Air Canada becomes first airline to install GaN de-icing technology from De-Ice

BOSTON - Montreal-based Air Canada sought a technology-focused way to keep their fleet free from ice and ready for takeoff. They found their solution from De-Ice in Boston.

The company, which uses electromagnetic technology to de-ice aircraft announced that its first customer, Air Canada, will begin the first-ever installation of De-Ice systems on an Airbus A320-series aircraft this winter, with other aircraft planned to follow. Today's chemical-spray ice removal process can add 30 to 45 minutes to the journey. This new technology will meaningfully reduce the departure delays and the carbon footprint associated with chemical de-icing.

Today, commercial and military aircraft use sprays made with propylene or ethylene glycol to remove ice and prevent it from accumulating. This involves manufacturing, transporting, and heating chemicals.

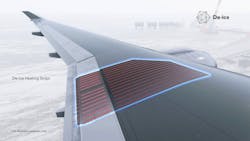

The De-Ice system consists of tape-like strips attached to the airplane's exterior. The strips connect to proprietary electronics inside the aircraft. When activated by the pilot, the De-Ice system generates a high-frequency current, causing electrons on the plane's surface to jiggle, generating heat. This melts snow and ice during the boarding process, leaving the aircraft ice-free and ready for takeoff.

Using a semiconductor called gallium nitride (GaN), the De-Ice system generates high-frequency current using devices that weigh an order of magnitude less than traditional equipment. Before GaN, transistors capable of generating such high-frequency currents were made of silicon, which is too inefficient to be used on aircraft for this application.

De-Ice spun out of Massachusetts Institute of Technology (MIT) in 2015 when Alexander Bratianu-Badea experienced flight delays due to chemical ice removal. He and co-founder Ruben Toubiana set out to develop a fast and sustainable way to de-ice aircraft.

Since then, the company's team of scientists and engineers has developed a novel technology that uses high-frequency electric current to de-ice aircraft without using chemical-based de-icing fluids. The technology also meaningfully reduces carbon dioxide (CO2) emissions. De-Ice has collaborated with regulatory and safety experts throughout the development process to bring the product to market.

"Not only will De-Ice technology be positive for our customers by reducing delays related to the conventional method of aircraft ice removal, but the environmental benefits of chemical-free de-icing and associated lower fuel consumption are in line with Air Canada's commitment to a net zero emissions goal from all global operations by 2050," said Murray Strom, Senior Vice President, Flight Operations and Maintenance at Air Canada. "We have long been an innovative company, having pioneered many winter flying safety measures, and we are proud to be the first airline in the world that will install this technology, which will be the first major advancement in de-icing technology in decades."