Energy storage for military applications faces demands for more power

NASHUA, N.H. - Mobile electronics for the battlefield go hand-in-hand with batteries, and have done so for years. It’s not news that electronics that can’t be plugged-in relies on the energy-storage medium of batteries. What’s new, however, is the growing reliance on batteries and other kinds of energy-storage media for sophisticated electronics that, despite their mobility, demand ever-growing amounts of power.

“The military is primarily concerned with off-grid operations,” explains Dominic Perez, chief technology officer at the Curtiss-Wright Corp. Defense Solutions Division in Ashburn, Va. Curtiss-Wright engineers view energy-storage design issues from the standpoint of a systems integrator.

“The military needs the power to sustain that mission,” Perez continues. “I am sure there are military folks who are looking, for example, at fully electric militaryThe biggest energy-storage concerns of manufacturers and systems integrators revolves around power-storage issues like electrical capacity and discharge rate. Still, other concerns are nearly as important, such as industry standards and certification, safety, a reliable supply chain, battery form factors, battery technologies, and even alternatives to batteries like capacitors, generators, and solar power generation

Power storage

“For aviation, especially, they need more power, and they need more energy for fixed-wing and rotary aircraft,” says Kyle Roelofs, vice president of business development at battery designer Bren-Tronics Inc. in Commack, N.Y. “They want to use all the electronics at their disposal.”

For batteries in aviation applications, size and weight are crucial considerations. The trick is to pack as much electrical energy as possible into the smallest package. “Higher densities and different form factors are very compelling,” says Curtiss-Wright’s Perez.

A prime consideration is balancing the battery’s storage capacity and energy-discharge rate to the needs of the target application. Capacity refers to the total amount of electricity a battery can hold, and discharge rate describes the speed at which the battery can supply its application. Discharge rate isn’t trivial; some applications need a lot of power quickly, while others need a low and steady flow to maintain their operation over time.

“There is a lot that goes into battery design, and it is a tradeoff between discharge rate and capacity,” Perez explains. “You can have a large capacity, but will give-up some of that discharge rate.” Curtiss-Wright systems integrators typically look for sustained discharge rate, or energy storage that lasts for a relatively long time.

Battery designers also can design computer control into their batteries, or smart batteries, which offers advantages like cutting-off a charge once the battery has reached its capacity, or reducing the battery’s discharge rate when its power level gets low.

Industry has formulated an open-systems standard called Smart Battery System (SBS) that enables software operating systems to perform power management and battery charge rate via a smart battery charger. The Smart Battery System defines the SMBus connection. Virtually any battery operated product can use SBS.

A special integrated circuit in the battery pack called a fuel gauge or battery management system monitors the battery and reports information to the SMBus. This information might include battery type, model number, manufacturer, characteristics, charge and discharge rate, predicted remaining capacity, temperature, voltage, and an almost-discharged alarm so that the PC or other device can shut down gracefully.

Lithium-ion batteries

Batteries with the largest energy capacities today are lithium-ion batteries, which are promising for a wide variety of applications ranging from electric cars toLithium-ion batteries are rechargeable, feature low self-discharge, and are among most promising technologies, but are the newest and least-proven. Although they offer superior energy capacities and a variety of power discharge rates, these batteries still can be hazardous if mishandled, and are restricted in their uses — especially in aviation.

“We are 90 percent lithium-ion batteries,” Roelofs says. “It has a sweet spot in soldier-worn applications, where the market has been all-lithium-ion for years. Today, all new vehicles will be lithium-ion. Everyone is moving to lithium-ion where they look to provide more energy and power.”

Still, these batteries have their downsides. They contain flammable electrolytes and if damaged or incorrectly charged can lead to explosions and fires. “Lithium-ion batteries are new, and there are potential issues of it not working on what is fielded,” Roelofs says. “Lithium-ion is more expensive than some other battery technologies.”

One of the biggest concerns of lithium-ion technology is safety. “Lithium-ion is the same chemistry as your cell phone in your pocket,” Roelofs points out. “Unlike lead-acid batteries, however, if you do puncture them it could have an event. It could vent, have smoke, gas, or flames.”

Researchers are trying to extend the lifetime of lithium-ion battery technology, increase its energy density, improve safety, reduce cost, and increase charging speed. Researchers also are considering using non-flammable electrolytes for increased safety.

“I would estimate that lithium-ion today is fractional for use on aircraft,” Roelofs says. “today it is a very low percentage, but that will be trending higher in the future. Lithium-ion will grow, but it will be a slow process. In the near term, lithium-ion will replace other battery technologies in wide swaths. It will be niche for a while, and will be used in places where they need more energy, in which lead-acid can’t provide it.”

Despite its advantages, lithium-ion isn’t for everybody. For aviation, the choices today predominantly are for nickel-cadmium or sealed lead-acid batteries, Roelofs says. Demand for those kinds of traditional battery technologies typically comes from long-term contracts, or even from warfighters buying directly for their units, he says.

Battery certification

For aerospace and defense applications, certification issues often are just as important as technology issues, which requires long-term planning for battery upgrades or system redesigns that involve new batteries. “You just can’t take an approved battery and swap it out with something new without acquiring the proper certification for it,” says Bren-Tronics’s Roelofs. “It’s a three-year, or longer process to get a battery approved.”

Curtiss-Wright specializes in embedded computing, rugged computing, and battlefield networking systems, which can require batteries for backup and other uses. The company uses batteries that are certified by the U.S. Department of Transportation (DOT), the Department of Defense (DOD), and the International Air Transport Association (IATA), among others, Perez says.

“Our batteries also must be assigned a national stock number (NSN),” Perez says. “It is important that we not have to certify unique batteries. They need to have that NSN and the proper certifications.”

Obtaining batteries with the correct certifications typically isn’t difficult for Curtiss-Wright. “If it is a standard product line offering, then the manufacturers know that it is part of the process,” Perez says.

Time-to-market pressures, however, sometimes can induce battery companies to certification as a less than top priority, and Perez says he understands. “Like anyone, they want to secure the technology first, patent it if necessary, and announce it to customers without having to wait for that certification and regulation process.” Still, Perez encourages his suppliers to keep certification at the top of their planning.

In addition to certification, systems integrators who design-in batteries also are looking for standard form factors, Perez says. “We use the 2590 form factor battery. It has been upgraded over time, and Bren-Tronics is one of our key partners. They have been able to increase the power density of these batteries over almost anything else on the market.”

Non-battery power storage

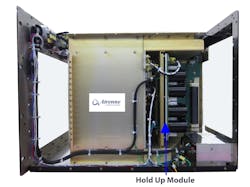

Considerations about battery safety, reliability, size, weight, and certification sometimes put batteries out of bounds for some applications — particularly in military and commercial aviation. “For the most part, we rarely use batteries in any aviation hardware; often batteries are forbidden,” says David Masucci, programFor applications where batteries are not allowed, Atrenne relies on capacitors for holdup power, which provides short-term electricity for applications such as commercial airline gates in which power to critical systems must be maintained when the aircraft disconnects from airport power before the aircraft can get power from its engines.

“They need power for a 50-to-200-millisecond duration as the plane disconnects from the gate,” Masucci says. Atrenne designs VPX embedded computing systems that contain a holdup-power module for just these kinds of uses.

“Most of the equipment we do has built-in CPUs, and if there were a power glitch, these systems would reset, and then you have to wait for them to reboot,” he says. “In a critical military situation, this could be deadly.”