Military and commercial avionics draw from the same technology well

The economic imperatives to use as many commercially developed components as possible and to avoid duplication in research and development often put commercial and military aviation electronics on the same track and headed in the same direction.

By J.R. Wilson

Historically, military and commercial avionics have followed somewhat independent paths because of significantly different mission requirements and acquisition procedures. As the speed of technology development has increased dramatically-and the U.S. Department of Defense (DOD) ability to fund its own research and development (R&D) efforts has declined-military reliance on civil development has risen. At the same time, some technologies developed specifically for military use are finding new applications in commercial jetliners.

As a result, the level of crossover technology has grown substantially in both directions. More important, however, is the increasing imperative for the military to be able to adopt and adapt new technologies far more quickly, efficiently, and cost-effectively than ever before. That has led to a dramatic push for new, avionics-specific industry standards for power, form factors, and interfaces that will apply to military as well as commercial aviation.

U.S. Air Force Col. Mark Stephen, associate deputy assistant secretary of the Air Force for science, technology and engineering, says a historically close working relationship among the services and between government and industry has become central to everything the military is doing in the avionics arena. A major driver in that evolution is the need to correct past mistakes.

“We made a lot of technological advances in avionics in the 1970s and ’80s, then put very closed architectures into our aircraft, with line-replaceable units that only worked for a certain block of a certain design, and not much cooperation between services and certainly not within industry,” Stephen says. “We have very much hangered that thought process as we look to the future.”

Dan Slick, deputy chief information officer for engineering and enterprise architecture at the U.S. Naval Air Systems Command (NAVAIR) at Patuxent River Naval Air Station, Md., says the Navy began looking for new ways to do business in avionics about four years ago. Investigating the specific forces behind the costs of operating the Navy aviation fleet, at the direction of the NAVAIR commander, they discovered the primary problem involved aviation depot-level repair (DLR) costs.

Proprietary dilemma

“We proposed various projects to cut costs and almost immediately began to realize, when we went back to analyze those projects, that they weren’t helping much,” Slick says. “We assumed open systems were using open standards, but the various companies each had their own sets, often unique to each other, and so not interoperable despite using open computing standards.”

Nor was there any relief found in taking a more aggressive approach to using commercial off-the-shelf (COTS) technology, which for decades has been subject to Moore’s Law (the number of transistors on a chip-and thus the speed of that chip-doubles every 18 to 24 months).

More and more circuitry is compressed onto a single die, so every two cycles manufactures lower the voltage to keep temperatures down. This creates roughly a 3.5-year technology window for each generation of integrated chips.

“By the time we conceive a component for our aircraft and it is into the program, we are dealing with a seven-year diminishing acquisitions sources time,” Slick says. “We can’t respond fast enough to get COTS components to the fleet before they become obsolete; our acquisition cycle and the computing technology cycle just don’t match up. That’s a huge problem.”

To deal with the issue, the Navy took an ongoing open-systems effort and expanded it into the Modular Open Systems Approach Interoperability Initiative (MOSA II), which is the avionics component of the Navy’s overall Open Architecture program.

“We wanted to get the Boeings, Lockheeds, Northrops, and the rest of industry on the same page, to become truly interoperable,” Slick says. “We thought if we could get programs to select the same standards, that would do it.”

Economy of scale

NAVAIR officials wanted the prime avionics manufacturers to select a set of standards that are not open to the computing industry, but open to the aviation industry. “Only a subset of the computing industry standards are really useful to avionics,” Slick points out. “We also wanted to cover all aviation-not just military, but also commercial-so we could get economy of scale savings.”

In December 2002, Navy officials started meeting with their tier-I and tier-II vendors-Boeing, Lockheed Martin, and Northrop Grumman at the prime level and their major avionics suppliers, such as BAE, Honeywell, and Rockwell Collins.

“We want to have enough commonality across aircraft that we can do plug-and-play between the different vendors, so if I bought a box from BAE, down the road we could buy a box from Smiths Aerospace as a preferred spare,” Slick says. “That means industry must collaborate on standards from an electrical as well as physical standard, and that the data input/output (I/O) is understood and broken up by function. Those three components-electrical, physical, and interface-then would allow us to move around to various vendors.”

That was when 21st-century military needs for rapidly available, low-cost technology insertion ran into a 20th-century business model based on sustainment and proprietary technology.

“They thought we were going to try to standardize intellectual property, but that is the furthest thing from the truth, because we want to continue to instill competition and move forward intellectually,” Slick says. “MOSA does change the current business model, in which their profit-and-cost centers all assume they want to build us an aircraft or put in a box that will allow them to have sustainment throughout the life of the aircraft; they have gone as much as possible to proprietary solutions. MOSA breaks that down so they do not have any proprietary interfaces in our aircraft.”

Outside the box

Yet that is as far as it goes, Slick says. “We’re not interesting in taking that down into the box; how they perform a function is up to them,” he says. “We are just interested in the external parts of the box.”

The Navy found a willing partner in the Air Force, which was pursuing a similar course, and won support from the Joint Aeronautical Commanders Group. After that, the Navy approached the Aerospace Vehicle Systems Institute (AVSI based at Texas A&M University at College Station, Texas) to help make their case with industry. AVSI is an aviation industry cooperative, initiated by Boeing in the late 1990s, to provide industry-wide input on major aerospace systems issues.

“We had several projects that aligned with MOSA, which became very clear to Dan Slick and became a touchstone where we could focus a number of smaller initiatives on the bigger picture of interoperability-probably a dozen in all,” AVSI director David Lund says.

“What we loosely call the ‘needs model,’ for example, is a fairly detailed spreadsheet looking at the world from the DOD, industry, and warfighter perspectives; from it comes the MOSA business model, which won’t work if any of those three are shorted,” says Lund. “It is such a cultural change; it has to be a win-win for all involved. The economy of scale also is necessary to make this work, so when we say industry, we are referring to the broad stroke-military and commercial.”

A final report on that proposal was completed in June 2005 and was still awaiting action by AVSI members and the government as 2005 drew to a close.

“Industry wants to continue to compete on their technology edges and unique functionality, but it has to be done within a broader context of open architecture to allow interchangeability, interoperability. That obviously is a tall order,” says Lund. “The big OEMs (original equipment manufacturers-the tier-I companies) recognize the world is changing so quickly DOD can no longer pick systems in the old way and many now say producing systems that are obsolete on the date of introduction is no longer acceptable.”

The role of suppliers

“The real crux is not on the OEM side, but in the sub-tier supplier set-the avionics systems suppliers. Is this new paradigm of a MOSA business model one in which they can flourish?” says Lund. “When you get down into the supply chain, that becomes a very dramatically different way to operate. Some see that as a way to expand and show off their expertise, while others are worried about changes to the profit centers in their organizations because it is still not completely clear how MOSA affects them.”

There is no such question at the tier-IV level-those doing DMS (diminishing manufacturing sources). Companies that buy the manufacturing rights to obsolete components are not part of a MOSA-based world. Slick says one goal is to eliminate tier IV entirely and put the money into new systems acquisition, which Lund notes also would mean dramatic changes within the DOD acquisitions, logistics, and maintenance communities.

“My member companies are interested in going forward with a new view of what the world of the future will look like and helping them understand how to position their companies to deal with that future,” Lund says. “Whether trying to protect your current operations or become visionary, organizations-DOD or industry-have to be aware of what is possible with MOSA and how that may affect the world in the future. That may require a defensive position as well as opportunities for those who are agile. The fact is, the DOD procurement world will have to change, as will the contractor world.

“If you look at the commercial aerospace world, with global competition, they are approaching MOSA-like activities in many ways already, so the military approach to MOSA has to learn from the commercial world,” Lund continues. “The danger is not to apply what we always like to apply-the computing industry-which is a huge industry with huge volumes. Parallels between what we are trying to do and the PC world are not 100 percent.”

The rash of acquisitions and mergers that swept away many old names in aviation during the 1990s also gave the tier-I companies a major presence in tier II (box and card suppliers) and tier III (components). Slick says Boeing and Lockheed Martin both have conducted internal studies and, while not revealing precise results, have told the Navy they are convinced the adoption of true avionics standards across all aviation is a practical and profitable solution.

Ahead of the curve

Northrop Grumman officials, meanwhile, says they came to that conclusion about the same time the Navy began developing MOSA II, and already have made it an integral part of their revised business model.

“We had a bit of soul-searching four or five years ago, looking at what would drive the avionics industry-military or commercial standards,” says Gorik Hossepian, vice president of situational awareness systems at Northrop Grumman Navigation Systems Division in Woodland Hills, Calif. “The military position on MOSA is our objective. We can’t deliver that on the next platform, but we can take a major step forward.

“Today the mission computer in the H-1 (U.S. Marine Corps Huey and SuperCobra helicopter upgrade) has almost 70 percent reuse in functionality and physically is identical to the mission computer for the Advanced Hawkeye (the Navy’s next carrier-based tactical battle management, airborne early warning and command and control aircraft). We will offer the same type of solution in our future competitions, where we can make the boxes as common and standard as possible.”

Hossepian notes that Northrop Grumman does not make the majority of those boxes, but buys them from tier-III suppliers, creating an architecture of systems, communications paths, and functionality between the various units, managed through a central computer, then displaying that to the pilots and commanders. To that extent, the issue of true standards extends inside the box as well as addressing the military’s requirements outside the box.

“Our approach fundamentally has been to use COTS components, which follow industry standards,” he says. “Just in developing the H-1 box, a lot of those components have gone obsolete, so we just take the next-generation processor, stick it on the card, and into our box, without modifying anything, and have it up and running in a matter of hours. That gives us a much better handle in this world of obsolescence.”

Interchangeable boxes

“The concept of making boxes truly interchangeable is an attractive option to us and the fundamental concept of using a true open architecture is one Northrop advocates and has been using to develop our technologies,” Hossepian says. “That is the future. It also is a real good opportunity to have crossover between military and commercial avionics.”

A similar view comes from Joey Sevin, business development director for the Mercury Computer Systems Radar Business Segment in Chelmsford, Mass. This, he cautions, is not an easy move for anyone, including the military.

“For F-22 and JSF (Joint Strike Fighter), the military wants level-2 maintenance, which means anybody can reach in and pull out a module. So it has to be user friendly,” he says. “But standardization inside the box also is important for us because we know we will move to another processor or module and would like to be able to plug that new module into the same backplane.

“The Navy wants to be able to replace the backend processor with whatever works this year, with the only consistency being the sensor interface,” Sevin says. “That becomes a very hard requirement, with no option to migrate because, if you do, you have to redesign everything back upstream toward the sensor.”

Sevin also says temperature influences far more than just technology cycles.

“Processor heat also is going up because everyone is going to multicore processors,” he says. The IBM Cell Broadband Engine Architecture processor, for example, has nine processors inside the chip-a Power PC microprocessor in the front and eight signal- or vector-processing engines (SPUs)-which provides the ability to do scalar processing with the Power PC and signal processing with the SPUs, to combine decision making closer to the signal processing.

“That’s where our work on VITA 46 and VITA 48 comes in,” Sevin says. “VITA 48 is the actual mechanical standard, 200 watts per slot, air-cooled and conduction-cooled, with up to 500 watts for the liquid flow-through modules. That is a major trend we are dealing with at the module level, which has a ripple effect on the chassis and the power of the overall system.”

When and where those requirements will develop remains somewhat fluid. For example, Sevin says there has not yet been a significant demand for multiple sensors feeding into one processing pool, yet some very complex systems with just such a requirement are on the horizon, such as the Joint Unmanned Combat Air System (JUCAS).

Demand for processing

“We see two trends: platforms sometimes getting smaller but wanting teraflops of processing, and wide bodies wanting 20 or 30 teraflops and even more processors, Sevin says. “In a lot of systems, you have one box capturing and processing data, then turning it over to another box to make decisions. Now that is moving into the same box, even the same processor, which offers a lot of challenges and opportunities for software developers and doing a tremendous amount of processing in a small footprint. For the cell processor, we’re talking 200 gigaflops each. We’ve gone from 400 MHz to 800 MHz, thinking people would buy fewer boards and perform tasks twice as fast; instead, they added more requirements on the subsystem.

“We’re working hard to deliver all the tools, as standard as possible, to take advantage of those processors in whatever application. Standardization inside the box actually helps us. Just as our customers have to deal with change, so do we; that is part of our business plan. We will continue to drive the density of processing-and as we go to more multicore processing, it will get hotter. To put those into tactical fighters and into racks in wide-body aircraft, we must be very clever about how we cool these things.”

A decided upside to the advancements in processor technology allows for more processors in the same or less space. Redundancy, not only for flight-critical systems, as is now the case in jet fighters, but also for mission-critical needs, says Larry E. Hollingsworth, national department head for avionics, at NAVAIR.

“In the future, we will have redundancy-with JSF being the first to demonstrate it-through distributed processing,” he explains. “So instead of having one processor doing all radar, electronic warfare, or optoelectronics, you will have shared resources. If something fries, we will have mission capability, even if at a reduced level.”

The Air Force’s Stephen says the need for new thinking permeates the military approach to all aircraft electronics. New ideas include using wireless headsets from the commercial jetliner passenger cabin for crews on wide body military aircraft.

Extended 1553C

The Extended 1553C databus is an effort to move one of the oldest and most heavily used military electronics technologies into the 21st century, using a take-off on the telecommunications industry’s DSL broadband service that enables high-speed Internet connections using existing home telephone wiring. That may solve the problem of keeping relatively old aircraft closer to the onboard capabilities of new platforms with fiber optic systems.

“We are looking at a technology that will effectively allow us to increase the overall bandwidth of the avionics architecture in our legacy aircraft at a fraction of the cost,” Hollingsworth says. “We have been using 1553 for the past quarter century, at 1 megabit per second. We believe we can get up to 200 to 300 megabits per second using the same wiring structure. We will stick with 1553 with any aircraft that now has it, but restructure that bus to operate at higher bandwidth.

“At least one implementation of the Extended 1553 enables us to do the traditional tasks we have done on the original, but send live full-motion video in both directions on the same wiring at the same time,” he says. “We are a big believer in fiber, but 1553 will be very relevant to our many legacy aircraft in the fleet.”

Stephen says two current mechanisms help move new and crossover technologies along, and a third would replace a once-intrusive government presence in industry R&D with a new cooperative role.

“The first is the dual-use science and technology program, which only does projects cofunded by industry and the (military) labs, looking for things with applications on both sides and developing the technology accordingly,” he explains.

“The second key to a lot of new ideas is the SBIR (Small Business Innovation Research) effort, which allows lower-tier contractors with an idea they believe has military and commercial application to get two years of government funding. Once the technology is mature enough to apply specifically on a platform, we look for additional government, industry or joint funding. A military platform might not yet be at the right point for insertion, but a commercial aircraft might-or vice versa. Congress likes us to help industry open up their markets that way.

“Finally, in the past couple of months, we have tried to reinstitute some knowledge of industry internal R&D programs that is not burdensome-as defense oversight once was-to get an understanding of what the aircraft developers are putting money into that they think may be of interest to military and commercial and perhaps help steer their R&D or leverage it with what we are doing.”

Replacement for ARINC 429

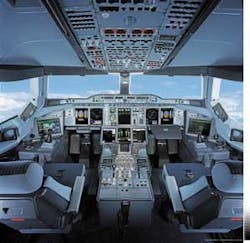

The U.S. military and its contractor community are not the only ones looking to improve avionics through the creation of new standards. For its new A380 super-jumbo passenger jet, Airbus Industrie in Toulouse, France, created a replacement for the ARINC 429 communications bus that Thierry Harquin, senior manager for avionics and electromechanical systems, says the European airframer hopes will become the new industry standard.

“The AFDX (aircraft full duplex switch) is based on the Ethernet bus,” he says. “On some aircraft, you need to make certain the message will take a specific time to go from source to destination. For this determinism, we add a layer of protocols on top of the classic Ethernet bus-seven layers on each bus, the physical layer at the bottom, the application layers at the top. On the top layers, the most intelligent, we have put some actionable protocols to enhance the Ethernet.

“Airbus has been working with the entire community to create this as a standard in the avionics world, so it also can be used by Boeing for the 787. But the A380 will be the first to have this communications bus, which has a much higher bandwidth than the ARINC 429, the current (commercial) avionics standard. With it, we were limited in to 100 kilobits per second, which limited communications, especially in terms of displays. To install an interactive cockpit, we needed higher bandwidth; the AFDX can potentially go to 100 megabits per second.”

While specifically developed for commercial airliners, Harquin says the AFDX may find military applications as a substitute for the 1553.

The A400M, meanwhile, is an example of systems developed for the military-glass cockpits, head-up displays, and electronic vision systems for bad weather-moving into the commercial world. While HUD and EVS will not be available for the start of service for the A380, he says it will be proposed for it and all future Airbus programs, including the A350.

Generic modules

Harquin says a significant avionics advances on the A380 is a modular concept, using generic modules and boards for specific function sets.

“Previously, when you developed an avionics component, you had a supplier provide a specific board, with each supplier doing that for each function needed, such as the flight management system (FMS), with the supplier providing the computer and boards and perhaps software. Then each time you have another function, you need another box developed by another supplier,” he explains.

“With the A380, we asked two hardware suppliers to develop generic hardware modules, such as the processing and input/output modules; these generic boards can host multiple functions, such as displays, warnings, communications and other functions. FMS is a separate system. We also asked for the development of software that can be hosted on these generic line-replaceable units.”

These developments facilitated the Airbus move from cathode-ray tubes to liquid-crystal-display technology, while meeting a strict requirement for lifecycle cost savings and pilot workload benefits for their airline customers, Harquin maintains.

“The ability to develop new avionics on generic platforms and to develop a new high-speed bus are our primary enabling technologies,” he says. “Future development requirements include higher bandwidth, between aircraft and ground, to exchange increasing levels of data. We imagine all sorts of solutions to be able to do that.

“There also is a general trend toward integration. But we still have a high consideration to avoid creating new common points of failure mode, so we have two power supplies for this new cabin,” he adds. “If we lose one power supply, we don’t lose four functions. That also would be a benefit for the airlines in terms of reducing spares. For example, for the A380, we developed a surveillance cabinet that replaced four boxes with one-weather radar, transponder, TCAS and ground proximity warning system.”

Integration trends

At Boeing Phantom Works in St. Louis, the systems/subsystems technology (SST) and information, electronics and avionics (IE&A) teams develop new technologies for avionics systems and components, with application throughout the company’s product lines.

[Military & Aerospace Electronics made numerous unsuccessful attempts over several weeks to solicit input for this article from Boeing Commercial Aircraft.]

For SST, new technologies include autonomous systems, vehicle management systems (VMS), integrated vehicle health management, integrated electronics subsystems and human systems integration.

“With the advent of fly-by-wire flight control, some of the subsystems have become flight critical, which is reflected in their survivability requirements,” SST director Paul Doane says. “Once a collection of federated systems, they are now integrated into the VMS, realizing enhanced capability and supportability via integrated control, diagnostics, and prognostics. Complex relay logic systems and extensive interconnect wiring are being replaced by shared digital processors and communication via digital multiplexed sensor and control signals.”

IE&A director John Ehrenberg, meanwhile, points to his group’s work on such programs as wavelength-division-multiplexed local-area networks (WDM-LANs), optical built-in-test avionics, optical networks, precision image registration, tactical targeting network technology, Link 16 image processing system, and the electronics prototyping and integration center.

In addition to doing leading-edge avionics technology, IE&A is moving avionics subsystems to Boeing programs. The Advanced Electronic Systems Integration part of Phantom Works provides service to all of Boeing by reducing system and platform integration risks through applied-technology demonstrations. They bridge the technology transition gap between concept feasibility and production readiness through system prototype demonstrations in operational environments.

“EPIC is a state-of-the-art laboratory facility representing a multimillion-dollar investment specifically for electronics research and development programs,” Ehrenberg says. “A variety of activities ranging from system modeling and analysis to flight demonstrations are performed to validate concepts and reduce the risks associated with incorporation of new technologies.”

Stephen says the concept of true avionics standards-combined with real interservice, industry, and government/commercial cooperation-is vital to the future of military aviation. But it also brings an even greater requirement for long-term and cross-platform thinking.

“You can’t just say, ‘This is a Block C and everything I do only applies to this point.’ You have to be able to bring in other things later to handle additional workload, from power loading to megabits per second,” he says. “It is a totally new mindset on how to build aircraft.”