Honeywell engineers design COTS hardware into Orion advanced avionics

By Courtney E. Howard

SAN DIEGO–“Reliability is extremely important,” said Ray Crum, technical director of the NASA Orion space program at Honeywell Aerospace in Phoenix during a talk on integrating commercial electronics into the Orion spacecraft crew exploration vehicle at the Military & Aerospace Electronics Forum conference and trade show.

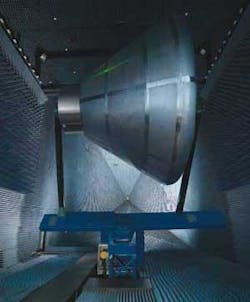

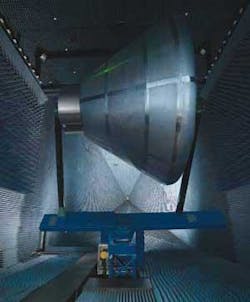

“We have to focus on that in component selection,” Crum said in describing the technologies inherent in Orion–the vehicle that will take the four-person crew to the moon. NASA officials want not only to travel to all geographic areas of the moon, which drives the propulsion requirements, but also to stay on the surface for as long as four weeks. While the crew is on the lunar surface, the Orion spacecraft will orbit autonomously. “It’s an ambitious program to set up a sustained presence on the moon,” Crum continued. Lockheed Martin Corp. in Bethesda, Md., is the prime contractor on Orion.

The crew module houses the avionics. “There are tight constraints on size, weight, and power (SWaP),” says Crum. “We have done a number of design cycles to minimize SWaP while meeting the requirements of the program.” Orion avionics include: a modern cockpit, IPv4 external communication, time-triggered Gigabit Ethernet local area network, fault tolerance, a dissimilar backup system, as well as autonomous navigation, rendezvous, and docking.

“There’s a lot of software on board to support autonomy,” Crum says. “The vehicle has to operate a lot like an unmanned satellite. We also have to provide crew situational awareness and the ability for the crew to manually take control and do so safely.”

Video is another key feature. “More video is being processed on Orion than any other spacecraft,” Crum explains. NASA would like to get high-definition video out to the worl; it is a lot of video bandwidth that has to be collected and routed, he says.

Orion is a long lifecycle vehicle; its lifetime may span 20 years. Flexibility is, therefore, key. “We want to enable the ability to grow and change the spacecraft through flexible avionics,” describes Crum. “We want to use the best parts possible in this vehicle–we are flying humans and it’s a long lifecycle vehicle–so our desire is the use the highest-reliability parts possible. Our first choice is high-reliability, rad-hard parts. Next, we look at military-grade parts because we like the ruggedization; but, one of the concerns is the radiation effects.” Then, Honeywell engineers look at commercial off-the-shelf (COTS) parts. “The bottom line is there are key performance requirements on Orion that drive COTS part usage.”