Space: the next frontier of rad-hard

Burgeoning commercial satellite market confronts designers with cost and time-to-market pressures and opens new options in shielding, upscreening, and system redundancy.

The past few decades have seen vast changes in the market for radiation-hardened electronic components. Since the 1990s, the rad-hard industry has evolved from Cold War-driven demand to enable military electronics to survive and even operate through nuclear weapons explosions, to today's needs for radiation-hardened parts that can operate for lengthy periods in space.

The market's transition to space applications is not the end of this market evolution - far from it, in fact. Today's vibrant space market involves a transition from monolithic satellites the sizes of school buses to so-called "disaggregated" satellites that involve orbiting clusters of spacecraft tied together by wireless data links.

This emerging market transformation to spacecraft disaggregation is giving rise to electronics design trends more akin to the commercial market than to what we've become accustomed to in space. Satellite systems designers today are under more cost and time-to-market pressures than ever before, which is forcing designers to sharpen their pencils and come up with new ways of delivering space products quickly, at reasonable costs, and that can survive the harsh radiation operating environment of space.

The nuclear threat

Before the Berlin Wall came down in 1989, the rad-hard market was in place primarily to design and manufacture electronic components that could operate through the intense radiation of a nuclear weapon explosion. Cost was no object in America's global struggle with its adversary the Soviet Union.

An established rad-hard supplier base that included companies like IBM, TRW, and Honeywell took great pains and incurred great expense to craft microelectronics design methodologies to yield analog and digital parts that either could operate through a nuclear event, or had the circuitry onboard to detect a surge in radiation and shut down vulnerable parts before damage occurred.

Space applications still were an important part of the rad-hard market back then, but did not wield nearly the influence that they do today. Military communications and reconnaissance satellites like MILSTAR and the KH-11 "Keyhole" satellites were important drivers of rad-hard designs, but these spacecraft were designed to survive a nuclear blast in space.

Military rad-hard parts during the Cold War were not restricted to space applications; there were plenty of ground-based systems like strategic communications and combat vehicles that benefitted from the rad-hard electronics supplier base.

Yet the end of the Cold War slackened demand for rad-hard parts, and today what then was the traditional rad-hard supplier base has dwindled to a handful of suppliers. This is not to say that nuclear weapons applications have no influence on the rad-hard market. U.S. land- and sea-based ballistic missiles, for example, still have stringent radiation-hardening requirements.

Still, technological needs today revolve around the burgeoning commercial satellite market, rather than the need to survive nuclear explosions. This market shift has imposed a fundamental transformation on the rad-hard electronics market.

The challenges of space

Substantial amounts of radiation in the form of charged particles occur naturally in space. Much of this naturally occurring space radiation comes from the Sun. Much of this space radiation is much less intense than the radiation produced by nuclear explosions, yet still is a primary factor when it comes to operating in space.

Earth's orbits moving out from the planet's surface typically have different levels of radiation. There are two primary belts of radiation formed as layers of energetic charged particles that the Earth's magnetic fields hold in place. These two radiation belts, one inner belt and another outer belt, are called the Van Allen belts.

The so-called South Atlantic Anomaly is part of the inner Van Allen Belt, where the radiation field is closest to the Earth's surface dipping down to about 124 miles in altitude. Between the inner and outer Van Allen Belts is a relatively benign area typically called the safe zone, where radiation is not as intense as it is within the Van Allen Belts.

The upper reaches of Low-Earth Orbit are within the lower Van Allen Belt, and can pose significant radiation risks to the electronics of orbiting satellites. Spacecraft orbiting in the higher-altitude geosynchronous orbit can be exposed to the outer Van Allen Belt.

The point is that different orbits have different levels of radiation. Spacecraft designers must account for the radiation found in their intended orbits.

Charged particles in radiation environments can cause malfunctions, damage, or even destruction of electronic devices, depending on the intensity of the radiation and duration of radiation exposure. Space electronics subject to radiation over time, moreover, can experience degradation in performance, shortened life cycles, or even major failures.

Solid-state memory chips, for example, can experience bit flips when hit with charged particles, which can corrupt stored data. Another kind of single-event upset is called a single-event latchup, which disrupts how the part functions. Curing the problem usually requires shutting down and powering up the affected part. Without this kind of correction the part can go into overcurrent, which can cause damage or destruction.

Evolving space applications

There was a time years ago when virtually all satellites required use of electronic components that were designed from the ground-up to be rad-hard. A widening variety of satellites and spacecraft applications, however, has broadened design options.

Radiation-hardening levels represent calculations of expected intensity of radiation, and duration of the satellite's lifetime.

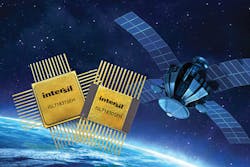

"Space has been a relatively boring industry for a while, but over the past two or three years things have gotten very exciting," says Joshua Broline, product marketing manager for military products at rad-hard specialist Intersil in Palm Bay, Fla. Growing interest in small satellites, CubeSats, and disaggregated satellites is opening a variety of radiation-hardening options, he says.

Depending on mission orbit and duration, designers can choose from options that range from rad-hard by design, commercial off-the-shelf electronic components that have been upscreened for reliability, to various rad-hard approaches that use a combination of radiation shielding and error correction.

Companies that specialize in radiation-hardened components typically have the design expertise to blend a variety of techniques, recommend parts appropriate for the job, and provide shielding, redundancy, and error correction where necessary.

"The trick is to pick the right technology and ask if it meets your needs and will be sufficient for the project," says Intersil's Broline. "There are a lot more choices today in rad-hard than there were 20-plus years ago."

Some satellite applications don't require any radiation-hardened electronics at all. Those typically include experimental satellites of extremely short lifetimes of a few months to just a couple of weeks.

"For those putting up satellites for missions of three to six months sometimes there are no requirements," says Anton Quiroz, business area director for systems and development at Cobham Semiconductor Solutions (formerly Aeroflex) in Colorado Springs, Colo.

"They just put it out there and hope it functions," Quiroz says. These can include university research projects, short-term Earth- observation satellites, or temporary military communications satellites designed to provide short-term connectivity to battle theaters.

Other short-term satellite applications can require only light levels of radiation hardening, which can help operators avoid high costs. These include the so-called SmallSats and CubeSats, which are being designed to operate in low Earth orbit (LEO) for about one to five years. These applications require a minimal level of radiation hardening, Quiroz says.

New Space

Some call these applications New Space, or Low-Cost Space, says Larry Longden, vice president and general manager of the Data Device Corp. (DDC) Microelectronics Group in San Diego (formerly the Maxwell Technologies Microelectronics Group). Among these are the proposed OneWeb and SpaceX small satellite constellations to blanket the globe with Internet access.

OneWeb seeks to launch more than 600 tiny satellites orbiting at 750-mile altitudes to beam high-speed Internet down to Earth.

SpaceX, meanwhile, seeks to launch 4,000 SmallSats in 750-mile-high altitudes for the same purpose. Internet search giant Google reportedly has provided $1 billion to help fund the SpaceX project.

These kinds of satellites would have short life cycles presumably because they could be replaced quickly and inexpensively. Their required levels of radiation hardness is open to debate.

There have been some hard lessons learned in recent years when it comes to on-orbit failures, which could make designers think twice about cutting corners with radiation hardness - even with short-duration satellites.

"A company trying to make money out of what the payload is doing might want to make it more reliable," warns Cobham's Quiroz. For these applications radiation levels of about 25 kilorads might be sufficient, he says.

Satellite designers for New Space applications often will try to avoid radiation-hardening components throughout the spacecraft, but concentrate hardening efforts only on those components performing mission-critical functions, like attitude and telemetry, data handling, and databus functions, Quiroz says.

Low-Earth Orbit

Satellites designed to operate in low Earth orbit for durations longer than five years might need more stringently radiation-hardened components - especially since these spacecraft will be exposed to the inner Van Allen belt.

"If you're operating in LEO for five to seven years, then you need significant radiation hardening above commercial level, and you need to move above commercial plastic-packaged components to something more robust, like ceramic," says DDC's Longden. "You're typically talking about 20 to 50 kilorads total-dose, and a high-flux environment."

For these kinds of environments satellite designers typically call out well-known rad-hard standards like MIL-PRF-38535 and MIL-PRF-38534, when these kinds of parts are available. These are the gold standards when it comes to radiation hardening, and designers choose these parts over upscreening and shielding wherever they can.

"The costs can be the same of a rad-hard-designed part or a COTS [commercial off-the-shelf] part that needs to be upscreened," says Intersil's Broline. "Assuming that the costs are similar, you don't have to convince a designer to use the rad-hard part. It represents a standard flow, is well recognized, and is a lot easier to get passed."

Sometimes components are unavailable that meet these kinds of standards, however, which poses a bigger challenge for space systems designers.

"If there is no other path, the upscreening takes more time, effort, and money to convince the end customer that it is flyable, and that the parts supplier has done his due diligence," Broline says.

Higher orbits

Moving to higher orbits from LEO can present different challenges for satellite designers. Although there may be less radiation at higher orbits, the charged particles higher up can affect electronics differently. "Protons and electronics hit the satellites harder" in higher orbits such as geosynchronous orbit, says Cobham's Quiroz.

"Through GEO is where we see the 100-kilorad total-dose requirements," Quiroz says. Satellites operating in GEO typically also have longer life cycles (as long as 15 years), so hefty rad-hard requirements are the rule for these designs. Roughly the same requirements are necessary for polar-orbiting satellites.

For more stringent requirements, designers often look for electronic component technologies that are inherently rad-hard, such as those fabricated on silicon-on-insulator (SOI) processes. "Those processes are very difficult to upset," Quiroz says.

Beyond GEO venture the deep- space probes that must be able to withstand high radiation levels of open space. Some of these deep-space applications, depending on the anticipated duration, required total-dose radiation hardness of 300 kilorads to 1 megarad. These kinds of parts are difficult to find, and are expensive when they're available.

"Requirements for 300 kilorads total-dose would include the deep-space probes, which must take a lot more radiation, and must look at some shielding on top of that," says Cobham's Quiroz. "We look at the process to ensure that the part will be suitable and make sure what you are working with," he says. "We have a design team that knows its components really well."

For these kinds of applications Cobham offers quantified COTS parts, which "is a commercial product that has been quantified so you know exactly what you're getting," Quiroz says. "We can screen and test parts, and take care of a lot of the up-front headache for the customer rather than have them do the upscreening themselves. We test a lot of off-the-shelf products, and a lot of rad-hard product, as well."

DDC Microelectronics experts, meanwhile, put their expertise to work in the company's RAD-PAK technology, which involves carefully selected parts and shielding. "Think about going to the beach and getting a sunburn," says DDC's Longden. "The longer you spend at the beach the deeper your sunburn. Our RAD-PAK technology is like putting on sunscreen. We take a commercial semiconductor and put it inside of our shielded package to reduce the radiation environment."