Boeing accelerates, secures additive manufacturing with Assembrix cloud-based software technology

TEL AVIV, Israel. Boeing (NYSE:BA) officials in Chicago, Illinois, are accelerating the company’s use of additive manufacturing, or 3D printing, and better securing the airframe manufacturer’s intellectual property (IP) with the help of cloud-based software technology from Assembrix Ltd. in Tel Aviv, Israel.

Boeing and Assembrix officials have entered a memorandum of agreement (MOA) enabling Boeing engineers to use Assembrix software to manage and protect IP shared with vendors during design and manufacturing.

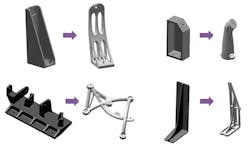

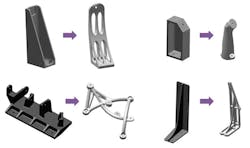

The ability to print parts opens the possibility to create more efficient mechanical designs. (Boeing Illustration)

Boeing is focused on leveraging and accelerating additive manufacturing to transform its production system and support the company's growth. The company has additive manufacturing capabilities at 20 sites worldwide and partners with suppliers across the globe to deliver 3D-printed parts across its commercial, space, and defense platforms. Boeing engineers will use Assembrix's software to transmit additive manufacturing design information using secure distribution methods to protect data from being intercepted, corrupted, or decrypted throughout distribution and manufacturing processes.

"Boeing seeks suppliers globally who meet stringent quality, schedule, cost and intellectual capital standards, and Assembrix does all of that," Boeing Israel President David Ivry says.

"We are pleased to partner with Boeing and value its confidence in us and in our capabilities," says Assembrix CEO Lior Polak. "This collaboration supports our vision to develop and implement innovative solutions that connect the world and take the additive manufacturing digital thread one step forward."

<-- Boeing applied additive manufacturing technology to the CST-100 program to reduce mass, cost and cycle time. The team was awarded a NASA Spaceflight Awareness Award. Some of the members of the team are pictured here with astronaut Ricky Arnold, from left, Erick Li, Nicole Hastings, Matt Herrmann, Sean Dungan, Nick Meyer, Anna Tomzynska, Andrew Scott, Emily Woods and Richard Aston. (Boeing photo)

Today, Israeli industry supplies parts for many Boeing defense and commercial products, including the F-15, the AH-64D Apache Longbow, the next-generation Arrow 3 interceptor, and the 737, 777, and 787 airplanes.

Assembrix developed a cloud-based platform that virtualizes industrial 3D printing, enabling simpler, secured, and more efficient processes, officials say. It oversees the entire additive manufacturing thread from the initial part model to the verified physical part and beyond. The platform enables allocation and monitoring of industrial 3D printers for multiple in-house users or external clients, leading to an automated and self-controlled process, higher printer utilization, and higher ROI.