NASA Space Technology Mission Directorate develops heat-shield thermal protection system with 3D Bally Ribbon Mills material

A designer, developer, and manufacturer of specialized engineered woven fabrics, BRM won a Space Technology Award from NASA’s Space Technology Mission Directorate (STMD) for weaving the 3D material used to support the HEET team’s TPS development. The award was announced at the at the STMD quarterly meeting in Washington, D.C.

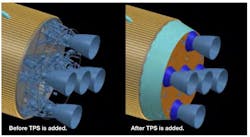

To manufacture TPS materials with the desired properties, fibers of different compositions and variable yarn densities are accurately placed in a 3D structure. Three-dimensional weaving extends the traditional 2D weaving by interconnecting woven material in the third direction, enabling the manufacturing of materials that are more robust to the entry environment than traditional 2D woven materials. The panels are then infused with resins and cured to lock the fibers in place.

Using advanced modeling, design, and manufacturing tools to optimize the weave for overall improved performance, the HEEET project has manufactured a new family of TPS materials and tested them for a wide variety of entry conditions.

BRM and NASA efforts are a great example of NASA partnering with an American small business with a unique specialized technological capability that will further current and future exploration plans, officials say.

“The STMD community sincerely appreciates your hard work, leadership, and dedication to providing NASA and the Nation with revolutionary new technologies and capabilities,” says STMD’s Acting Associate Administrator Stephen G. Jurczyk. “Congratulations on your hard work and dedication to ensuring the success of our Mission Directorate.”

Bally Ribbon Mills (BRM) designs, develops, and manufactures highly specialized engineered woven webbing, tapes, specialty fabrics, woven preforms, and two dimensional and three dimensional structural fabrics. With more than 95 years of textile manufacturing experience, BRM has earned a reputation for meeting new advanced design challenges. Working in aerospace, defense, medical, safety, automotive, commercial, and industrial applications, BRM offers ingenuity, technical know-how, extensive weaving capabilities, and quality assurance systems.