The Skinny on Skin Depth and Skin Effect

The skin effect and skin depth is a rarely discussed topic, considering as it is an essential phenomenon to be aware of when working with any conductor, or semiconductor, at RF frequencies, or really anything other than DC. Essentially, the skin effect is the term to describe the way current is distributed in a conductor as a function of frequency and material properties. It can be observed that the distribution of charges in a conductor tends to travel nearer to the surface of a conductor the higher the frequency of the signal. This phenomenon affects all conductors, be it single wire, coaxial cable, microstrip, or antennas conductors.

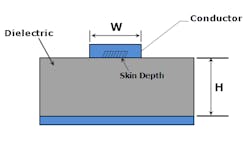

The skin effect contributes to the RF resistive losses of the conductors, but only on the conductors which are carrying the current of the propagating RF energy. For waveguide, coaxial cables/connectors, and antennas, this typically applies to the outer surface of the inner walls of the transmission line. For some microstrip and stripline structures, this could be somewhat confusing, as the inner surfaces touching the dielectric maybe the conductors carrying the current, not the outer plated surfaces. Typically, the RF losses are greater the smaller the skin depth, as the resistance at the surface of a conductor is greater. The distribution of the current through a conductor can be calculated if a few parameters are known. The distance that the majority of the charges travel within a conductor is known as the skin depth. As the skin depth is a product of frequency, resistivity, and magnetic permeability of a conductor, the RF losses of a material over frequency differ between conductor materials. For example, copper has a resistivity of 1.678 micro-ohms per centimeter and a relative permeability of 0.999991, gold has a resistivity of 2.24 micro-ohms per centimeter and a relative permeability of 1, and nickel has a resistivity of 6.84 micro-ohms per centimeter and a relative permeability of 600. The skin depth of copper, gold, and nickel at 1 GHz, is 2.06 um, 2.38 um, and 0.170 um. Hence, the RF losses for the nickel material would be the worst, while copper, and finally, gold would be far less.

Some interesting conclusion come from this phenomenon. Firstly, that a conductor’s magnetic permeability can greatly impact the RF losses of a material. Secondly, that for much higher frequencies, the majority or charges will only be traveling in a thin layer near the surface, and much thinner conductors can be used without sacrificing insertion loss performance at those frequencies.

However, just the frequency, relative permeability, and resistivity don’t tell the whole story of the RF losses of a conductor. Surface condition also greatly influences the losses, with very rough and uneven surfaces creating a much longer path, hence higher resistive losses, for the near-surface traveling current. Which is why surface roughness is a major concern in thin-film RF, and high precision millimeter-wave applications. Or, conversely any broadband application, as the insertion loss and attenuation along a conductor or transmission line will “worsen” as the frequency increases.

Check out our handy Skin Depth Calculator