Managing obsolescence takes commitment to ‘best practices’

By Timothy J. Connors

Recent military conferences and government agencies have redefined obsolescence as diminishing manufacturing sources and material shortages (DMSMS). Managing obsolescence is becoming a total business commitment that requires processes that cross over many organization boundaries.

Proper management is critical at a time when industry faces increased demand on sustaining an existing design for a relatively long life cycle.

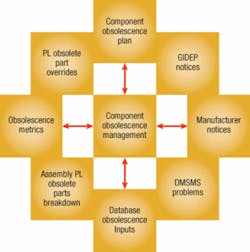

The role of the parts obsolescence management team is to promote a process by which team leaders can predict parts, materials, and equipment shortages-and mitigate problems-to keep cost overruns and schedule slips to a minimum. Figure 1 shows the types of practices that feed a well-managed area in a military business dedicated to mitigating obsolescence issues.

A component obsolescence plan should follow the requirements of EIA Standard 4899, section 5.5.3 describing the plan in three main subjects. The plan shall document the processes used for obsolescence awareness; used by the plan owner to resolve obsolete component occurrences to assure continued production and support as required; and used by the plan owner to minimize the future effects of component obsolescence.

The Government Industry Data Exchange Program (GIDEP) maintains a Web-based technical database with data on engineering, failure experience, metrology, product information, and reliability-maintainability.

One shared information database contains GIDEP notices listing parts and materials that have been, or are about to be, discontinued by the manufacturer. Tracking the notices and checking against parts lists ensures these parts and materials are loaded into an obsolescence database.

Manufacturing notices are the same notices sent to GIDEP. The problem of relaying on the manufacturer to send notices directly to the industry using the parts is not having a key recipient who can make sure the data gets sent to the right person.

When the GIDEP and manufacturing notice processes fail and the part is on order, a problem statement usually goes back to the originator of the order indicating a no bid. When this occurs, it is usually too late to change the parts list for another part; the problem has to be solved through a product line team, which takes time and money. This type of reaction should be the exception and not the rule when it comes to obsolete parts.

When attempting to manage obsolescence without a controlled database, designers face unacceptably high risks of using an obsolete part or one that has reached its maturity. The best place to start tracking parts is at the component level. Most companies have experts who own different commodities such as microcircuits, connectors, passive devices, and hardware. Having a database to load obsolete parts data and code explanation concerning obsolescence issues is as important as loading a parts list and its parts.

A periodic review of production parts lists for obsolescence issues is a good practice to follow. The data can be a metric on the health of the assemblies before the next procurement stage or lot build. Once the designer queries the obsolete database and the parts list database for obsolescence codes against the parts list, he can generate a report for program review.

Obsolescence metrics is a way to track history and trends. The intent is to use the data to mitigate obsolescence issues and know what processes are working or need fixing.

A check system must be set up to identify parts and materials with obsolescence codes to prevent the use of obsolete parts in new designs. There are many ways to accomplish such a system, but one that has worked very well for Lockheed Martin Maritime Systems & Sensors in Syracuse, N.Y., is an attribute labeled “OBS Code” linked to the part master.

Any time designers use the part master in a new project, a program checks for any codes; if it finds a code, it places a hold on release until the obsolescence issue is resolved or given an override for that particular project parts list.

It may look simple to say the part is obsolete or not obsolete. Therefore, someone would say, “I only need one code.” The consequence of this narrow view is the failure to identify other parts having obsolescence issues in a database, and therefore, not showing them as a problem or issue in new designs.

The best overall approach is to have attribute codes covering all levels of obsolescence in addition to those that are known to be obsolete.

Designating an obsolescence system of codes that accomplishes the main objective of mitigating obsolescence should include a Code 1 (worst case - part obsolete with no known form, fit, and function replacement) with higher numbers indicating a range of critical problems and less severe issues.

The word “critical” in this situation means the design activity needs immediate attention to resolve part and material problems before it becomes too costly. The words “less severe” mean parts and materials are still procurable, but NOT for new design because of technology, documentation exceptions, or manufacturing cost issues.

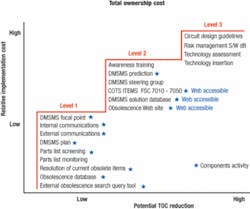

A presentation from the 2002 Military DMSMS Conference defined three levels of implementing specific obsolescence tasks by level of cost to achieve the highest degree of total ownership cost reduction. The chart, Figure 2, was modified to show the component activity with respect to each level.

Level 1 and 2 can easily by accomplished with the use of component engineers knowledgeable in parts control. Achieving Level 3 requires a higher organization other than components engineering dedicated to the practice of meeting customer expectation through design refresh and life cycle risk management. A Level 3 implementation is more costly and therefore may not be suited for every company.

Factors to consider when striving for Level 3 compliancy include size of business; life cycle greater than five years; and contract requirements for component and assembly risk management.

Sustaining aging aircraft by DMSMS management

As parts used on an aircraft in production for more than 10 years become obsolete, a system of identifying these parts and managing these parts to continue future production must be in place.

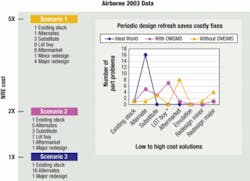

Even in an ideal world of managing obsolescence, customers usually pay for redesigning assembly boards that contain obsolete parts with no direct replacements. It is important that the number of these changes should be minimized using DMSMS plan. The chart in Figure 3 shows a rule stick on nonrecurring engineering (NRE) costs that would occur under different scenarios.

In the first scenario, without DMSMS, many of the alternates, substitution parts, and lot buys would be missed in the life cycle, and would translate into higher NRE cost for aftermarket and redesign solution. The cost involves the same problem part data recorded in 2003 for the airborne product having DMSMS component practices.

One can argue that the part quantity would actually increase since more problems would occur if the resources and controls were not in place to monitor sources of supply. The key idea is to show a direct relationship of no DMSMS practice to higher cost solutions.

In the second scenario, with DMSMS, actual problem sheets with obsolescence part numbers shows a much higher part solution at a lower NRE cost using alternate, substitution, and lot buys. The necessary component resources, external database search capability, GIDEP notices, and manufacturer’s notices are all in place before a critical problem occurs.

In some cases lot buys sustained existing configuration. Lot buys or bridge buys give the project time to phase in a redesign at a later date.

In the third scenario, an ideal world, design concept, implementation, and production stages are in place with parts-list baselines for all assembly boards; risk management has decision-making authority, teaming and steering groups are active in making resolution on critical obsolescence problems, and funding is in place to act on design-technology insertion.

In theory, with Level 3, the technology refresh would anticipate the time required to cut-in a new system architecture that would meet the functional requirements of the original design.

Timothy J. Connors is lead engineer of parts obsolescence management at the Lockheed Martin Maritime Systems & Sensors division in Syracuse, N.Y., where he manages an obsolescence database containing more than 19,000 parts and reports obsolescence status on Radar Systems parts lists.