Protecting COTS space electronics at the component and module levels, a discussion

By Dan Friedlander

Retired following 44 years in components engineering

Remarks on Daniel Glesson's article "Lowering the cost of spacecraft avionics with radiation-tolerant COTS electronics" published 19 May 2017.

Being an experienced promoter of selected Electrical, Electronic, and Electromechanical (EEE) commercial off-the-shelf (COTS) components use in space (see my three articles published in Intelligence Aerospace), I welcome this important article: “Lowering the cost of spacecraft avionics with radiation-tolerant COTS electronics” by Daniel Gleeson, space business development manager for Acra, part of Curtiss-Wright Defense Solutions. It is perfectly understood that one cannot include in an article all the details of an approach.

I would like to take the liberty to present my feedback based on available information.

The "Smart Backplane", as per my understanding, is an approach consisting of a standardized modular chassis, a radiation-hardened protector of other standard plug-in "affordable commercial off-the-shelf (COTS) electronics modules in a space radiation environment".

It is understood that the approach is an evolution of a non-space standard version.

The statement "The plug-in COTS modules used in the system are manufactured with commercial components" implies that the explicitly mentioned "standard plug-in COTS modules" are identical to the non-space version. This point is the main drive for cost reduction. If this is the case, I assume that at the original design timing, space usage was not a considered parameter in the EEE Components selection process and in the design phase. Consequently, the new approach for the standard plug-in modules' radiation protection is use of a smart module for preventing Single Event Effects (SEE) and shielding to deal with the Total Dose.

Dealing with Total Dose is relatively easy for a very short mission like the mentioned launchers, re-entry vehicles, space habitats. Satellites are more demanding regarding Total Dose levels.

The smart electronics built with radiation-hardened EEE components is supposed to deal with SEE, the main threat, especially the exposure to destructive Single Event Latch-up (SEL). The technique of SEL protection of EEE components by current monitoring, latch-up detection, and quickly switching off the power before the component is destroyed is well known, but it is a last resort method, usually to be avoided. The method implementation involves extra electronics, expensive SEL tests to establish the relevant latch up current, and the relevant safe nondestructive power switch off time. Multiple SELs may impair the relevant component reliability.

The method is optimally applied at component level.

The article does not disclose details of the SEL protection method. However, if the protection is done at module level (most probably monitoring the standard module current), considering advanced low power technologies, the method may not detect all the SELs in the module before damage. In addition, the SEL may be maintained also through I/O pins. Also the other destructive applicable SEEs (SEGR, SEB) shall be dealt with.

The claim of "up to 75 percent cost saving" implies that no extra testing, upscreening, DPA, radiation tests are performed on the plug-in standard module EEE components, keeping the non-recurring engineering (NRE) low. The nondestructive SEUs correction for a standard non-space module (originally not intended to deal with SEU) can be done externally to a certain mission tolerable degree. The SEU may occur not only in random access memories (RAMs).

The presently targeted space applications (in the article) radiation requirements are relatively at the more relaxed end of the spectrum. The mission length has impact on predicted radiation level and SEE occurrences probability. The relevant short duration mission are applicable for launch vehicles, earth to ISS re-entry vehicles. Nevertheless, risk management is the name of the game. One shall be aware what is the tolerable risk for losing a launch vehicle together with the relevant satellites to be deployed or losing a manned re-entry capsule etc.

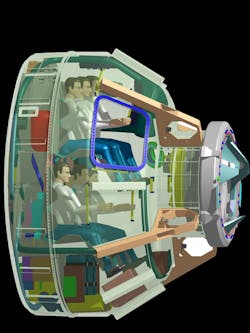

At this stage of not knowing enough detail, the subject “Radiation Tolerant Space COTS” approach selection by Boeing for the Crew Space Transportation (CST)-100 spacecraft is a surprising achievement. In this case, the risk management is not an easy task, considering a space vehicle not flown, manned, reusable. In addition, it is stated that the equipment gathers data from critical vehicle sensors used by onboard computers to make decisions during the flight of the CST-100. All the above are factors and more are factors in the risk assessment.

Author biography

The author, Dan Friedlander, has graduated ENGINEERING SCHOOL/TEL AVIV UNIVERSITY, physics 1965-1969. He has 44 years of experience in Component Engineering at MBT/ISRAELI AEROSPACE INDUSTRIES, 1969-2013, as Head of Components Engineering. He was responsible for all aspects of EEE Components (policy making, standardization at corporate level, approval, etc.) for military and space applications. Retired/Consultancy: 2013 - present.

Further details of experience: see https://www.linkedin.com/in/dan-friedlander-63620092?trk=nav_responsive_tab_profile