MIT tests, issues first commercial production order for SPAR tiles for radar to benefit FAA, NOAA

LOWELL, Mass., 11 Nov. 2015. Engineers at the Massachusetts Institute of Technology (MIT) Lincoln Laboratory working on Multifunction Phased Array Radar (MPAR) technology needed radio-frequency (RF) assemblies for the radar system’s planar active electronically scanned array (AESA) antenna. They found their solution at M/A-COM Technology Solutions Inc. (MACOM; NASDAQ:MTSI), a supplier of high-performance analog radio-frequency (RF), microwave, millimeterwave, and photonic semiconductor products in Lowell, Mass.

MPAR technology is the foundation for the next generation of civil radar networks, integrating eight separate legacy radar functions into a single multifunction platform. MPAR-based systems can increase forecast accuracy for severe weather events, such as tornadoes and facilitate earlier major storm warnings, as well as support air traffic control (ATC) functionality. The current air traffic control network, built over 30 years ago, is approaching obsolescence; upgrading to MPAR-based systems will provide improved awareness in air traffic patterns, increasing safety and flight efficiencies.

Developed by MIT Lincoln Laboratory under sponsorship of the Federal Aviation Administration (FAA) and National Oceanic and Atmospheric Administration (NOAA), the MPAR system leverages an array of MACOM-manufactured phased array tiles to transmit and receive pulses of radar energy to detect and track weather systems, while simultaneously providing civil air surveillance.

“MPAR technology holds great promise for weather and civil aviation radar applications, and will ultimately improve the safety and security of citizens across the nation,” explains Jeff Herd, group leader for RF technology, MIT Lincoln Laboratory. “The successful MPAR field testing is an important step forward in demonstrating the commercial and functional viability of this sophisticated technology.”

MIT engineers ordered MACOM Scalable Planar ARray (SPAR) Tiles for use in the first full-scale MPAR system following successful field trials of the MPAR prototype system. The field test demonstrated “the maturity of the technology and the manufacturing processes that underpin it,” says Dr. Doug Carlson, vice president of strategy, MACOM. “The next step is to move to volume commercial manufacturing that can support the scale of production of civil and defense deployments in the field.”

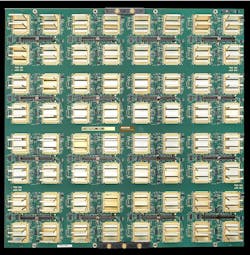

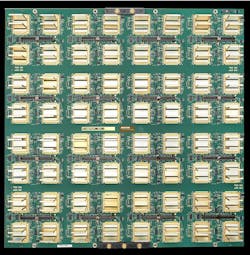

SPAR Tiles are RF assemblies containing antenna elements, GaAs and GaN semiconductors, transmit and receive modules, and RF and power distribution networks. When combined with additional signal generation and receive and control electronics, the composite assembly forms the building block for the MPAR planar active electronically scanned antenna (AESA) for the radar system. SPAR Tiles enable the transition from cumbersome traditional brick architectures to a more efficient planar approach, officials say.

The MPAR radar system enables enhanced temporal and spatial precision for weather surveillance and air traffic control applications. It is anticipated that the government proof-of-concept system will demonstrate a unique radar capability that simultaneously improves both aircraft and weather surveillance.

“The implementation of MACOM’s SPAR Tiles as a critical element of a full-scale demonstration of MPAR represents a major milestone in the validation of this new approach for manufacturing AESAs,” Dr. Carlson adds. “SPAR Tiles enable new levels of affordability and flexibility across a broad range of civil and defense applications. Our ability to fulfill large orders of SPAR Tiles demonstrates the scalability of our manufacturing approach to achieve volume production of this highly integrated and complex RF product.”

M/A-COM Technology Solutions Holdings Inc. (www.macom.com) is a supplier of high-performance analog RF, microwave, millimeterwave, and photonic semiconductor products that enable next-generation Internet and modern battlefield applications. MACOM serves diverse markets, including high-speed optical, satellite, radar, wired and wireless networks, automotive, industrial, medical, and mobile devices. Headquartered in Lowell, Massachusetts, MACOM is certified to the ISO9001 international quality standard and ISO14001 environmental management standard. MACOM has design centers and sales offices throughout North America, Europe, Asia, and Australia.

You might also like:

Subscribe today to receive all the latest aerospace technology and engineering news, delivered directly to your e-mail inbox twice a week (Tuesdays and Thursdays). Sign upfor your free subscription to the Intelligent Inbox e-newsletter at http://www.intelligent-aerospace.com/subscribe.html.

Connect with Intelligent Aerospace on social media: Twitter (@IntelligentAero), LinkedIn,Google+, and Instagram.