thanks to the self-adhesive properties of HexPly M92.

HexPly M91 is a new high toughness and impact-resistant epoxy prepreg from Hexcel that is used by Rolls-Royce to manufacture CTi fan blades for new generation lightweight turbofan engines. Hexcel supplies HexPly M91 as slit tape for the automated lay-up of the complex aerodynamic shape, with a constantly changing thickness across the blade length. The blade which is thinner and lighter than titanium fan blades is currently undergoing flight tests. Rolls-Royce has loaned Hexcel a CTi fan blade to display at the air show.

Hexcel has also been supporting Rolls-Royce with materials for the low weight containment case that will house the new fan blades. The casing developments use Hexcel’s Intermediate modulus carbon fiber along with a Hexcel out of autoclave resin system. This extensive use of composite materials in the containment case design saves weight and enhances efficiency for next generation engines.

Since Hexcel launched HexTow HM63 carbon fiber last year, this high modulus fiber has been quickly adopted by customers and is already in multi-lot qualification with major space and aerospace OEMs. HexTow HM63 has high tensile strength and provides outstanding translation of fiber properties in a composite, including superior interlaminar shear and compression shear strength.

On the Hexcel stand at Le Bourget, visitors can see an out-of-autoclave filament wound carbon composite structure manufactured by Airbus Defence and Space using Hexcel’s HexPly M56 and HexTow HM63 carbon fiber towpreg. The part was manufactured in a partnership framework to develop high performance towpreg for space applications.

Hexcel’s HiTape advanced dry carbon fiber reinforcements are designed for the automated manufacture of preforms at very high deposition rates. The preforms are then infused with Hexcel’s RTM6 resin in a cost-efficient, out-of-autoclave process. Parts produced with HiTape reinforcements and Hexcel’s HexFlow® infusion resins can be up to 30mm thick with 58% to 60% fiber volume content, resulting in mechanical properties that are as high as those achieved with primary structure prepregs.

Hexcel partnered with Stelia Aerospace (formerly Aerolia), Coriolis Composites, and CompositeAdour to collaborate on the design, manufacture, and testing of a primary aircraft structure – a self-stiffened fuselage demonstrator panel - using HiTape. The resulting panel that is displayed at Le Bourget demonstrates that HiTape meets the aerospace performance standards for primary structures, including damage tolerance. This cost–and-cycle efficient technology meets the targets for next generation aircraft.

Hexcel Corporation, an advanced composites company, develops, manufactures, and markets lightweight, high-performance structural materials, including carbon fibers, reinforcements, prepregs, honeycomb, matrix systems, adhesives, and composite structures used in commercial aerospace, space, and defense applications.