Benefits and Applications of Vertical Launch Solderless Connectors

Testing interconnect for upper microwave and millimeter-wave frequencies is intrinsically a challenge. The small geometries and extremely tight tolerances on geometries, conductor surfaces, and closely located differential signal traces place additional design burdens and create testing obstacles for high-speed data and telecommunications applications. One of the major considerations to address is how to add test ports and configurable interconnect on extremely dense circuit boards where any and every amount of conductor and insulator material must be thoroughly considered and analyzed for its impact on circuit performance.

In many cases it is undesirable to have a test port remain on a board, and solder/soldering could lead to damage or degradation of a circuit. Also, connector installation using solder, if not well controlled, could negatively impact VSWR, insertion loss, contact resistance, PIM, and other performance factors. An alternative approach would be wire bonding, but specialized machines and skilled operators are required for wire bonding, and wire bond landing pads must be external and accessible to a bonder which increases the footprint of the interconnect. Moreover, millimeter-wave interconnect isn’t inexpensive, and for larger productions of new devices the cost of shipping test port connectors could impact competitiveness of products.

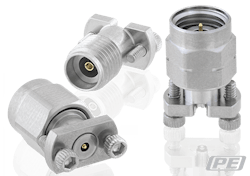

An alternative to these approaches is using recently introduced solderless vertical launch connectors. These coaxial connectors, commonly available as 2.4 mm, 2.92 mm, or SMA standard interfaces, use compression mounting technology and are oriented in a low-profile vertical launch configuration. As these connectors are tailored to microwave/millimeter-wave telecommunications and high-speed SERDES applications they are generally designed to have very low VSWR and high maximum operating frequency ranges (~50 GHz). They are also typically manufactured with gold-plated beryllium copper center contacts, stainless steel outer conductors, and high performance dielectric for long life and many reuse cycles.

What these connectors enable is for engineers to add or remove connectors from stripline and microstrip transmission lines on a wide range of circuit board thickness and compositions. With compression based connections, no solder is required and the screw mounting connections are reliable enough to use in high performance products, not just testing. During testing, however, these connectors are also much more physically robust than most probes, and don’t require any solder, adhesive, or bonding, so are ideal for non-destructive and non-interfering testing use cases.

For example, when prototyping a circuit that is connected to a larger assembly, a vertical launch solderless connector could be placed on a stripline or microstrip transmission line of the main circuit which is intended to connect to the sub-circuit, thus enabling a more similar physical layout while maintaining modularity. This method could also be much less expensive, and allow for faster turn- around then spinning out multiple board configurations just to test a sub-circuit.

Another application could be during wafer testing, where a probe station is used to place probes on a densely packed wafer and a test circuit with vertical launch solderless connectors is placed closely to the probe positioners. The low-profile vertical launch connectors could be used to limit the length of cabling required for interconnect, and could be used to easily add coaxial interconnect to otherwise stripline/microstrip internal circuitry. Other applications include vertically stacking circuit board using vertical launch solderless connectors as modular, and mechanical strong, RF interconnect between the boards while also being low-profile.

To learn more about Pasternack’s line of Vertical Launch Solderless Connectors, visit: https://www.pasternack.com/pages/rf-microwave-and-millimeter-wave-products/vertical-launch-solderless-connectors.html