Airbus uses IoT to fuel ‘Factory of the Future’

By Jon Marcus

The multibillion-dollar European aircraft maker, which controls half the worldwide commercial airplane market, is applying Internet of Things technology not only to its products, but to the tools its workers use in the manufacturing process to do such things as drive thousands upon thousands of bolts.

Unlike auto plants, airplane assembly lines have not historically widely used robots in their precision manufacturing. Instead, humans are in charge, assisted by robotic tools.

By connecting both the people and those tools to an IoT platform, said Jean-Bernard Hentz, Head of PLM R&T & Innovation at Airbus ICT, manufacturing speeds up.

“We need simple solutions,” Hentz told an audience at LiveWorx. This has led to what Hentz called Rosie the Riveter 2.0: an Airbus worker on the factory floor who can use a tablet or smart glasses to scan an airplane’s metal skin and determine what size bolt is needed in a given hole, and the torque required to install it. That information can be spontaneously sent to a robotic tool, which completes the task.

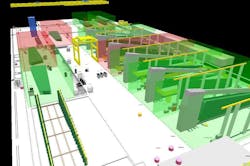

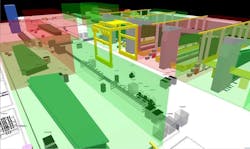

This so-called “cyber-physical” approach—which Airbus calls its “Factory of the Future”—helps streamline tens of thousands of steps in the assembly of an airplane, which can have as many as 400,000 bolts and screws alone and uses more than 1,100 different tools.

“Airplanes are very complicated,” Hentz said wryly.

With those tools connected, the process isn’t only quicker; it’s more reliable than if the bolts were being tightened manually.

Airbus has 11 production sites and four assembly lines worldwide, with another under construction in Mobile, Alabama. It’s been a big user of computer-aided design and, with a nine-year backlog of orders, is pushing “lean manufacturing” to reduce inventory without interrupting production.

“If I can get [the airplane] one day earlier to the customer, I would be very happy. I would receive my check one day earlier and the airline would be able to put the airplane into service one day earlier,” Hentz said.

About the Author

Jon Marcus is a writer based in Boston and a contributor to newspapers and magazines including the Washington Post, New York Times, Boston Globe Magazine, and the Times (U.K.) Higher Education magazine.

About PTC

PTC in Needham, Massachusetts, delivers technology solutions that transform the way you create, operate and service products. PTC solutions for Computer Aided Design (CAD), Product Lifecycle Management (PLM), Application Lifecycle Management (ALM), Service Lifecycle Management (SLM), and Internet of Things (IoT) enable process transformation and deliver closed-loop lifecycle management for products and services that are increasingly smart and connected. PTC solutions are designed to help optimize the activities within individual functions of an organization, and align them across the entire enterprise—from engineering to supply chain and manufacturing, to sales and service. Today, PTC works with more than 28,000 businesses around the world to help them create, operate, and service products in rapidly-evolving, globally distributed manufacturing industries, including high tech and electronics, aerospace and defense, industrial equipment, automotive, retail, consumer, and medical devices. http://www.ptc.com/liveworx/airbus-aerospace-iot

Reprinted with permission courtesy of PTC:

PTC Product Lifecycle Report

5 May 2015

http://blogs.ptc.com/2015/05/05/airbus-uses-iot-to-fuel-factory-of-the-future/#sthash.5S7MkXGO.dpuf

All images courtesy Airbus. © Airbus SAS 2016 – All rights reserved.

You might also like:

Subscribe today to receive all the latest aerospace technology and engineering news, delivered directly to your e-mail inbox twice a week (Tuesdays and Thursdays). Sign upfor your free subscription to the Intelligent Inbox e-newsletter at http://www.intelligent-aerospace.com/subscribe.html.

Connect with Intelligent Aerospace on social media: Twitter (@IntelligentAero), LinkedIn,Google+, and Instagram.

Intelligent Aerospace

Global Aerospace Technology NetworkIntelligent Aerospace, the global aerospace technology network, reports on the latest tools, technologies, and trends of vital importance to aerospace professionals involved in air traffic control, airport operations, satellites and space, and commercial and military avionics on fixed-wing, rotor-wing, and unmanned aircraft throughout the world.