High-energy CT inspection provides non-destructive testing, 3D internal inspection for validating critical aerospace parts

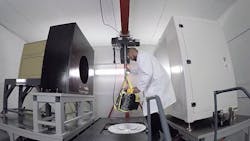

DEARBORN, Mich. Jesse Garant Metrology Center, with offices in the U.S. and Canada, is launching its new high-energy industrial computerized tomography (CT) scanning service, intended to transform the landscape for non-destructive testing (NDT), support innovation within advanced manufacturing, and enable internal inspection in 3D and 100 percent validation of production parts for aerospace, including space and aviation, applications.

The system is the first of its kind that pairs a 3 MeV cone-beam x-ray source with a large-format 2k x 2k flat-panel digital detector. It will be able to accommodate rapid inspection of mid-size parts, up to 44.5 inches in diameter by 63 inches in height. The new capabilities will directly support the aerospace and aviation industries, allowing for a feasible internal inspection in 3D and 100 percent validation of production parts.

The technology will be a key factor in the inspection of flight critical parts, especially as aerospace shifts toward greater use of additive manufacturing. It will also be advantageous for maintenance, repair, and overhaul (MRO) activities, as selected assemblies and subassemblies can now be inspected without costly disassembly for diagnostic purposes.

“It’s always been embedded in the vision of the company to provide trusted solutions that create meaningful advancements in industry. The new computed tomography system is a huge leap forward for mid-size part validation and feasible high-volume part inspection,” says Jesse Garant, president, Jesse Garant Metrology Center.

The unique system offers multiple advantages for non-destructive testing, including a drastic reduction in inspection time for scanning mid-size parts and assemblies. While existing high energy CT inspection services may take 4 hours to 16 hours to complete scans, the new system is able to scan parts in less than an hour. The service will also be beneficial for inspection of multi-material parts and assemblies, allowing for cleaner separation of internal components, and inspection of higher density materials not possible with lower energy micro CT systems.

“We’re helping manufacturers qualify and validate parts that either weren’t possible because of limitations with existing technologies or weren’t feasible because the service was too costly or took too much time,” Garant adds.

The company aims to fill the gap in current inspection technologies that limits the application of industrial CT technology due to part size and density. This will allow for internal inspection and dimensional validation of high-value parts that would otherwise go into production without proper inspection.

The exclusive technology will also provide useful analyses for aerospace, including porosity identification, composite inspection, wall thickness variations, reverse engineering of relic parts, and metrology data for fulfilling AS9102 first article inspection reporting requirements.

The costly endeavor lead by the company required a sizeable $4.5 million investment in technology as well as three years of planning, design, development, and construction to reach full operation. The new system required sourcing from both local and international manufacturers, vendors, and specialists, including the construction of the largest 1m x 1m flat-panel detector in the world.

With federal operational permits currently in place, the new system is now live. Jesse Garant Metrology Center is currently taking on orders from companies who wish to access this innovative technology during the system’s ramp up period.

Founded in 2009, the company was one of the early pioneers of using CT technology for industrial inspection in North America. Since its inception, the NDT and metrology lab has conducted tens of thousands of inspections for major companies from around the world. With a total of $15 million invested into imaging technology over the past five years, the company has steadily expanded to meet the growing demand for frequent and large volume inspection projects in the North American market.

Jesse Garant Metrology Center is a globally recognized part inspection company, providing non-destructive testing (NDT) and metrology services using advanced imaging equipment. The company specializes in industrial CT scanning, industrial x-ray, and 3D scanning, with locations in Dearborn, Michigan and Windsor, Ontario.

Search the Aerospace & Defense Buyer's Guide

The go-to resource for Intelligent Aerospace technology news & information:

Covering key topics

Across all market segments

Subscribe to the free Intelligent Inbox e-newsletter

Subscribe to receive all the latest aerospace technology news & information, delivered directly to your e-mail inbox twice a week (Tuesdays and Thursdays). Sign upfor your free subscription to the Intelligent Inbox e-newsletter at http://www.intelligent-aerospace.com/subscribe.html.

Connect on social media

Keep pace with aerospace innovation and opportunities via your favorite social media channels. Connect with Intelligent Aerospace on Twitter (@IntelligentAero), LinkedIn,Google+, and Instagram.