Graphics & simulation continue to improve as microprocessors boost their power

By John Rhea

Commercial off-the-shelf single-board multiprocessors are taking center stage in the new breed of computationally intensive simulation and mission-rehearsal systems, while the AltiVec processor is expected to make substantial inroads

Systems engineers who are designing simulation and training devices are making the most of ever-more-powerful and affordable electronics. They are expanding their work across a spectrum that encompasses simple, easy-to-use portable systems to train deployed military forces, as well as traditional high-end, computationally intensive applications in complex systems.

There is an interaction between technology and requirements, notes David Fluegeman, general manager of PC simulation at Evans & Sutherland in Salt Lake City. As military leaders see affordable low-end systems just over the horizon, they feel more confident about initiating development of trainers to tackle their real world problems of integrated force activities. In the past, they were limited to training individual units, but the evolving technologies are beginning to allow them to fuse forces.

There is also an interaction between the commercial and military markets. David Figgins, group vice president for simulation at Evans & Sutherland, sees a commonality between the company`s civil aircraft simulators, which represents about 25 percent of its sales, and the new families of military trainers. With nearly $200 million in sales last year, the company dominates both markets and can transfer technologies to where they are necessary. The company`s sales split of 60/40 overseas and domestic also reflects the simulation business generally, although the recent economic downturn in Asia is expected to drive that split toward 50/50.

An example of the migration of tactical training to ever-smaller systems is the introduction by Evans & Sutherland in July of a PC-based product known as simFUSION in the $15,000 to $20,000 price range. This is essentially an entry-level system, explains Dave Bateman, director of business operations for simulation at Evans & Sutherland: a small Windows NT server in a 19-inch rack using an Intel motherboard and built from commercial off-the-shelf (COTS) components. The system complies with the industry standard graphics language, or GL, and is scalable to embrace applications ranging from arcade game developers to part-task trainers.

This is not yet a ruggedized system capable of field deployment, Figgins adds, but he says he is confident the company can build one if there is sufficient demand. For now, the idea is to introduce new users to affordable simulation. The primary interest has been from civilian aviation, air traffic control, railroads, and automotive users. The company`s previous bottom-of-the-line models cost $35,000 to $45,000.

An existing Evans & Sutherland system, the unit level tactics trainer, or ULTT, exemplifies the current "classroom" mode of tactical training. Company officials have been shipping this system, originally priced at $1 million, for the past two years to the British army for mission rehearsal prior to overseas deployment. The connecting thread is an open-system architecture across the company`s product line. It is not necessarily new technology that makes possible the expansion of the simulation spectrum, as Figgins puts it, but the ability to scale systems to users` needs.

For example, the military services are upgrading their training ranges with electronics that involve satellite and microwave radio data to track objects on the battlefield. Individual soldiers can wear detectors, and a rich picture of the battlefield emerges from advanced displays in the combat vehicles. The net result is a detailed set of battlefield data that is available to users who need the data. This, in turn, gives military leaders a cohesive vision of what they can accomplish.

Wayne Fowler, a systems consultant at Intergraph Corp. in Huntsville, Ala., also makes the distinction between traditional classroom-type training and the trend toward bringing the training systems out to the field. "We`re not down to laptops now," he says, "but we can use luggable lunch boxes for the air crew." Fowler also is involved in his firm`s work on mission planning for the U.S. Army Boeing AH-64 Apache attack helicopter, which requires survivable hardware.

The "lunch boxes" for the Apache crews measure about 14 by 7 by 18 inches, weigh about 40 pounds, and cost around $10,000 with software, he says. For Apache headquarters operations Intergraph produces a standard workstation measuring about 6 by 20 by 19 inches contained in a transit box and linked to an 18-inch flat panel display with a keyboard. This runs around $15,000 plus software.

The purpose is to enable Apache aircrews to train using a digitized terrain database, in which the system also knows the capabilities of all the hostile air defense weapons. This way, crews can select a flight path through this environment, and pilots can view the lethality range and altitude of the air defense weapons in three dimensions as "threat domes," Fowler says.

An underlying factor that enables the military services to implement computer-based simulation and training is the growing familiarity with computers on the part of recruits, Fowler notes: "The kids are more computer-literate and have become used to Windows in high school and college." This is particularly important, given the constant turnover in personnel, and reduces the burden on the services to provide basic computer skills.

The new COTS hardware and readily available software also enable the military to jump on the flourishing trend toward distance learning. Army leaders at the Armor School in Fort Knox, Ky., are looking for what they call a "virtual TOC," or tactical operations center. This would provide young officers such as the lieutenants and captains with the ability to train at home with personal computers over the Internet and never have to go to the field. This should yield substantial savings in travel costs and use of military ranges, Fowler says.

Another possibility for the technology is maintenance, he adds. The technical manuals needed to service the CH-47 Chinook or Apache helicopters weigh about 70 pounds and have to be dragged out to the flight line, where maintenance personnel thumb through them, sometimes under severe weather conditions. Better to give the personnel a laptop with all that information, as long as the laptop is rugged enough for the environment, Fowler says. The data could be contained in a compact disk or on the hard drive of a notebook computer or even on one of the new wearable computers. A good place to start, he says, is on the Army`s future RAH-66 Comanche scout-attack helicopter, which is being developed to be a "paperless" aircraft.

The ability to transfer technologies among military training programs is enabling the suppliers to take advantage of COTS hardware and reusable software, says Stephen Gersuk, vice president of visual simulation programs at MultiGen-Paradigm Inc. in Dallas. The company is providing the run-time software and the image generators, as well as database tools and expertise, for the F-16 mission training centers that Lockheed Martin Tactical Defense Systems in Akron, Ohio, is developing for the U.S. Air Force. Participation in this program enables MultiGen-Paradigm to leverage technology developed earlier for the Joint Strike Fighter (JSF) multi-spectral database.

The company`s work on JSF, begun early in 1997, has gone through a series of enhancements, adding out-the-window views, infrared, and radar to give flight crews 360-degree visibility in the seven-channel model over an area of 320 by 345 nautical miles, Gersuk explains. The F-16 program picks up on this technology to enable pilots to engage in complex combat scenarios, from mission planning through mission debriefing, for fighter and bomber missions.

Each of the 15 F-16 mission training centers will consist of four high-fidelity simulators, either three- or seven-channel visual systems, networked locally within each facility. However, the ultimate goal is to achieve worldwide interoperability over long-haul networks, Gersuk says. This is part of the previously reported Air Force distributed mission training program, which he calls a major initiative within the service. Initial shipments are due for Shaw Air Force Base, S.C., and Mountain Home Air Force Base, Idaho. The new trainers will join existing systems for the Airborne Warning and control System aircraft — the AWACS — and F-15 fighters.

The competitive advantage for MultiGen-Paradigm is the firm`s existing base of software. This base includes the MultiGen-Paradigm Vega package, used for a variety of comparable applications such as simulating the bridges of ships and architectural "walk throughs." Is this COTS software for training? "Absolutely," Gersuk says.

Another training issue receiving increased attention by the military services is keeping reservists and National guard units up to speed with changing hardware and tactics. An example is the two C-130H trainers delivered in November 1998 and August 1999 to the Air Force Reserve Command`s Dobbins Air Reserve Base, Marietta, Ga. The trainers` maker is Raytheon Co. of Lexington, Mass. These trainers, which active-service pilots, co-pilots, navigators, and flight engineers also use, will operate 18 hours a day, six days a week.

This is a traditional classroom application in which the crews practice takeoffs and landings plus mission scenarios such as formation flight, instrument flight, emergency procedures, ground handling, low-level flying, and cargo drops. Raytheon officials estimate that 180 crews will train on each simulator every year. Gary Nesta, director of flight simulation at Raytheon Systems Co., stresses the benefits: "These simulators are helping to offload training previously conducted in the actual aircraft." The trainers are integrated with 6-degrees-of-freedom motion bases that simulate the aircraft`s movement. The out-the-window visual scene projected within the simulator provides 200 degrees of horizontal and 50 degrees of vertical display.

In a U.S. Navy application, engineers at DRS Electronic Systems of Gaithersburg, Md., are developing an emulator to replicate the functions of the AN/UYQ-70 advanced display system, as well as old Naval Tactical Data System consoles. The idea is to use COTS and open-system architecture for the shore-based functions, such as operator training and testing, range and surveillance operations, and software development. There is no need to perform these functions with expensive shipboard-qualified hardware, contends Mark Newman, chairman of the parent company, DRS Technologies in Parsippany, N.J.

A supporting technology for training networks comes from Advanced Simulation Technology Inc. of Herndon, Va., with its line of digital audio communications systems. These systems, based on digital signal processing chips, enable the networks to deliver a variety of sounds and radio communications necessary for realistic training. These can be actual sounds, such as those of aircraft in flight, engine noises, and voice communications, and also digital data for electronic warfare, navigation aids, and even background noise.

The idea is to offload these data from the host processors involved in training and enable users to select aural cues and radio communications. These can be synthesized signals or playbacks of recorded files, and the subsystem is scalable to user requirements: rack-mounted VME configurations embedded into training systems or PC-based systems and workstations for wide area networks. This also is an example of COTS, in which military applications for aircrew training, combat vehicles, and shipboard communications systems share technologies with civil aviation simulators, nuclear power station trainers, and NASA space missions.

A far-out application — literally — of evolving simulation technology is in NASA`s International Space Station (ISS). Here, NASA engineers are using software from Muse Technologies Inc. in Albuquerque, N.M., to lay out the spacecraft and plan for crew operation. The software, also named Muse, for multi-dimensional use-oriented synthetic environment, created a three-dimensional model of the space station placing the equipment and human operators along with the scientific payload and a simulation of the solar system. The software also simulates the crew return vehicle and the reentry of the vehicle into the earth`s atmosphere.

Since the space station has evolved over several decades, it has accumulated data in many dissimilar formats, including real-time simulations produced from old Fortran code and commercial computer-aided design programs. These must be coordinated into a common database available to all the developers. Moreover, NASA`s goal is to make the database accessible from remote locations. Engineers at the Langley Research Center in Hampton, Va., collaborate on payload simulations with engineers at the Stennis Space Center in Hancock County, Miss. This involves data fusion to conduct multi-level simulation. This also dictates an open system architecture so that all the developers are on the same page.

From individual soldiers on the field to the 460-ton space station, affordable COTS technologies are changing the way training is done — and reducing costs in the process.

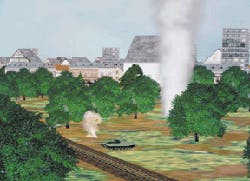

This simulation, from the simFUSION system from Evans & Sutherland, depicts tank operations in Europe. It demonstrates the quality of images that this relatively low-cost system offers.

This simulation image from Silicon Graphics Inc. depicts a stirred tank with a radial-flow impeller. The ability to show this dynamic image graphically shows the power of today`s relatively inexpensive simulation systems.

AltiVec technology to be employed in sonar, radar training tasks

CHELMSFORD, Mass. — The release of the new Motorola MPC7400 PowerPC microprocessor embodying AltiVec technology by the Motorola Semiconductor Products Sector in Austin, Texas, will have a major influence on the simulation training industry. This is the prediction from Steve Paavola, marketing manager at Sky Computers Inc. of Chelmsford, Mass., who already has a customer and expects to begin shipping boards in quantity this month.

The initial customer is Lockheed Martin Tactical Defense Systems in Goodyear, Ariz., which will use the powerful board in a synthetic aperture radar on the Global Hawk unmanned aerial vehicle after initial qualification tests on a C-12 test aircraft. Paavola says he also sees training applications for radar and sonar operators. The powerful single-board processors would generate the dynamic signals for the operators to train against. He calls the process "significantly compute intensive" and says it requires several processors.

Other recently announced entrants into the AltiVec sweepstakes include Synergy Microsystems Inc. in San Diego; Transtech DSP Corp. in Ithaca, N.Y.; and CSPI Inc. in Billerica, Mass. All are also expected to begin shipments this month.

The Sky boards, called Merlin, contain four 333 MHz AltiVec microprocessors to deliver 10.6 billion floating point operations per second (gigaflops) on one 6U VME board multiprocessor. As many as four Merlin cards on a 9U VME board provide 42 gigaflops. Sky officials announced a delivery schedule of 90 days after receipt of order at prices beginning at $25,000 in single-unit quantities.

Paavola estimates simulation applications will account for around 10 percent of the sales for these boards. The strong computing power will be particularly useful in sonar simulations, which must separate various background noises, such as fish, from ship sounds. In addition, operators must be able to identify ship categories by their sound signatures. He cites other potential applications in radar test sets, stress analysis, bomb simulation, and weather simulation.

Synergy Microsystems is also taking orders for its line headed by the VSS4 quad-CPU board specified to deliver 16 gigaflops on VME and Compact PCI boards, says Ron Marcus, director of marketing at Synergy. The company is also offering single- and dual-processor boards. The new AltiVec technology broadens the market, he says.

CSPI`s version of AltiVec is the new 2840 multicomputer, part of the CSPI 2000 series product line. This is packaged in a 6U VME board and combined with the company`s Myrinet high-speed networking capability. The 2840 is compatible with the other boards in the 2000 series and existing software. Transtech`s TPE3 version is available on PCI for inter-processor communications.

The Merlin single-board multiprocessor from Sky Computers, pictured at left, has four AltiVec microprocessors and offers power of 10.6 billion floating point operations per second. Engineers can use these boards for computer-based simulation and training, as well as for radar and sonar applications.