HRL Laboratories helps Navy develop curved micro-bolometers to shrink and improve infrared thermal sensors

ARLINGTON, Va. – U.S. Navy researchers needed a company to reduce the size and improve the sensitivity and uniformity of wide-field-of-view infrared thermal cameras. They found their solution from HRL Laboratories LLC in Malibu, Calif.

Officials of the Office of Naval Research (ONR) in Arlington, Va., announced a $3.2 million contract to HRL Laboratories last week for the Spherical Longwave Infrared Micro-bolometers (SLIM) project.

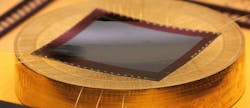

HRL engineers will curve a commercial microbolometer spherically to improve the sensitivity and uniformity, and to reduce the size and weight of wide-field-of-view cameras. HRL is an industry leader in the curving of sensors, Navy researchers say.

The company also has expertise in non-standard semiconductor fabrication and infrared fabrication, packaging, and testing, Navy officials say.

The goal of the SLIM project is to develop and deliver a curved uncooled long-wave infrared (LWIR) cameras. LWIR sensors key on the heat that targets of interest generate.

These kinds of infrared sensors are particularly useful to detecting humans and animals at night, in bad weather, and in smoke and haze by detecting the warmth of the targets against a relatively cool background. They also can detect and track the heat of vehicle engines.

LWIR sensors also are useful for detecting and targeting rocket and jet engine exhaust, and can help detect and the presence of jet aircraft without using active sensors like radar.

LWIR sensors also can be paired with light-amplification sensors to improve the night vision of warfighters who are operating after sundown, in bad weather, or in smoke and haze.

Curved imaging sensors have significant advantages over flat sensors in that they increase performance and reduce the cost, weight, and volume of optics for many types of cameras, HRL officials say.

Curved sensor technology has the potential to improve optic-related scientific fields such as computer vision and automation, reconnaissance and surveillance imaging, photography, videography, microscopy, and telescopy.

Six years ago HRL Laboratories won a contract from the U.S. Intelligence Advanced Research Projects Activity (IARPA) in Washington to develop spherically curved short-wave (SWIR) and medium wave (MWIR) infrared image sensors.

Related: NASA announces 12 companies that will collaborate on Moon-to-Mars technology

That project sought to develop improve technology understanding of the effects of bending on the performance of III-V semiconductor SWIR and MWIR image sensors. One part of the program examined the benefits of curved sensors for infrared lens design.

Infrared sensor performance is sensitive to the mechanical strain of bending, and the cooling process can affect the sensor’s performance. HRL engineers investigated the limits of bending and cooling infrared sensor material to characterize how bending can change sensor performance, and sought to determine how best to use the technology.

For more information contact HRL Laboratories online at www.hrl.com, or the Office of Naval Research at www.nre.navy.mil.