A new type of airplane wing that adapts midflight could change air travel

Continue reading original article

The Intelligent Aerospace take:

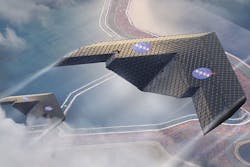

April 1, 2019-MIT and NASA have come up with a new way to make an aircraft wing out of "metamaterials" that utilize triangles of matchstick-like struts to change the shape of the wing during flight automatically - no foolin.'

“We’re able to gain efficiency by matching the shape to the loads at different angles of attack,” says NASA's Nicholas Cramer, who was the lead author of a joint paper between NASA and MIT published late last month in Smart Materials and Structures. “We’re able to produce the exact same behavior you would do actively, but we did it passively.”

According to MIT, the triangle "metamaterials" are put into a lattice that has a density of 5.6 kg per cubic meter and have the same stiffness as rubber, though that material has a density of 1,500 kg per cubic meter. The researchers behind the paper note that the breakthrough could result in the shape of aircraft changing in the future.

"The research shows promise for reducing cost and increasing the performance for large, light weight, stiff structures," says Daniel Campbell, a structures researcher at Aurora Flight Sciences, a Boeing company, who was not involved in this research. "Most promising near-term applications are structural applications for airships and space-based structures, such as antennas."

In addition to aircraft, the researchers noted that the hollow lattice design could prove useful in manufacturing wind turbine blades on site rather than transporting the massive blades over the road, or in construction of large civil engineering projects, like bridges.

Related: Boeing establishing autonomous flying vehicle R&D center at MIT's Kendall Square

Related: Changing how we build satellites could do more than reduce space junk

Jamie Whitney, Associate Editor

Intelligent Aerospace

Ready to make a purchase? Search the Intelligent Aerospace Buyer's Guide for companies, new products, press releases, and videos