NASA’s New Horizons space exploration mission benefits from Microsemi FPGAs, power supplies, electromechanical relays

ALISO VIEJO, Calif., 2 Sept. 2015. High-reliability power supplies, electromechanical latching relays, several JANS class diode and transistor discrete devices, and RTSX-SU field programmable gate arrays (FPGAs) from Microsemi Corp. (Nasdaq:MSCC) are used in imaging cameras onboard NASA’s New Horizons spacecraft supporting its exploration mission to Pluto. Microsemi’s space solutions are which are used in imaging cameras providing remarkable high-resolution images of Pluto, as well as in the communications systems and other avionics and payload systems.

The FPGAs onboard NASA’s Pluto New Horizons spacecraft are radiation-hardened by design and have been used in missions to the moon, Mars, Venus, the outer planets, and in many earth-orbiting satellites.

“Microsemi is honored that NASA selected our high-reliability products once again for the Pluto New Horizons spacecraft exploration mission,” says James J. Peterson, chairman and CEO of Microsemi. “This historic mission is yet another milestone in space exploration. Our technology played a crucial role in this significant event, and we look forward to our continued commitment to supporting the most demanding space missions and development programs around the world with our highly specialized solutions.”

Microsemi’s space product portfolio features radiation-tolerant and radiation-hardened (rad-hard) components for demanding space applications. With solutions specifically designed for deep space and harsh conditions, Microsemi’s FPGAs mitigate radiation effects.

Microsemi’s space heritage began in 1957 when its micro-positioner relay was launched in the Atlas rocket. The company’s space technology was subsequently deployed in a variety of space missions in the 1950s and 1960s, as well as in the Surveyor, Apollo, and Saturn programs of the late 1960s and 1970s, the international space station program initiated during the 1990s, and the Mars Rover, Mars Science Lab and Cygnus spacecraft initiatives of the 2000s and 2010s. Microsemi also powered the mission computer on the Near Earth Asteroid Rendezvous (NEAR) Shoemaker Satellite during its five-year mission and ultimate landing on the surface of Eros, as well as the 10-year-long Rosetta spacecraft mission to examine Comet 67P/Churyumov-Gerasimenko.

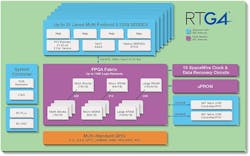

Microsemi recently announced its new LX7730 radiation-tolerant telemetry controller IC providing key functions for sensor monitoring, attitude and payload control, as well as its RTG4 high-speed signal processing radiation-tolerant FPGA family.

The RTG4’s reprogrammable flash technology offers complete immunity to radiation-induced configuration upsets in the harshest radiation environments, requiring no configuration scrubbing, unlike SRAM FPGA technology.

Microsemi Corp. (Nasdaq:MSCC) offers a portfolio of semiconductor and system solutions for communications, defense & security, aerospace, and industrial markets. Products include high-performance and radiation-hardened analog mixed-signal integrated circuits, FPGAs, SoCs and ASICs; power management products; timing and synchronization devices and precise time solutions, setting the world’s standard for time; voice processing devices; RF solutions; discrete components; security technologies and scalable anti-tamper products; Ethernet solutions; Power-over-Ethernet ICs and midspans; as well as custom design capabilities and services. Microsemi is headquartered in Aliso Viejo, Calif., and has approximately 3,600 employees globally.