SOSA standard taking hold in military embedded computing

NASHUA, N.H. - Government and industry partners are working together to ensure that technology is vendor-neutral and easily upgradable thanks the Sensor Open Systems Architecture (SOSA) Consortium.

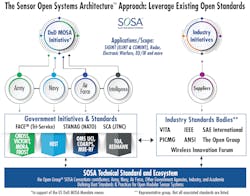

The emerging SOSA open-systems standard — overseen by The Open Group in San Francisco — aims to enable military embedded systems designers to create new systems and make significant upgrades to existing systems much more quickly than today’s technologies allow.

SOSA is heavily influencing the backplane and chassis development in military embedded computing applications, and is driving development of backplanes, chassis, connectors, high-speed switch fabrics, VME, VPX, CompactPCI, PCI Express, and embedded computing computer boards.

The high-level goals of SOSA include openness and being platform- and vendor-agnostic while being aligned with Modular Open Systems Approach (MOSA) using standardized software and hardware. The consortium aims to leverage existing and emerging open standards and align with U.S. Department of Defense (DOD) service objectives. Finally, SOSA aims to keep technology affordable and adaptable.

While the consortium buttons up its rules ahead of the pending “1.0” release, SOSA still is attracting members from the military embedded computing industry.

Continuing to add companies

In July, officials of Atrenne Computing Solutions, a Celestica company in Brockton, Mass., announced that their company has joined the SOSA Consortium.

“Atrenne fully embraces and looks forward to supporting the development of the SOSA Technical Standard for the defense industry.” says Jim Tierney, vice president of defense and aerospace systems at Atrenne. “Our long and strong history of designing and manufacturing technology geared towards the success of the military ecosystem will certainly be center stage in our collaborative efforts within the SOSA community.”

Also in July, executives of Pixus Technologies in Waterloo, Ontario, announced the launch of Pixus Technologies USA Corp. in Tonawanda, N.Y., near Buffalo.

“The opening of Pixus USA provides a convenient, U.S.-based pathway for many of our key customers,” says Justin Moll, vice president of sales and marketing for Pixus Technologies USA. “The U.S. group positions Pixus as one of the premier providers of backplanes, enclosure platforms, and specialty products in the North American embedded computer market. Our USA team will also be active in the SOSA Consortium and continue to develop SOSA aligned and OpenVPX innovations.”

Pentagon parameters

In 2019, the DOD issued a directive to the U.S. Army, Navy, and Air Force dubbed the “Tri Services Memo." The use of modular open standards is a “warfighting imperative” according to the DOD.

“After each of the three services had previously developed their own open standard initiatives, with many common elements, they all converged their efforts into the single SOSA initiative,” says Rodger Hosking, vice president of Mercury Microelectronics (formerly Pentek) in Upper Saddle River, N.J.

“Due to strong support and participation from all levels of DOD, the MIL-AERO vendor community, defense research facilities, and universities, SOSA will soon release its Technical Standard Rev 1.0,” Hosking says. “This will drive DOD procurement requirements going forward, with program awards going to those vendors submitting proposals for products and systems with high SOSA content. When released, the standard is expected to include a limited subset of OpenVPX standards and profiles including boards, backplanes, chassis and switch fabrics, but not those other form factors.”

Benefits to open standards

Mark Grovak, the director of the avionics business development segment of Curtiss-Wright Defense Solutions based in Ashburn, Va., notes that the DOD’s“This will make adoption easier and faster for the DOD,” Grovak says. “By defining common characteristics for hardware and software, SOSA mitigates vendor lock-in. Integrators are free to choose best-of-breed solutions without feeling bound to a specific vendor for fear of escalating costs and integration burden. This freedom creates more competition between vendors, as they can no longer count on recurring revenue from customers facing vendor lock-in. On the flip side, it also creates new opportunities to seize business where a competitor is the incumbent. Ultimately, it motivates vendors to engineer more innovative products, lower prices, or create new value propositions - such as life cycle management services.”

Mercury’s Hosking says that the DOD and its suppliers benefit from platform-agnostic hardware.

“The defense community benefits from platform reusability, shorter procurement cycles, easier insertion of new technology, and a stronger, multi-vendor supply chain,” explains Hosking. “Defense contractors are able to protect their intellectual property, because SOSA does not require vendors to disclose technology, software, and processes within their SOSA products. Instead, vendors will compete on innovation, performance, capabilities, and price. SOSA will benefit smaller vendors who can develop new technology SOSA products for the larger primes, helping them improve the SOSA content of their proposals to help them win awards, and also speeding delivery.”

SOSA experts at Elma Electronic in Fremont, Calif., say that SOSA helps solve problems with integrating and upgrading components in embedded military systems. “There are two long-standing problems suffered by the development of high-performance electronic systems in the mil-aero sector,” says Mark Littlefield, senior manager of ECP and systems solutions; Ken Grob, director of embedded computing technologies; and Valerie Andrew, SOSA BWG outreach committee lead, in a joint statement.

“The first is the difficulties of integration, both from components from different suppliers as well as for highly engineered custom backplanes designed specifically for the board complement chosen,” the Elma officials say. “The second is the virtual vendor-lock that the choice of boards triggers, making replacement or future upgrades from other suppliers all but impossible.”

Standards-based platforms and vendor-agnostic components address these problems by reducing development cycle time and costs, while accelerating rapid technology insertion; encouraging interoperability and commonality/reuse across multiple platforms; creating a broader vendor ecosystem for sourcing components and open competition; lowering systems integration costs and risk; and supporting improved capability evolution.

Memory experts at SMART Modular Technolgies in Newark, Calif., say that using standardized memory and storage components for MIL-AERO systems can help to reduce costs.

“Common semiconductor components — controllers, NAND Flash, DRAM, etc. — can be leveraged across many products.,” says SMART’s Michael Guzzo, who serves as the company’s senior manager. “We are seeing this on many fronts. The ability to securely attach industry standard components and to help mitigate heat has helped the mil-aero system designers bridge the gap from proprietary designs to industry standards. There are many devices available from industry including mechanical clips, adhesives and many different heat dissipation techniques.”

The experts at Elma also explain that the SOSA Consortium along with its sister consortium Future Airborne Capability Environment (FACE) are among the first in embedded hardware to be driven jointly by both industry and government.

“Previous open standards have been widely adapted by the defense and government agencies, those standards were primarily driven by industry, with the subsequent products being implemented into custom or semi-custom integrated solutions delivered by prime integrators and contractors,” Elma officials explain. “It should also be noted that SOSA — and related open systems efforts — are going to have a profound impact on the embedded systems development community worldwide — well beyond the core SOSA community. The ease of system design and integration that SOSA aligned products enable, along with the potential for breaking vendor-lock regarding future technology insertions can be enjoyed by anyone worldwide. We are already seeing activity in both the UK and Europe that shows a real up-tick in interest in the SOSA Technical Standard, and the first real market interest in SOSA aligned products.”

Seamless sharing

“These solutions are designed to operate in isolation and, as a result, are difficult and time-consuming to deploy on platforms where systems and people must work together to ensure personnel safety and mission success,” Grovak says. “One of the main benefits of leveraging common standards is that it ensures interoperability between sensors and systems. Sensor data and system output can be seamlessly shared between machines on the same platform, providing complete and accurate situational awareness.

“This capability is particularly critical in GPS-degraded or -denied environments, for example, Grovak continues. “When factors such as tall buildings, heavy foliage, underground positions, or adversaries compromise GPS signals, warfighters rely on data from multiple technologies to arrive at a positioning, navigation, and timing (PNT) truth. Assured PNT (A-PNT) computing solutions must amalgamate and process data from these sources exceptionally quickly. Once processed, this information must be made available to various systems and clients on the platform.”

Cooling challenges

While SOSA experts agree that the open standard approach benefits both industry and the military, there are still challenges in keeping compact embedded systems cool.

“One of the key challenges of new SOSA configurations is cooling the chassis,” says Pixus’s Moll. “With plug-in OpenVPX boards that are often more than twice as hot as they were just a few years ago, it is critical to ensure proper thermal management. One such example where this problem is resolved is Pixus’s OpenVPX chassis for 6U boards that leverages a VITA 48.8 airflow approach. Thermal simulation is also increasingly important to utilize in developing SOSA systems and can point to the best cooling strategy.”

In addition to keeping systems cool, Curtiss-Wright’s Grovak explains that industry still needs to meet the DOD’s size, weight, power, and cost (SWaP-C) needs.

“Historically, adding functionality meant equipping a vehicle with a new standalone system — a.k.a., the ‘bolt-on’ approach. Each of these line replaceable unitsGrovak says that Curtiss-Wright offers a wide variety of embedded computing aligns with the SOSA technical standard, including the company’s the VPX3-1260 family of high-performance single-board computers for demanding defense and aerospace applications like mission computing; image and display processing; and intelligence, surveillance, and reconnaissance (ISR) systems.

Based on Curtiss-Wright’s VPX3-1260 core design, the computer boards have the 9th Gen Intel Coffee Lake Refresh Xeon E-2276ME processor, to speed and simplify the integration of the Xeon E processor’s cutting-edge capabilities.

The I/O Intensive computer board variant of the VPX3-1260 provides a DisplayPort video interface that supports hardware-accelerated graphics to 4K resolution. It also offers PCI Express expansion, USB and SATA storage interfaces, and external serial and GPIO/DIO connections. An on-board XMC mezzanine site supports expansion options.

Moll highlights the Pixus quick-turn development chassis, which is aligned with the SOSA technical standard.

“The highly versatile open frame enclosure has four VPX slots and four VITA 67.3c slots which are common to SOSA boards,” Moll says. “The PSU is modular and the fan speed is adjustable with a dial. “The power and ground only backplane offers SOSA clocking as well as configurable options to accept profiles like the 14.6.11 configuration that have a special grounding row in the connector wafer. Customers can use Meritec cables to route the slots as needed.”

Mercury’s Hosking says the company’s the Quartz RFSoC Model 6003 was made with the SOSA technical standard in mind.

All control and data paths are accessible by the RFSoC’s programmable logic and processing system. The Xilinx Zynq UltraScale+ RFSoC Gen 3 integrates eight RF-class A/D converters and D/A converters into the Zynq FPGA fabric along with quad ARM Cortex-A53 and dual ARM Cortex-R5 processors, creating a multichannel data conversion and processing solution on a single chip.

The QuartzXM Model 6003 is pre-loaded with a suite of IP modules to provide data capture and processing solutions for many common applications. Modules include DMA engines, DDR4 memory controller, test signal and metadata generators, data packing and flow control. The board comes pre-installed with IP for triggered waveform and radar chirp generation, triggered radar range gate engine, wideband real-time transient capture, flexible multi-mode data acquisition and extended decimation.

About the Author

Jamie Whitney

Senior Editor

Jamie Whitney joined the staff of Military & Aerospace Electronics in 2018 and oversees editorial content and produces news and features for Military & Aerospace Electronics, attends industry events, produces Webcasts, and oversees print production of Military & Aerospace Electronics.