China's 3D-printed mini jet engine flies to 13,000 feet in first test

BEIJING - China has conducted a successful maiden flight of a miniature turbojet engine manufactured entirely with 3D printing, a development that explores new methods for tackling difficulties in aerospace propulsion, Aman Tripathi writes for Interesting Engineering. Continue reading original article.

The Military & Aerospace Electronics take:

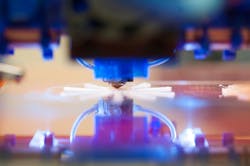

7 July 2025 - China has successfully flight-tested a domestically developed turbojet engine in Inner Mongolia, marking a milestone in its aerospace manufacturing. The engine, in the 160-kilogram (353-pound) thrust class, reached altitudes of up to 13,000 feet and was created entirely using additive manufacturing and topology optimization. This approach utilizes computer modeling to design lightweight yet strong components, which are then fabricated via 3D printing, thereby bypassing traditional casting and forging methods.

While 3D printing in aerospace is not new -Western firms like GE and RTX's Pratt & Whitney have used the technology for years - AECC’s full-engine production via additive methods is notable. If scalable, it may accelerate prototyping and production, particularly for applications such as high-speed, uncrewed aerial vehicles (UAVs).

Related: The evolution of 3D printing and additive manufacturing

Related: NASA additive manufacturing project shapes future for agency, industry rocket makers

Jamie Whitney, Senior Editor

Military + Aerospace Electronics